Large treatment capacity reactor for degrading wastewater of finely-intercepted nano photocatalyst

A nano-photocatalyst and wastewater degradation technology, which can be used in illumination water/sewage treatment, oxidized water/sewage treatment, etc., and can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

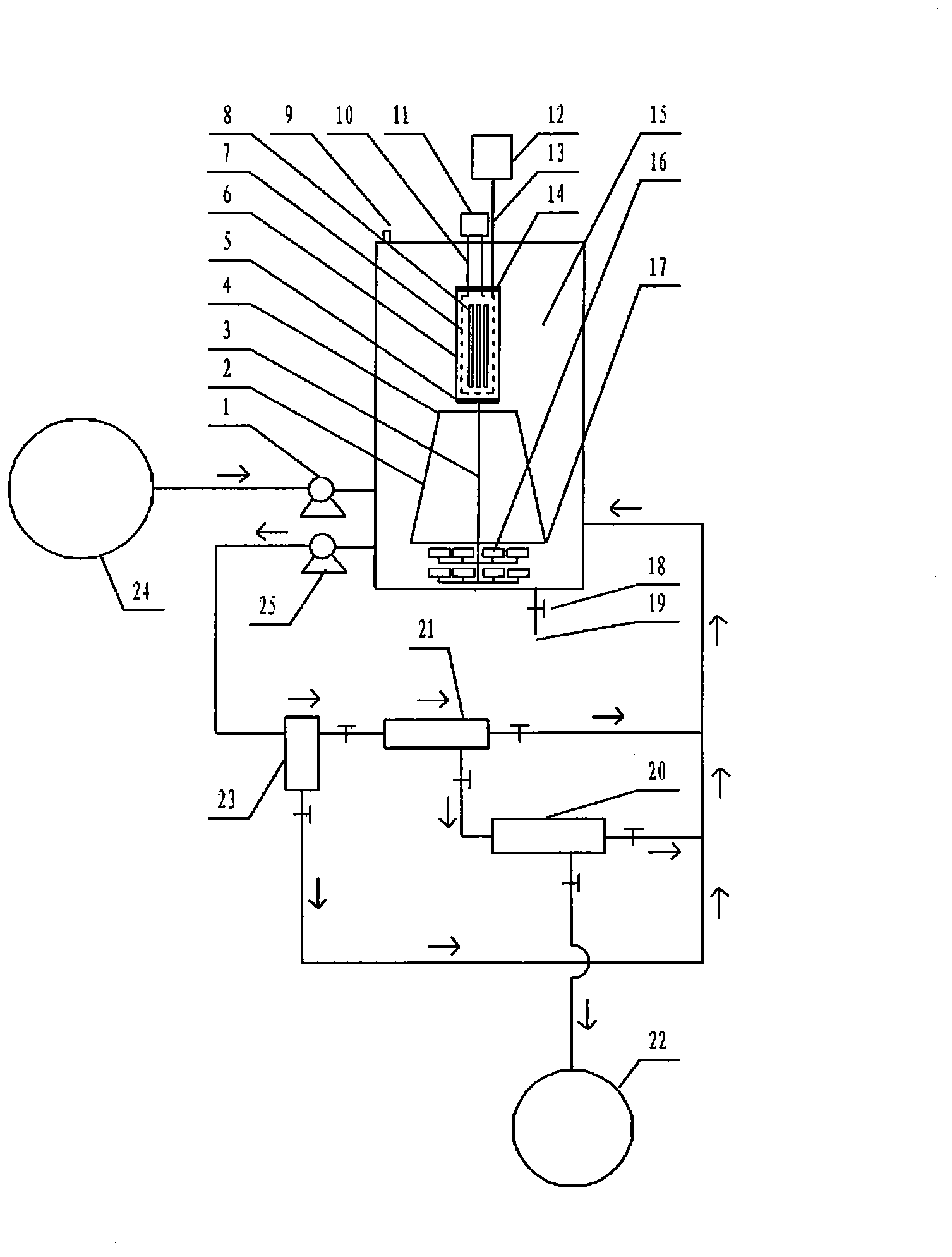

[0068] exist figure 1 In the shown embodiment of the case, the structure of the reactor includes a container, and the outline of the container is in the shape of a cube, a cuboid, a cylinder, an ellipse, a polygon, a sphere or an ellipsoid. The bottom position of the inner cavity of the container is equipped with many microporous aeration heads 16, and the quartz tube 6 is installed on the inner cavity position of the container, and the two ends of the quartz tube 6 are equipped with seals. The plugging caps 5 and 14 are respectively provided with ventilation ports on the plugging caps 5 and 14 located at both ends of the quartz tube 6, and the electrodeless ultraviolet lamp 8 is rod-shaped, ring-shaped, spherical, or starfish-shaped. or sea urchin shape, the number of the electrodeless ultraviolet lamp 8 is at least one, and the number of the electrodeless ultraviolet lamp 8 is at least one above the inside of the quartz tube 6, and the air pump 12, the air pump 12 is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com