Heavy-load walking beam lifting hydraulic control device

A control device and hydraulic technology, applied in the field of hydraulic control, can solve the problems of large power loss, complicated and complicated pipeline layout, etc., and achieve the effect of low power and simplified circuit and pipeline layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

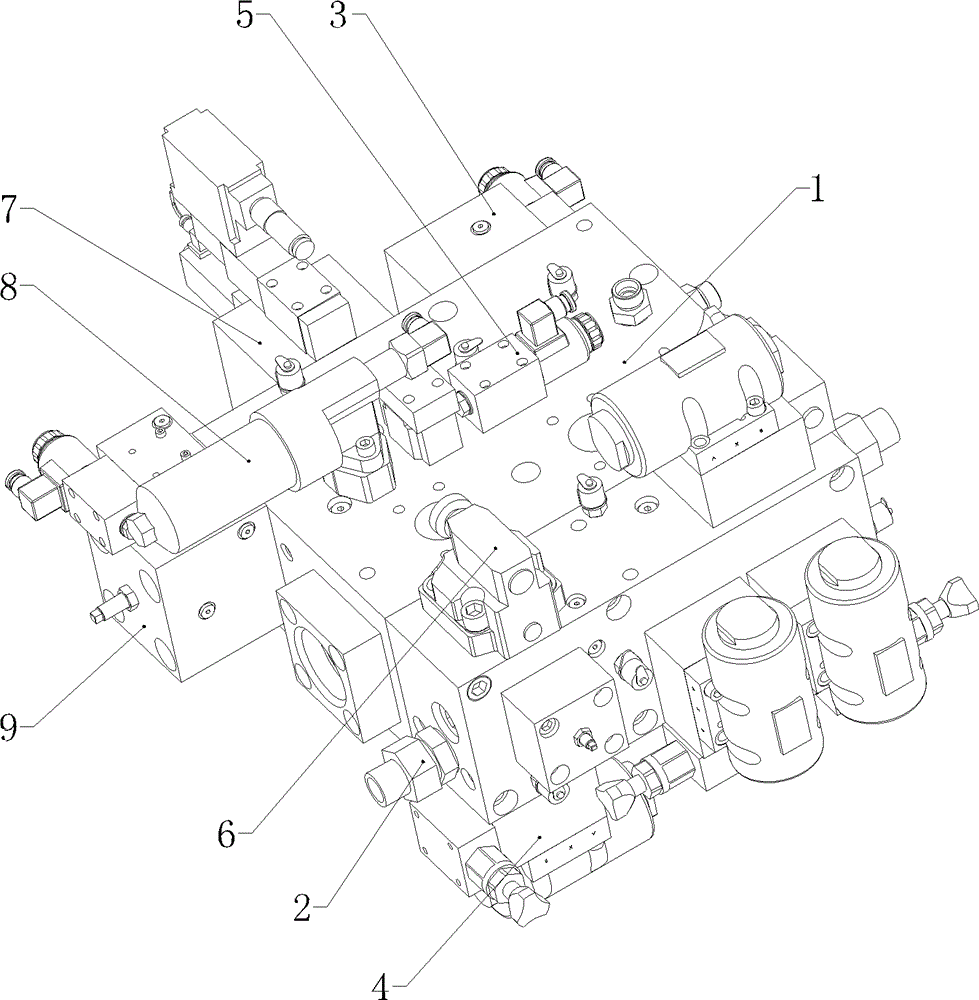

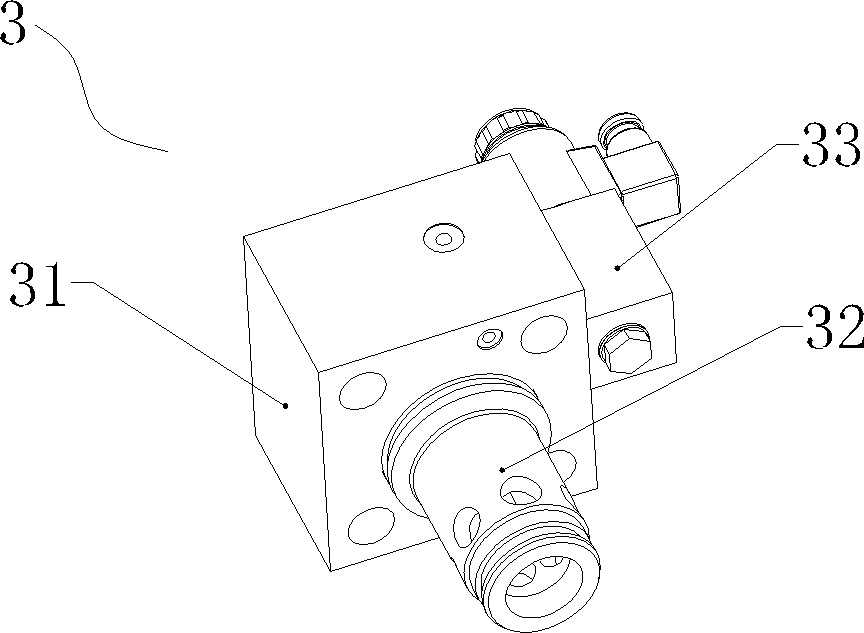

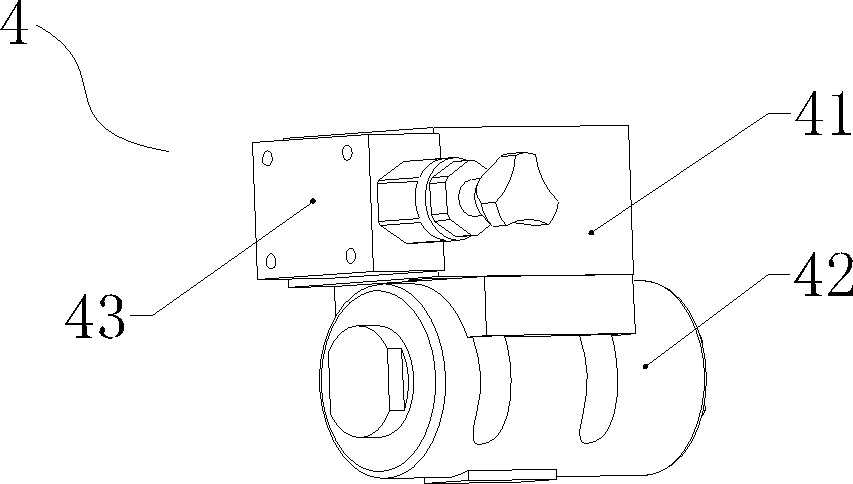

[0018] Such as Figure 1 to Figure 4 As shown, the heavy-duty moving beam lifting hydraulic control device of the present invention is mainly composed of several single-acting hydraulic cylinders (not shown in the figure) and an oil circuit block 1 . A number of hydraulic components are installed on the oil block 1, and these hydraulic components are mainly composed of a number of detachable high-pressure welded steel pipe joints 2, an oil inlet control unit 3, a number of safety locking units 4, an electromagnetic reversing valve 5, a safety valve 6, It consists of a high-response dynamic proportional cartridge valve 7, a precision high-pressure filter 8 and a dynamic oil return control unit 9. The piston rod ends of the several single-acting hydraulic cylinders are connected with the moving beam of the metal extruding machine to drive the moving beam for vertical lifting. The oil circuit of each single-acting hydraulic cylinder is connected with a detachable high-pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com