Golf club type non-elastomer flexible seal adapting to rotor impact load

A technology of golf clubs and golf clubs, which is applied to the sealing of engines, mechanical equipment, engine components, etc., and can solve the problems of PTFE oil seal failure, large leakage, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings:

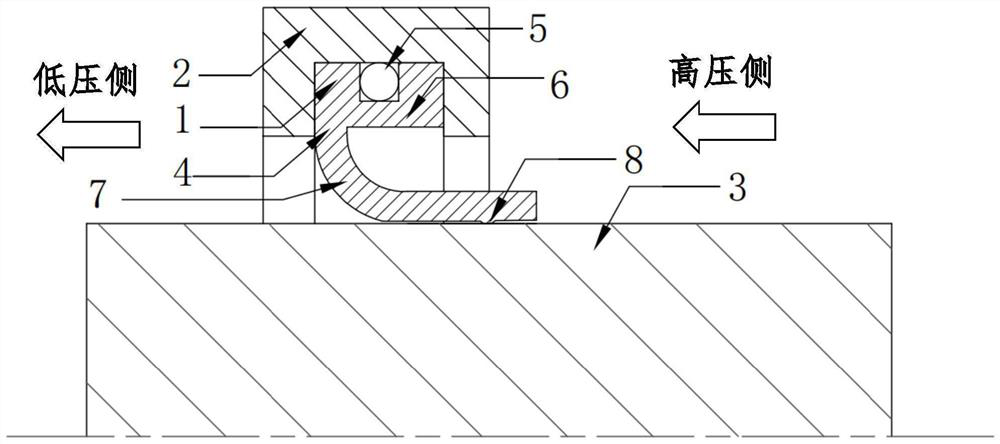

[0023] combine figure 1 , a golf club-type non-elastomeric flexible seal 1 adapted to the impact load of the rotor is arranged between the stator 2 and the rotating shaft 3, and a golf club-type non-elastomeric flexible seal 1 adapted to the impact load of the rotor is a dynamic Seals, also known as rotary seals. In operation, a golf club-type non-elastomeric flexible seal 1 adapted to the impact load of the rotor remains stationary, and the rotating shaft 3 rotates at a certain speed.

