Composite drill bit

A composite drill bit and bit body technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems that affect the rock-breaking efficiency and service life of the drill bit, and the cutting teeth wear fast, so as to eliminate adverse effects, smooth movement, Effects of Improving Mounting Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

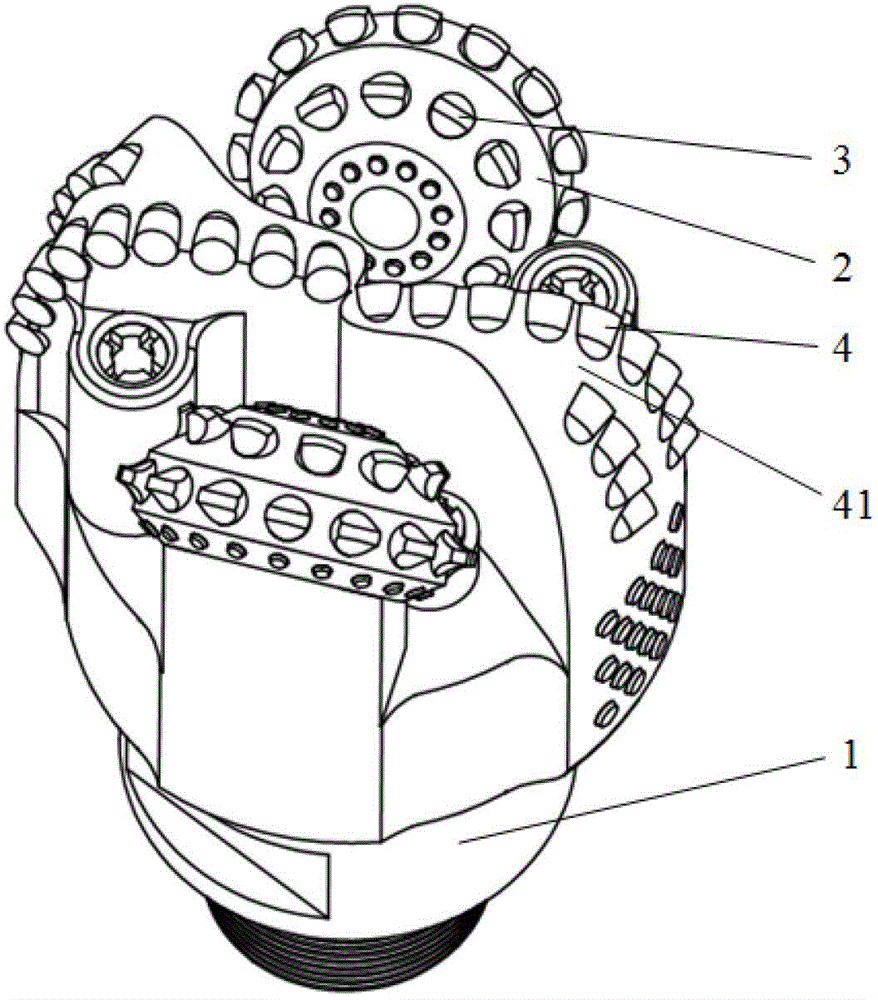

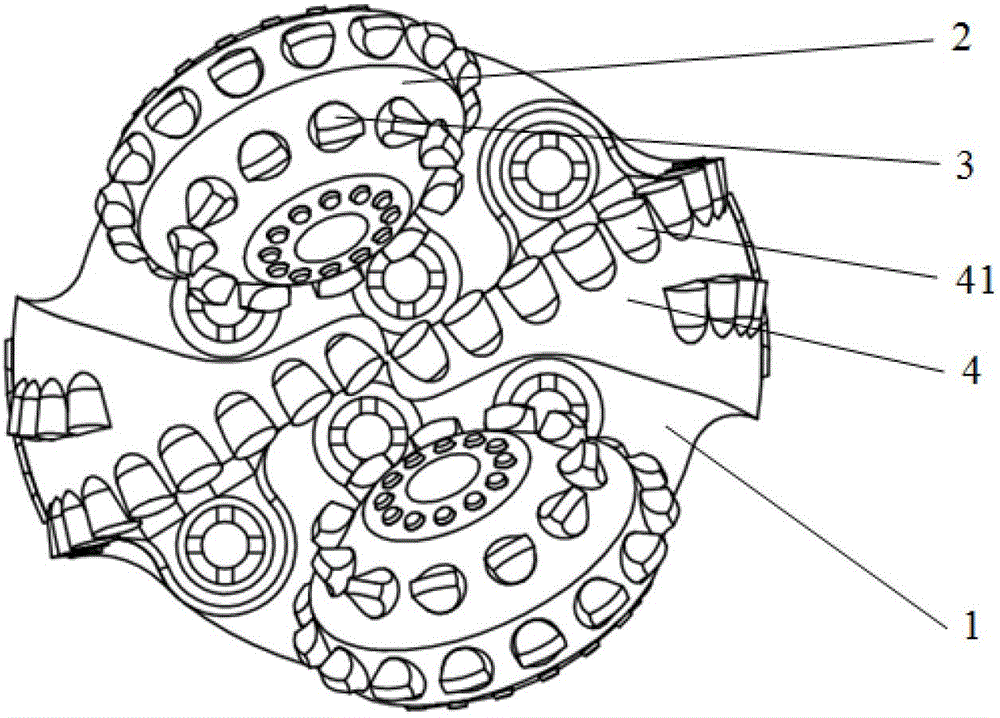

[0045] see Figure 1 to Figure 12 Shown, a kind of composite drill provided by the present invention, the embodiment of the present invention uses figure 1To illustrate, the composite drill bit