Coal bed roadside pressure relief zone width measuring system and method based on drill hole gas leakage

A measurement system and pressure relief zone technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve problems such as large influence, uncertainty in measurement results, and inability to achieve fixed-point sampling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

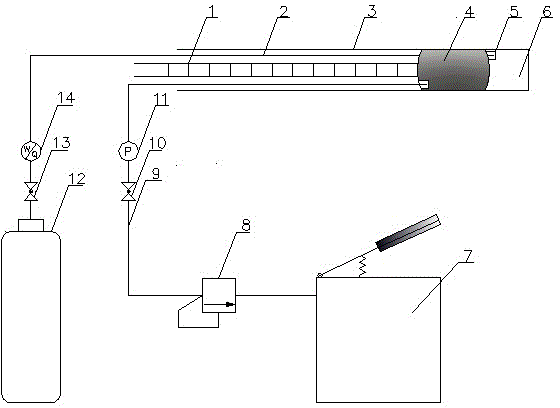

[0021] Depend on figure 1 The shown coal seam roadside pressure relief belt width measurement system based on the amount of drilling gas leakage includes a seepage gas pipeline 2, a connecting rod 1 and a sealing capsule 4 arranged on the connecting rod 1, and the sealing capsule 4 is fixed on the The end of the connecting rod 1, the sealing capsule 4 is an elastic capsule, and the sealing capsule 4 is connected with a fluid filling mechanism. The fluid filling mechanism includes a water injection pipeline 9 and a hydraulic pump 7, an overflow valve 8, a water injection pipeline switch valve 10 and a pressure gauge 11 arranged sequentially on the water injection pipeline 9, and the port of the water injection pipeline 9 is connected to the sealing capsule 4. The hydraulic pump 7 is a manual hydraulic pump. When filling the sealing capsule 4 with water, the hydraulic pump 7 is also connected to a water source. The water source can be a water tank or other water sources. Of cou...

Embodiment 2

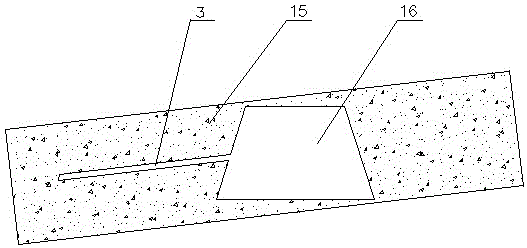

[0025] Depend on figure 1 and figure 2 The pressure belt measurement method of the coal seam roadside pressure relief belt width measurement system based on the amount of drilling gas leakage shown includes the following steps: (1) preparing the coal seam roadside pressure relief based on the amount of drilling gas leakage described in Example 1 The belt width measurement system, according to the excavation time of the roadway 16 in the coal seam 15, estimates the minimum depth of pressure relief of the roadway 16 (such as 3m or 5m) according to experience, and passes the drill pipe (the end of the drill pipe is provided with a drill bit) from the coal seam roadway 16 On the side of the roadway, construct a layer-by-layer drill hole 3 to a certain depth (such as 3m or 5m), and then withdraw the drill pipe. Before withdrawing the drill pipe, the drill cuttings in the drill hole 3 should be cleaned to ensure that the drill hole 3 is straight and smooth;

[0026] (2) Use the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com