Light guide plate, optical diaphragm, backlight module, array substrate and liquid crystal module

An optical film and array substrate technology, applied in optics, optical elements, nonlinear optics, etc., can solve the problems of uneven viewing angle characteristics of liquid crystal, gray scale reversal color, shift and other problems, so as to overcome the viewing angle dependence problem, prevent the light leak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

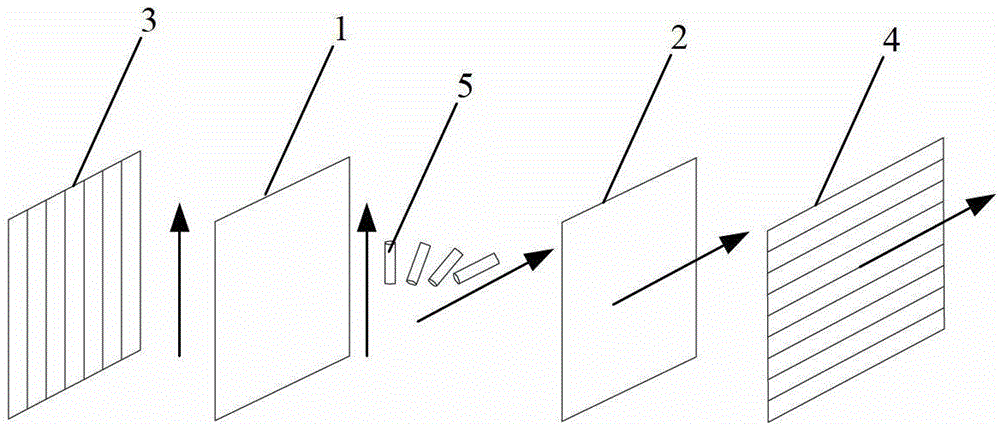

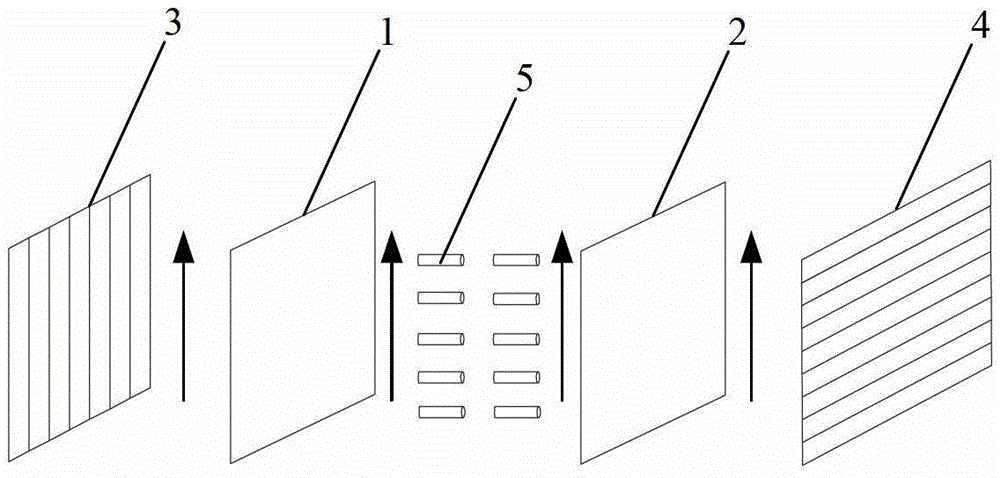

[0035] combine Figure 5-Figure 7 As shown, in order to achieve the purpose of parallel incident of light rays into the array substrate along the same angle, a light guide plate is provided in this embodiment, and a reflective layer 10 and a light concentrating layer 11 are formed on one surface of the light guide plate 9, specifically, by The reflective layer 10 and the light concentrating layer 11 are respectively formed on one surface of the light guide plate 9 by processes such as coating, deposition, and sputtering. Wherein, the reflective layer 10 is positioned under the light concentrating layer 11, and a plurality of small holes 12 are arranged on the reflective layer 10, so as to form a point light source at the position of each small hole 12, and the light concentrating layer 11 is opposite to each point light source. The rays are converged so that the outgoing rays are parallel rays traveling in the same direction, such as Figure 8 shown. Generally, the light is ...

Embodiment 2

[0039] Obviously, in order to achieve the purpose of parallel incident of light rays into the array substrate along the same angle, not only a reflective layer and a light concentrating layer can be formed on one surface of the light guide plate, but also a reflective layer and a light concentrating layer can be arranged between the light guide plate and the array substrate. A multi-layer optical film, wherein the reflective layer is located under the light-gathering layer, and a plurality of small holes are arranged on the reflective layer. Its specific working principle is the same as that in the first embodiment. Similarly, the light concentrating layer can be designed to have a plurality of microlens structures, and the small holes on the reflective layer correspond to the positions of the microlens structures one by one, and are located at the focal point of the microlens structures, so that the light rays can be emitted from the light concentrating layer in parallel. The...

Embodiment 3

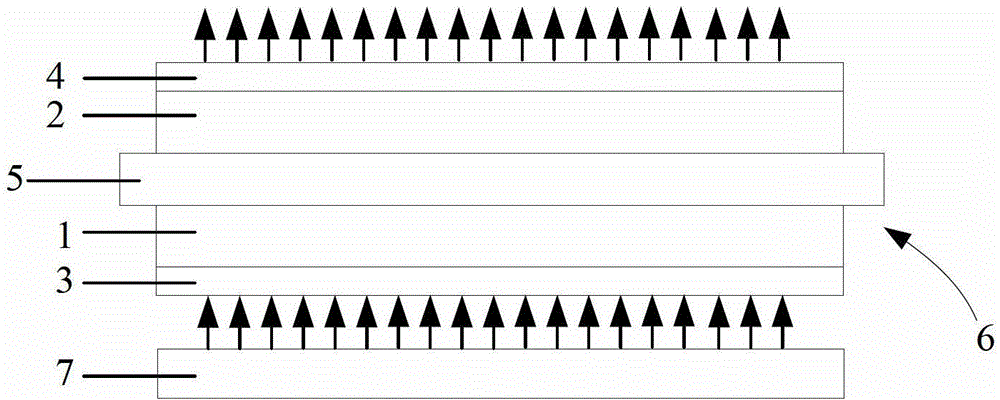

[0041] Correspondingly, this embodiment provides a backlight module, which includes a light guide plate and an optical film located above the light guide plate, wherein the light guide plate adopts the light guide plate in Embodiment 1, or the optical film adopts the light guide plate in Embodiment 2 The optical film can realize that the light is incident on the array substrate in parallel along the same angle, and no light is incident on the array substrate in other directions, thereby preventing light leakage caused by different viewing angles, while the light seen by the user from other viewing angles It is the result of the scattering of light at this angle on the surface of the display panel, ensuring that the brightness is the same when users watch the screen from different angles, thus overcoming the viewing angle dependence problem of TFT-LCD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com