includes a drill body 1, a fixed cutting structure (fixed wing in the figure) 4 and at least one cone 2, and the cone 2 and the fixed cutting structure 4 are arranged on the drill body 1, the cone 2 forms a rotational connection with the bit body 1 through a bearing structure;

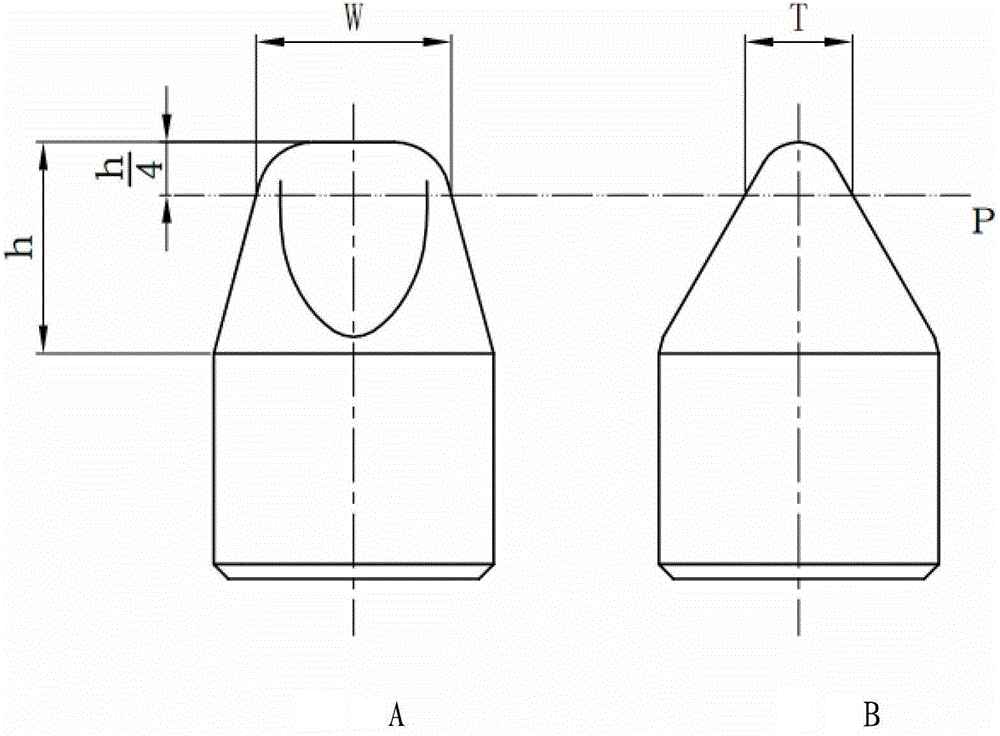

[0046] The tooth wheel 2 is inlaid with a horizontally mounted tooth 3, and the value range of the deflection angle α of the tooth top of the horizontally mounted tooth 3 is 70°≤|α|≤90°, and the width W of the tooth top of the horizontally mounted tooth 3 is not The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com