Twenty-high rolling mill backing roller convexity adjusting device

A technology of adjusting device and rolling mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of slow command response speed, unable to adjust with load, long correction time, etc. The effect of convenience, improved response speed and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

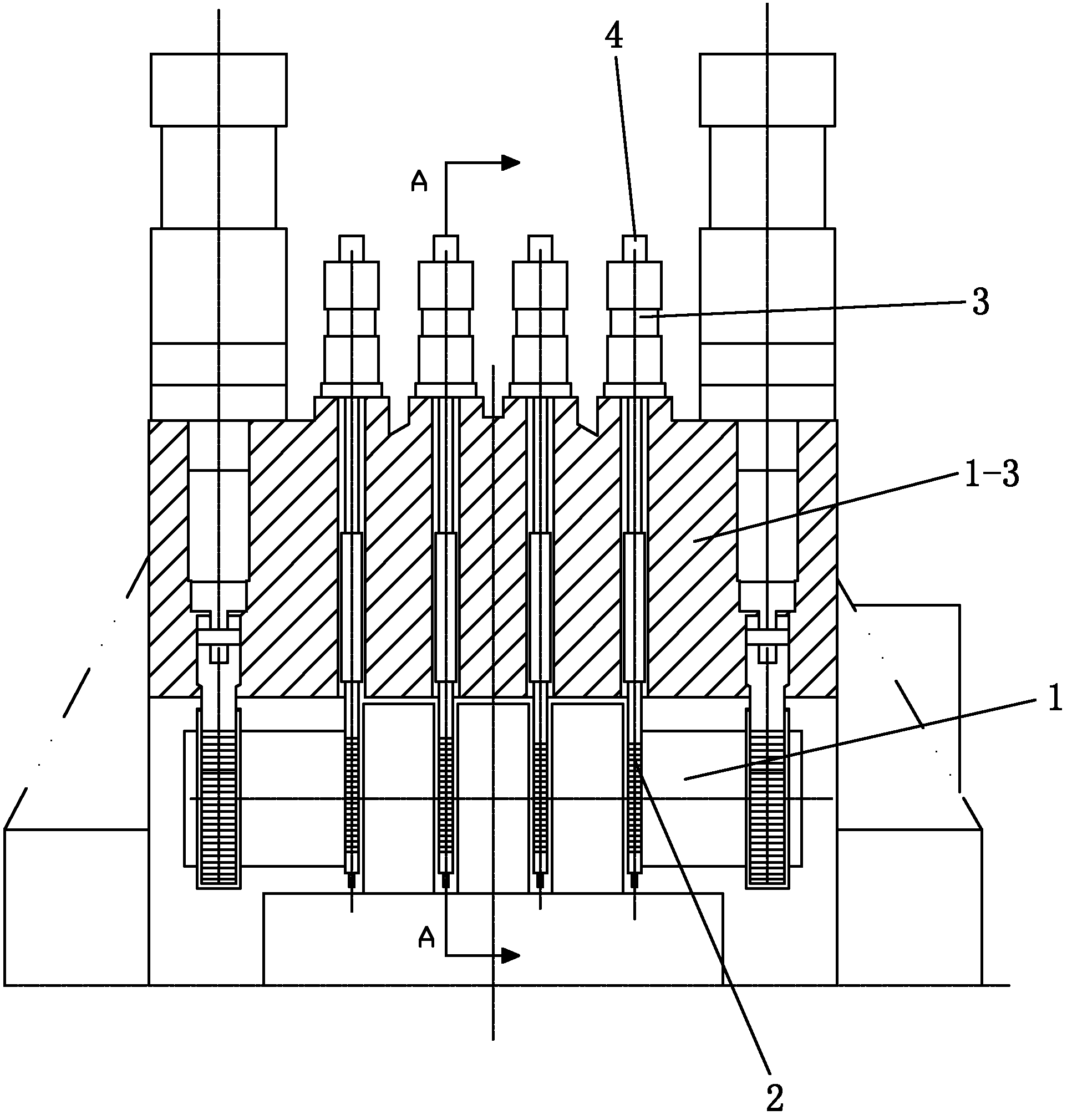

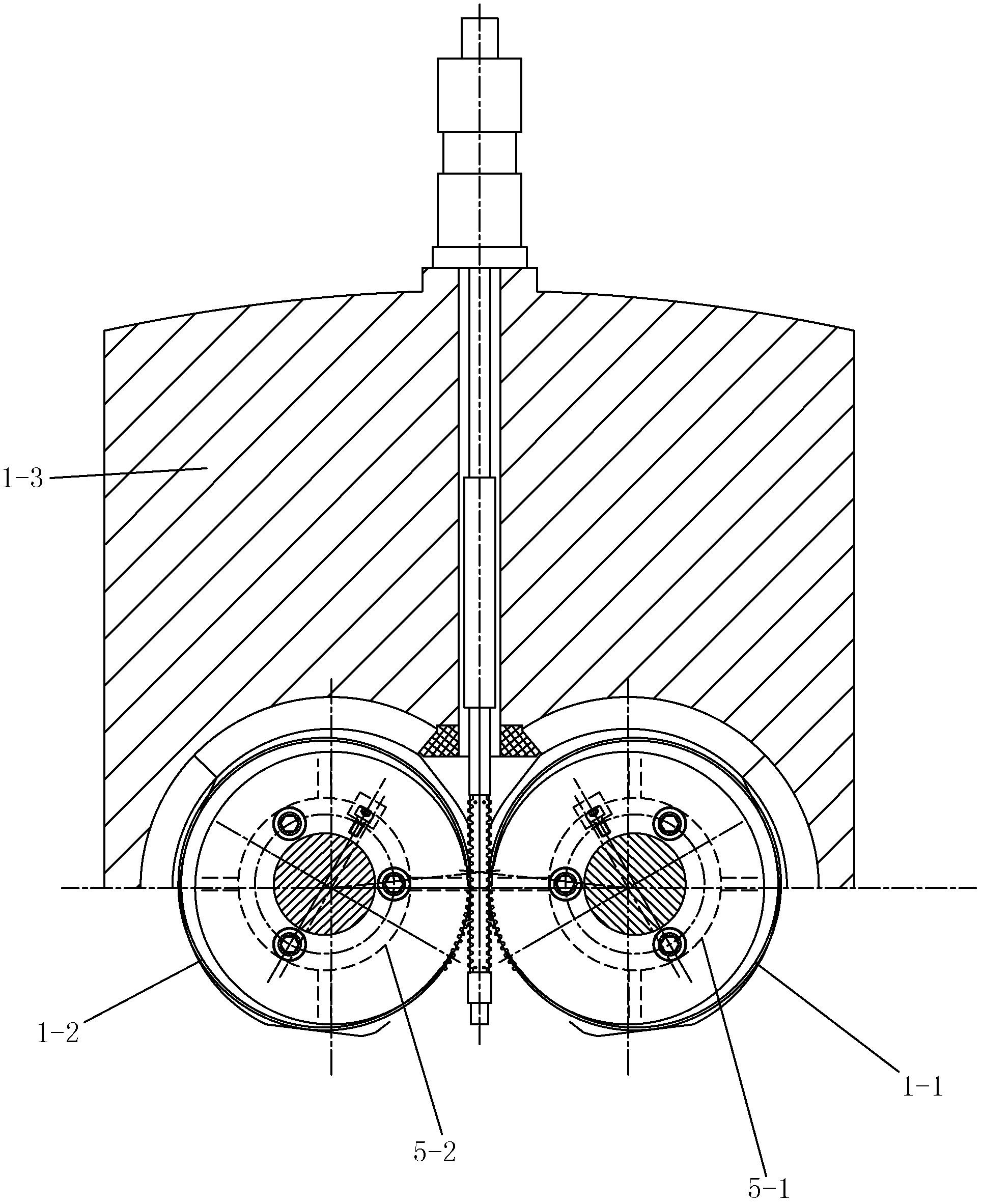

[0016] Such as figure 1 with figure 2 As shown, the present invention includes a backing roller assembly 1, a deviation adjustment rack 2 and a hydraulic cylinder 3 with a displacement sensor 4, and the backing roller assembly 1 includes a frame 1-3, a first roller 5-1, a second The roller 5-2, the first convexity deviation adjustment gear 1-1 and the second convexity deviation adjustment gear 1-2, the first roller 5-1 and the second roller 5-2 are arranged oppositely and are installed on the frame 1-3, the first convexity deviation adjustment gear 1-1 is installed on the first roller 5-1, and the second convexity deviation adjustment gear 1-2 is installed on the second roller 5-2, so The first convex deviation adjustment gear 1-1 and the second convex deviation adjustment gear 1-2 are arranged oppositely; the hydraulic cylinder 3 is installed on the frame 1-3, and the deviation adjustment rack 2 is installed on the hydraulic cylinder 3 and is meshed with the first convex d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com