Integrated circuit (IC) line welding machine

A welding machine and circuit technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as narrow applicability, easy failure, and danger to workers, and achieve the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

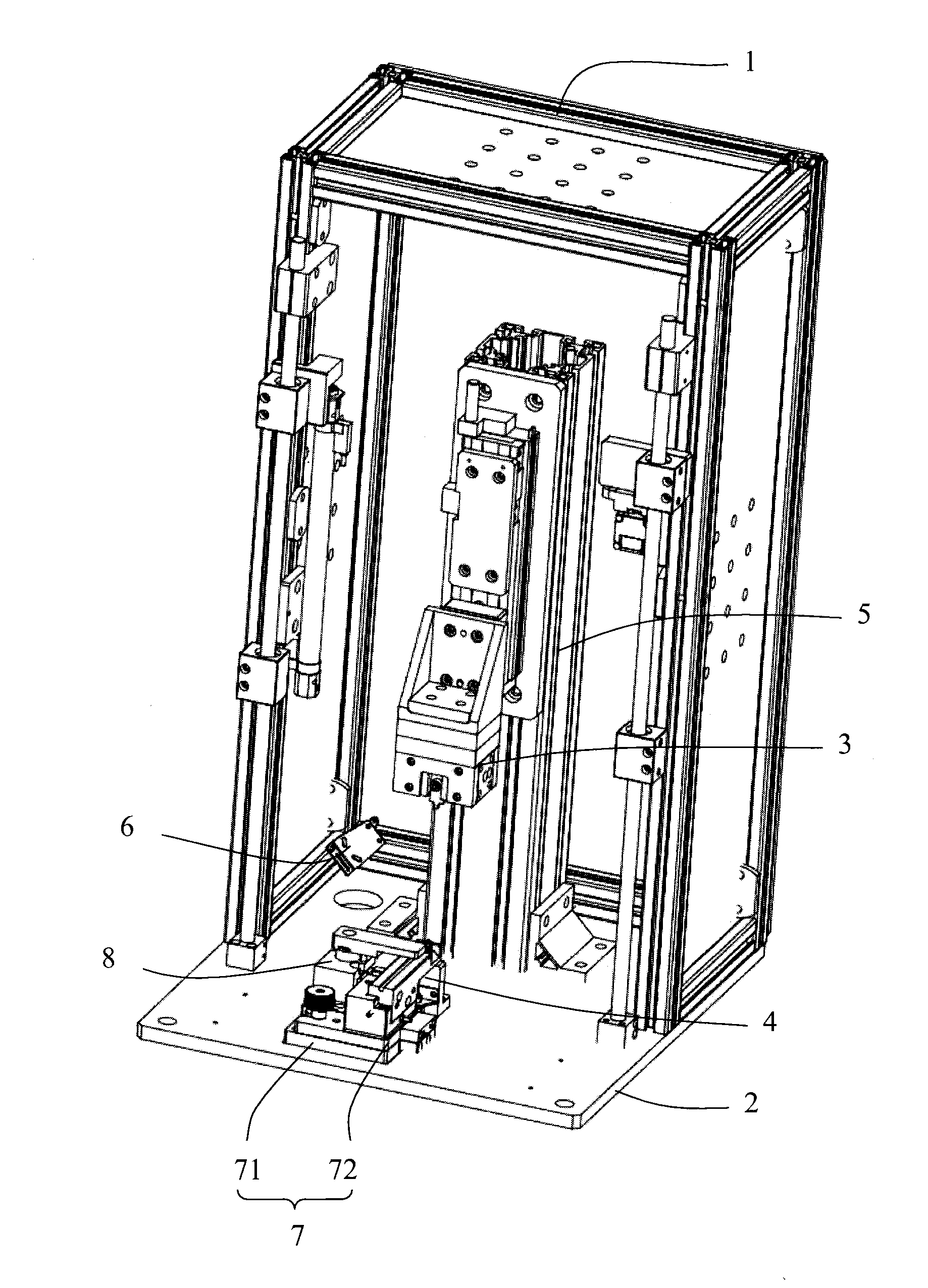

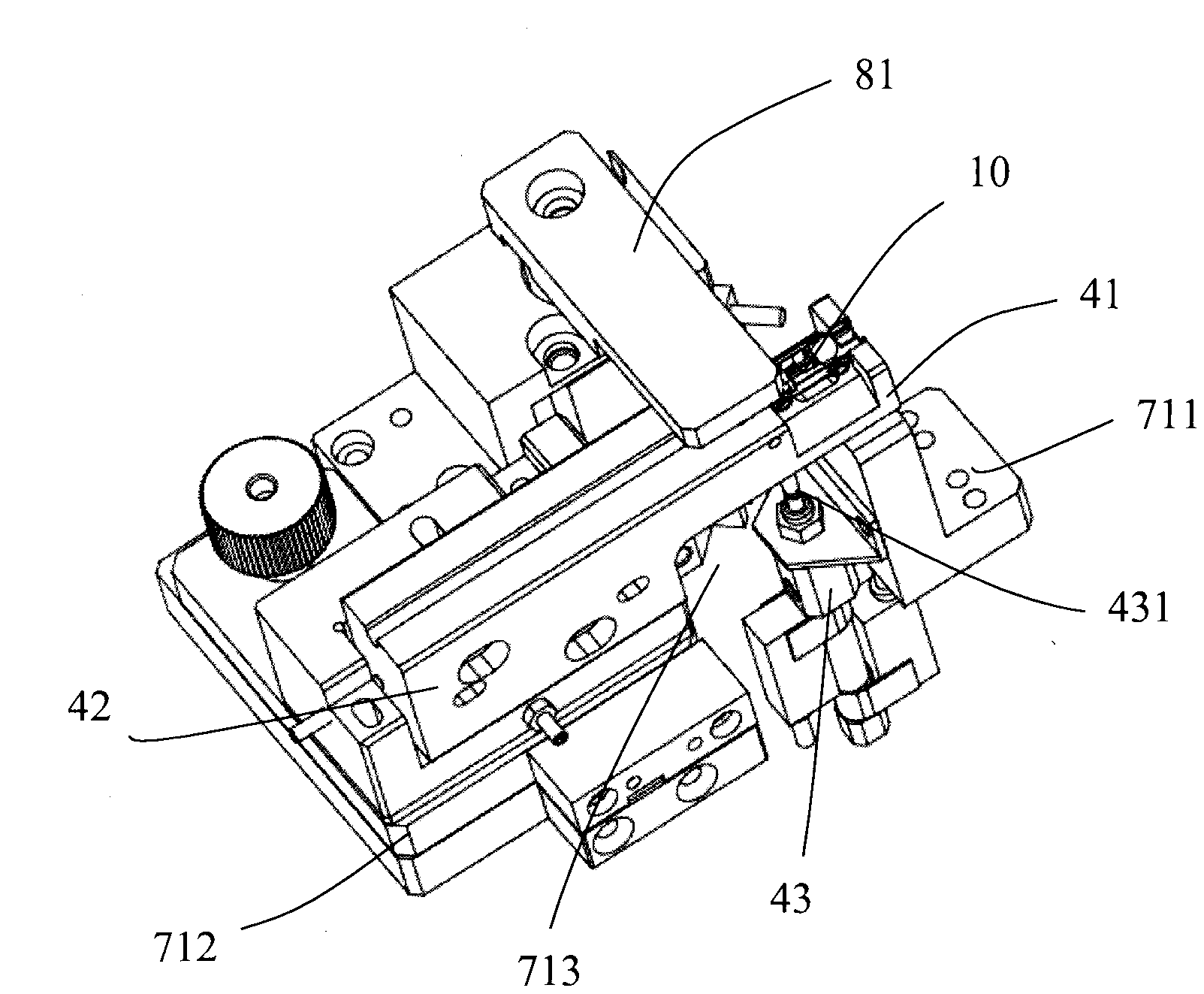

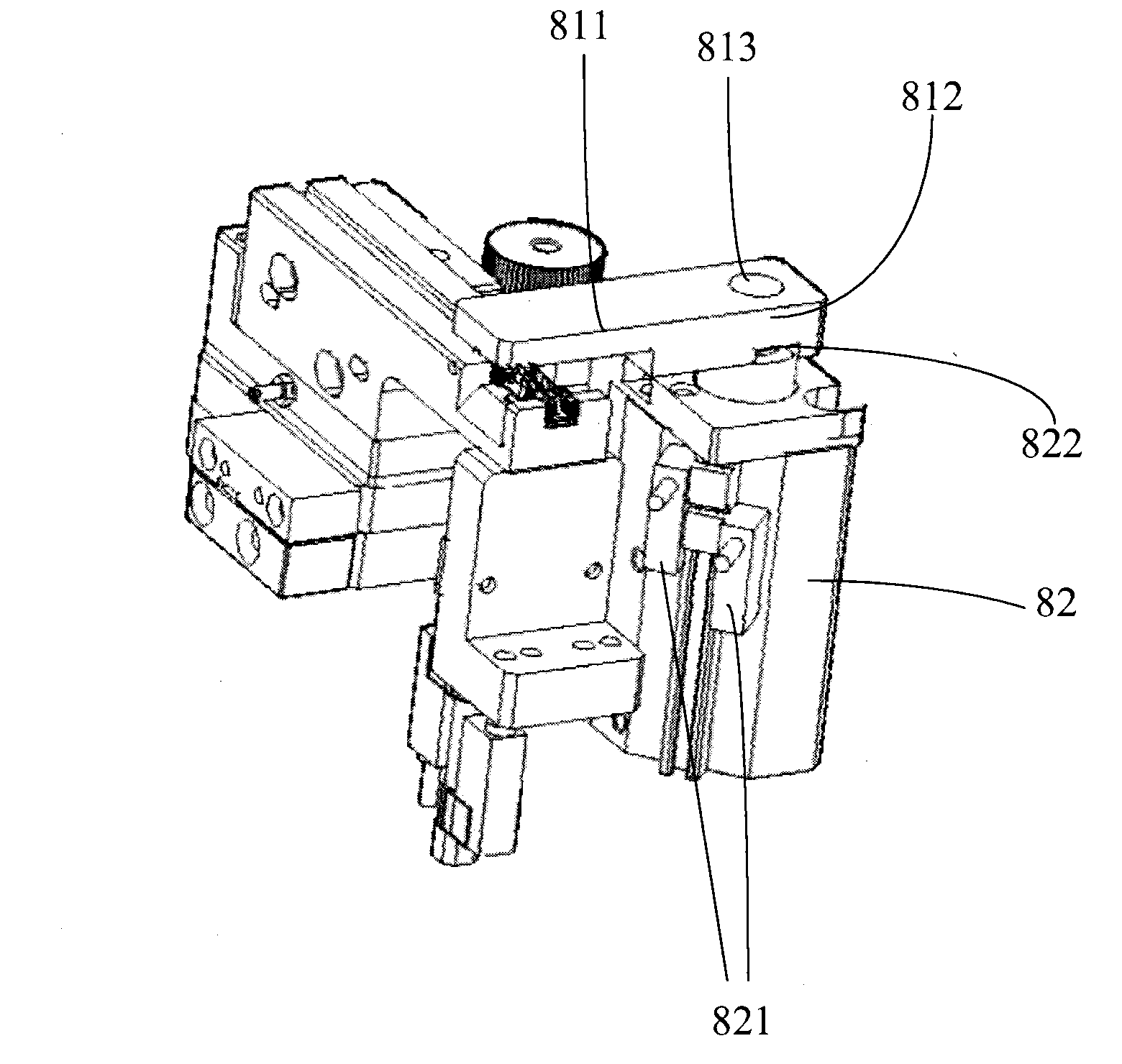

[0022] See figure 1 An IC circuit welding machine includes a bracket 1, a base 2 arranged in the bracket 1, a welding piece clamping device 4 and a welding piece clamping device 8 fixed on the base 2, and a welding piece above the welding piece clamping device 4. The head heating device 3 , the rail device 5 that drives the welding head heating device 3 to move up and down, and the observation piece 6 . The weldment clamping device 4 is used to clamp the weldment 10, while the weldment clamping device 8 is used to compress the weldment 10, so as to ensure that the weldment 10 will not pop out from the weldment clamping device 4 during the welding process Or displacement, affect the welding effect and welding time, realize the purpose of smooth welding and ensure the welding quality, the welding head heating device 3 welds the welding piece 10 clamped on the welding piece holding device 4 through the welding head 31 arranged on it, so The observation piece 6 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com