Method for determining cut stem proportion in cut tobacco

A method of determination and shredded tobacco technology, which is applied in the direction of weighing by removing certain components, can solve the problems of low detection accuracy, complicated operation, scrapped shredded tobacco, etc., and achieve an optimized blending method, simple and fast operation, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

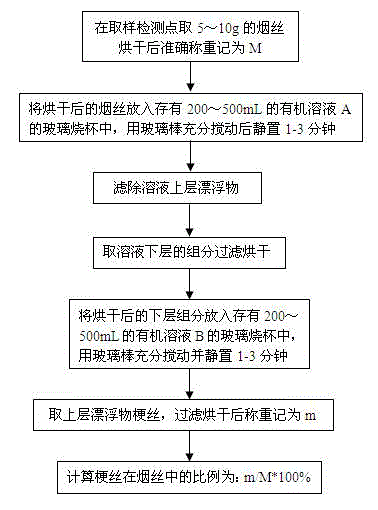

[0022] Such as figure 1 As shown, the present embodiment provides a method for measuring the proportion of shredded stems in shredded tobacco, comprising the following steps:

[0023] Step 1: Take 5-10g, preferably 10g, of shredded tobacco at the outlet of the silk storage cabinet, and after drying, accurately weigh and record it as M;

[0024] Step 2: Put the dried shredded tobacco into a storage tank of 200-500mL, preferably 250mL, with a density of 0.47-0.93g / cm 3 , preferably 0.68g / cm 3 In a glass beaker of acetone, fully stir with a glass rod and let it stand for 1 minute, and filter off the floating matter in the upper layer of the solution;

[0025] Step 3: Take the components of the lower layer of the solution, filter and dry them, and put the dried lower components into a storage tank of 200-500mL, preferably 250mL, with a density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com