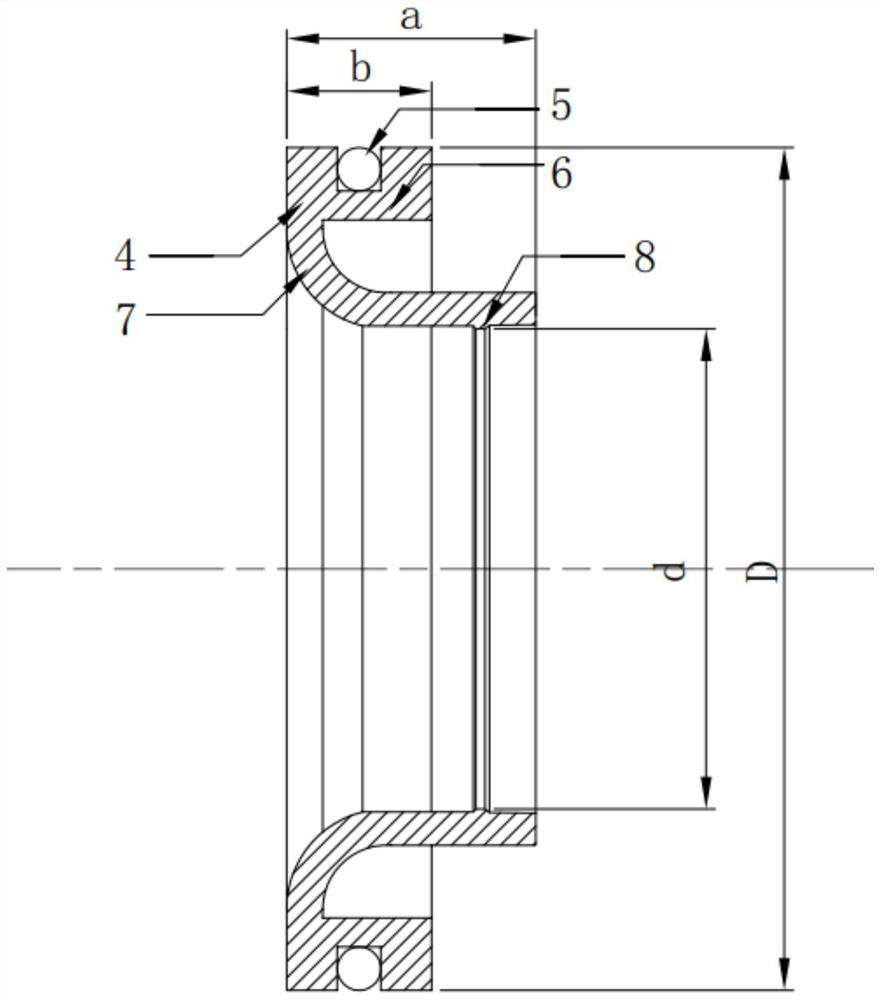

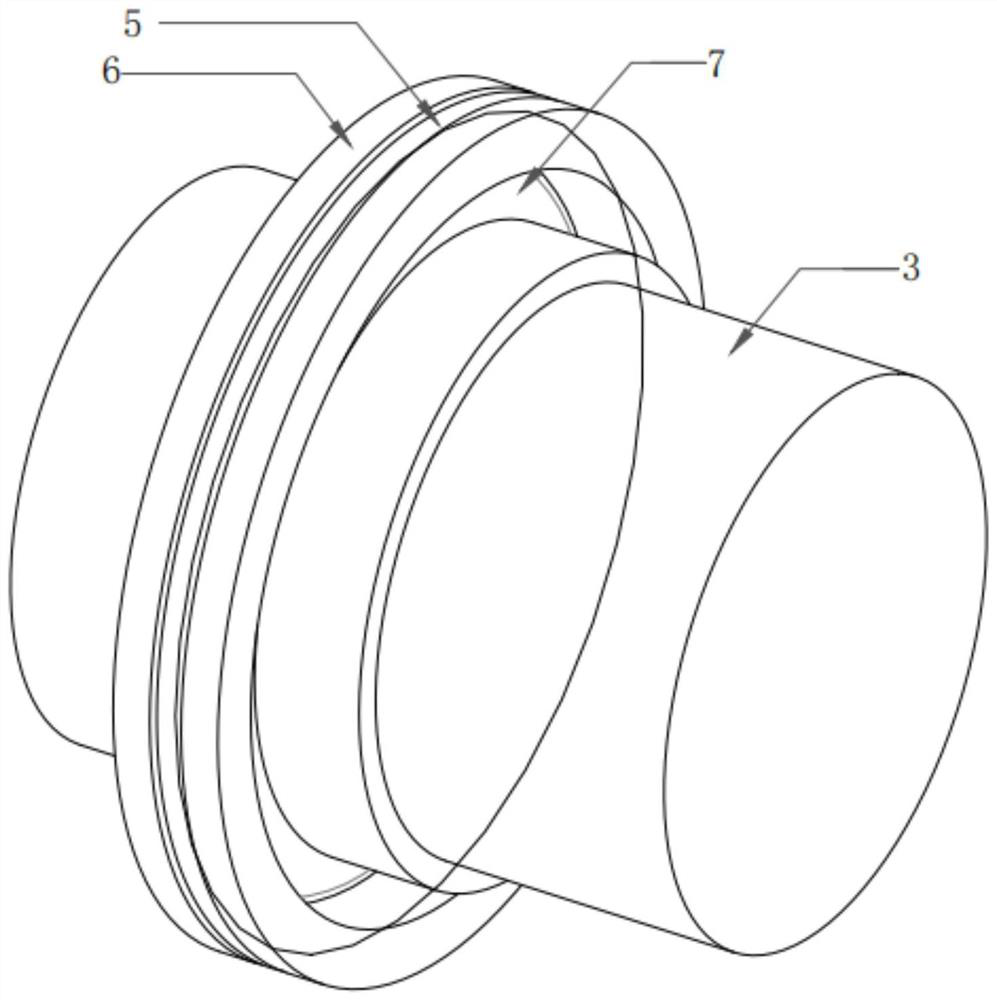

[0024] combine Figure 1-3, a golf club-type non-elastomeric flexible seal 1 that adapts to the impact load of the rotor is composed of a golf club body sealing ring 4 and an O-shaped sealing ring 5 . The golf club body sealing ring 4 is the sealing body, and the O-ring 5 is responsible for continuously providing pre-tightening force and elastic force for the golf club body s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com