Aerial bare cable utilizing microform sensing optical unit for temperature measurement and strain sensing

A technology for sensing light and micro shapes, which is applied in the fields of cables, overhead bare wires and submarine cables, can solve the problems of low sensitivity and poor real-time performance of optical fiber distributed sensing, and achieve the effect of real-time response embedding process, high sensitivity and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

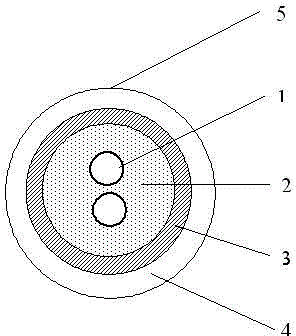

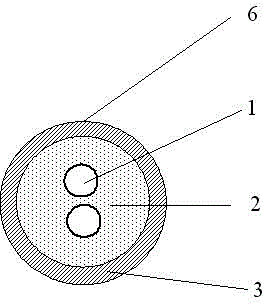

[0028] Such as figure 1 with 2 The micro-shaped sensing optical unit shown is embedded in the inside or outside of the cable. It includes a micro-shaped sensing optical unit body. The micro-shaped sensing optical unit body includes a sensing optical fiber 1, and the sensing optical fiber 1 is covered with a sealed Stainless steel tube 3, the stainless steel tube 3 is filled with water-blocking fiber paste 2; the number of sensing optical fibers 1 is 1 or 2 or more, and the range of the excess length of the fiber in the stainless steel tube 3 is: 0≤excess length <0.03% . The stainless steel tube 3 may also be covered with a sheath 4.

[0029] The micro-sensing light unit is manufactured by special equipment. The protective tube of the micro-sensing light unit is usually made of a stainless steel tube 3 with a thickness of 0.15mm-0.2mm through molding, laser welding, and sizing drawing. The protective tube is formed on the stainless steel tube 3. Input the optical fiber 1 for sens...

Embodiment 2

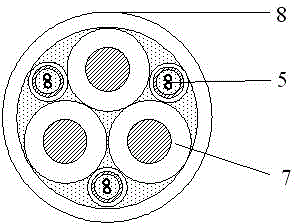

[0031] Such as image 3 with 4 As shown, the cable for temperature measurement using the micro-shaped optical sensing unit described in Example 1. The cable includes a cable conductor core 7 and a cable outer sheath 8, and also includes a micro-sensing optical unit and a stainless steel tube of the micro-sensing optical unit 3 is wrapped with a sheath 4, and the miniature sensing light unit 5 with the sheath and the cable conductor core 7 are simultaneously twisted inside the cable or wound around the outer sheath 8 of the cable. In this embodiment, due to the insulation requirements of the cable, a sheathed micro-shaped sensor optical unit 5 is generally used. image 3 It is a schematic diagram of the cable structure for detecting the internal temperature of the cable. The sensor light unit 5 with a sheath can be one or more. image 3 In the middle are 3 sheathed sensing light units 5 and the cable core wires are twisted synchronously. Figure 4 It is a schematic diagram of the ...

Embodiment 3

[0033] Such as Figure 5 As shown, the duct optical cable for strain sensing using the micro-sensing optical unit described in Embodiment 1. The duct optical cable includes a conventional communication optical unit 9 and an optical cable outer sheath 11, and also includes a micro-sensing optical unit and a micro-sensing optical unit The miniature sensor optical unit 6 without a sheath and without a sheath and the conventional communication optical unit 9 are simultaneously twisted inside the pipe optical cable. The outer diameter of the micro-shaped sensing optical unit 6 without a sheath is matched with the gap of the conventional communication optical unit 9 so that it is tangent to the circular track formed by the conventional communication optical unit 9.

[0034] Such as Image 6 As shown, the buried optical cable for strain sensing using the micro-shaped sensing optical unit described in Embodiment 1. The buried optical cable includes a conventional communication optical uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com