Waste circuit board powder-based toughening type spraying-free color regeneration composite material and preparation method

A waste circuit board, color regeneration technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems affecting the application range of recycled composite materials, the decline of mechanical properties of waste materials, and the low surface adhesion. problem, to achieve good appearance effect, to solve the effect of difficult to handle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this embodiment includes a colored surface layer and a filling layer;

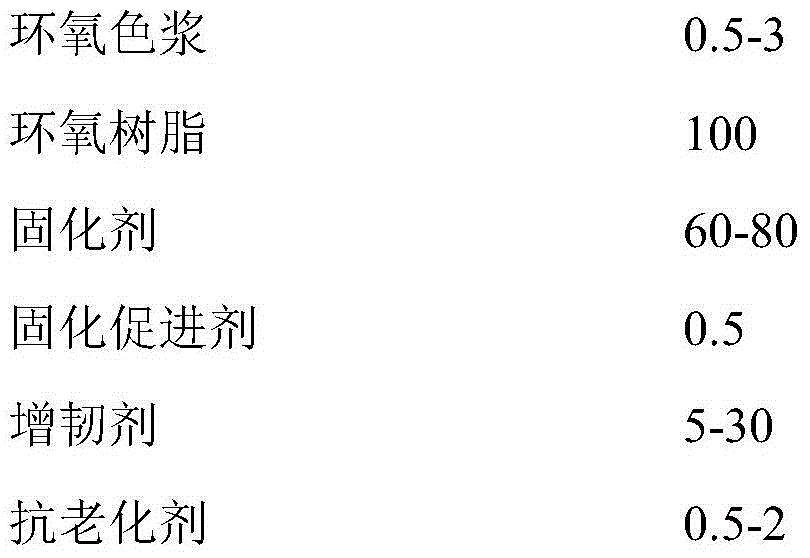

[0042] 1) The colored surface layer is mainly made of the following raw materials in parts by weight:

[0043] Epoxy Color Paste 1

[0044] epoxy resin 100

[0045] Hardener 60

[0046] Curing Accelerator 0.5

[0047] Toughener 20

[0048] anti aging agent 2

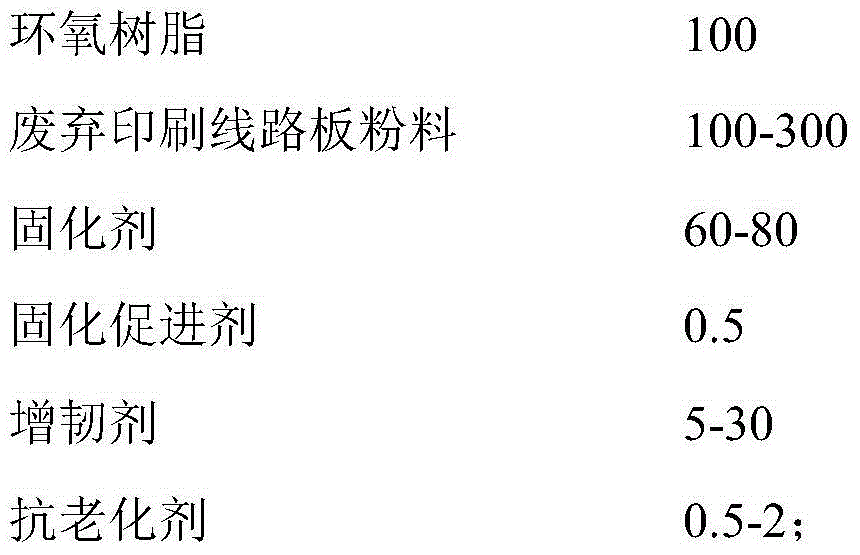

[0049] 2) The filling layer is mainly made of the following raw materials in parts by weight:

[0050] epoxy resin 100

[0051]Waste printed circuit board powder 200

[0052] Hardener 60

[0053] Curing Accelerator 0.5

[0054] Toughener 20

[0055] anti aging agent 2

[0056] The epoxy resin is bisphenol A general-purpose epoxy resin E-51.

[0057] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this example is prepared by the following method:

[0058] (1) Preparation...

Embodiment 2

[0072] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this embodiment includes a colored surface layer and a filling layer;

[0073] 1) The colored surface layer is mainly made of the following raw materials in parts by weight:

[0074] Epoxy Color Paste 3

[0075] epoxy resin 100

[0076] Hardener 80

[0077] Curing Accelerator 0.5

[0078] Toughener 30

[0079] anti aging agent 2

[0080] 2) The filling layer is mainly made of the following raw materials in parts by weight:

[0081] epoxy resin 100

[0082] Waste printed circuit board powder 300

[0083] Hardener 80

[0084] Curing Accelerator 0.5

[0085] Toughener 25

[0086] anti aging agent 1

[0087] Wherein the epoxy resin is bisphenol A general-purpose epoxy resin E-51.

[0088] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this example is prepared by the following method:

[0089] (1) Pr...

Embodiment 3

[0096] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this embodiment includes a colored surface layer and a filling layer;

[0097] 1) The colored surface layer is mainly made of the following raw materials in parts by weight:

[0098] Epoxy color paste 0.5

[0099] epoxy resin 100

[0100] Hardener 60

[0101] Curing Accelerator 0.5

[0102] Toughener 20

[0103] anti aging agent 2

[0104] 2) The filling layer is mainly made of the following raw materials in parts by weight:

[0105] epoxy resin 100

[0106] Waste printed circuit board powder 100

[0107] Hardener 60

[0108] Curing Accelerator 0.5

[0109] Toughener 5

[0110] Anti-aging agent 0.5

[0111] Wherein the epoxy resin is bisphenol A general-purpose epoxy resin E44.

[0112] The waste circuit board powder-based toughened spray-free colored recycled composite material provided in this example is prepared by the following method:

[0113] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com