Optical diffusion plate for LED (Light Emitting Diode) lamp

An optical diffusion and diffusion plate technology, applied in the field of light diffusion plates, can solve the problems of inability to maximize the use of LED light rays, inability to recycle and reuse, and material pollution to the environment, so as to improve the utilization rate of light and solve the problem of partial lighting angle. Small, soft light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

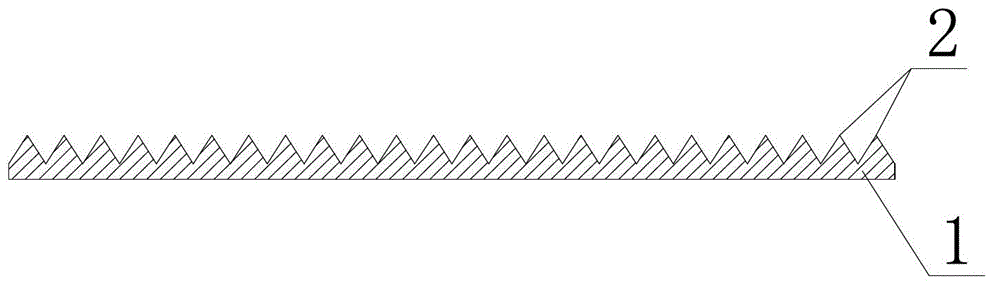

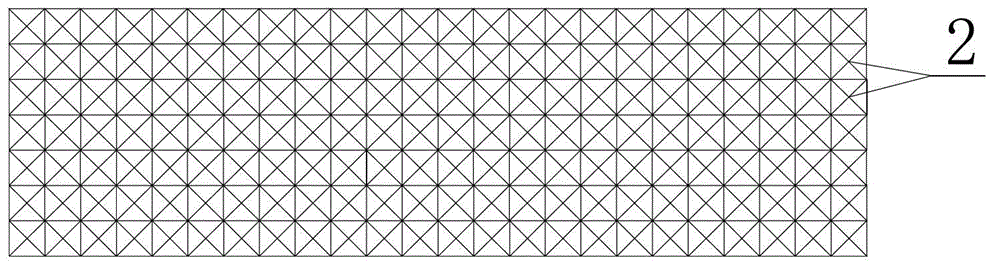

[0025] refer to figure 1 and figure 2 As shown, an optical diffuser plate for LED lights of the present invention includes a transparent first support plate 1, the first support plate 1 is a flat plate structure, and a number of first support plates are distributed on one side of the first support plate 1. Light refraction floating point 2, each of the first light refraction floating points 2 is a quadrangular pyramid, and each adjacent quadrangular pyramid is close together; the bottom surface side length of each quadrangular pyramid is 0.5 ~ 5mm, and the height is 0.4-4.3 mm, that is, the side triangles of each quadrangular pyramid are equilateral triangles. In this embodiment, the first support plate 1 and the first light refraction floating point 2 are integrally formed as an integral structure, which can be directly cast and formed, and the processing is very convenient. Because the first support plate 1 and the first light refraction floating point 2 No chemical raw m...

Embodiment 2

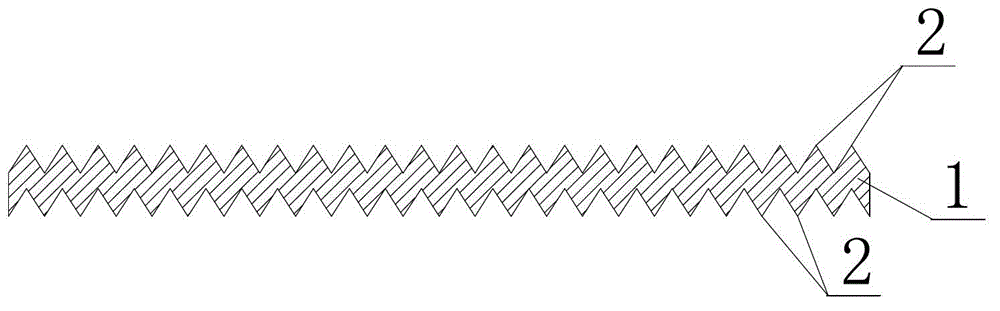

[0027] refer to image 3 As shown, an LED light optical diffuser plate of the present invention has basically the same structure as that of Embodiment 1, except that first light refraction floating points 2 are distributed on both sides of the first support plate 1, and the The first ray refraction floating point 2 located on both sides is misplaced. The diffusion plate with this structure has better diffusion effect, larger irradiation angle, better anti-glare effect and softer light.

Embodiment 3

[0029] refer to Figure 4 As shown, the structure of an optical diffuser cover for LED light of the present invention is basically the same as that of Embodiment 1, the difference is that a second support plate 3 is provided above the first support plate 1, and the first support plate 1 and the second support plate The two support plates 3 are connected by connecting rods 4; on the upper side of the second support plate 3, some second light refraction floating points 5 are distributed, and according to specific needs, they can also be distributed on the lower side of the second support plate 3, Each of the second light refraction floating points 5 is a quadrangular pyramid; the length of the bottom surface of each quadrangular pyramid is 0.5-5 mm, and the height is 0.4-4.3 mm; further, the first support plate 1 and the second support plate The distance between 3 is 0-5 mm. In this embodiment, the second support plate 3 is superimposed on the upper end of the first light refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com