Micro-displacement thickness measurement method for lithium battery film

A lithium battery, micro-displacement technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as inability to accurately measure film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

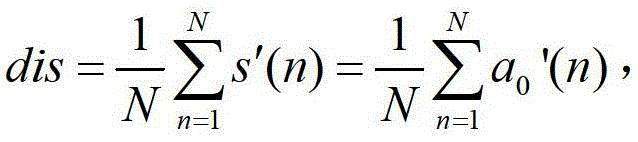

[0063] The micro-displacement thickness measurement method of lithium battery film of the present invention comprises the following steps:

[0064] Step 1. Static error suppression of laser thickness measuring device:

[0065] Step 1.1, take a gauge block with a thickness of M and place it in parallel between the upper laser sensor and the lower laser sensor of the laser thickness measuring device, and measure the distance data between the upper laser sensor and the upper surface of the gauge block, which is recorded as s 1 (n), measure the distance data between the lower laser sensor and the lower surface of the gauge block, denoted as s 2 (n), record the sampling times as n, n=1,2,...N, N is the maximum sampling times;

[0066] Step 1.2, according to the formula s(n)=M+s 1 (n)+s 2 (n), to obtain the vertical spacing data between the upper laser sensor and the lower laser sensor, denoted as s(n);

[0067] Step 1.3, adopting 7-layer wavelet processing to s(n), the obtained...

Embodiment 2

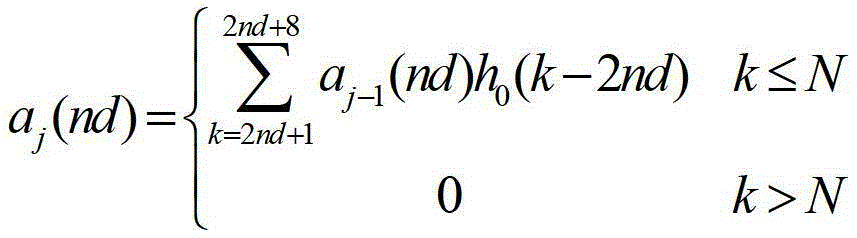

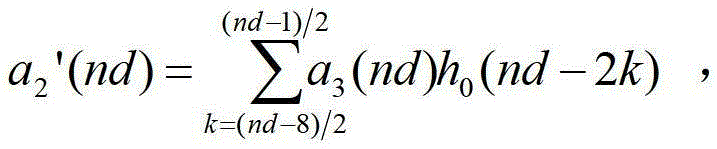

[0105] In the lithium battery film micro-displacement thickness measurement method of embodiment 1, the described 7-layer wavelet processing specifically includes the following steps:

[0106] Step a, adopt 7 layers of wavelet processing to s(n), record a 0 (n)=s(n), a 0 (n) is the coefficient that wavelet decomposition has not been carried out for the low frequency band;

[0107] Step b, calculate according to the following recursive formula:

[0108] a j ( n ) = Σ k = 2 n + 1 2 n + 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com