Sealing connection method of high borosilicate glass tube and copper

A high borosilicate glass and copper sealing technology, which is applied in the field of glass and metal sealing in the solar energy industry, can solve the problems of inability to achieve high borosilicate glass sealing and high melting point of copper, so as to facilitate automatic production, improve temperature resistance, and technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

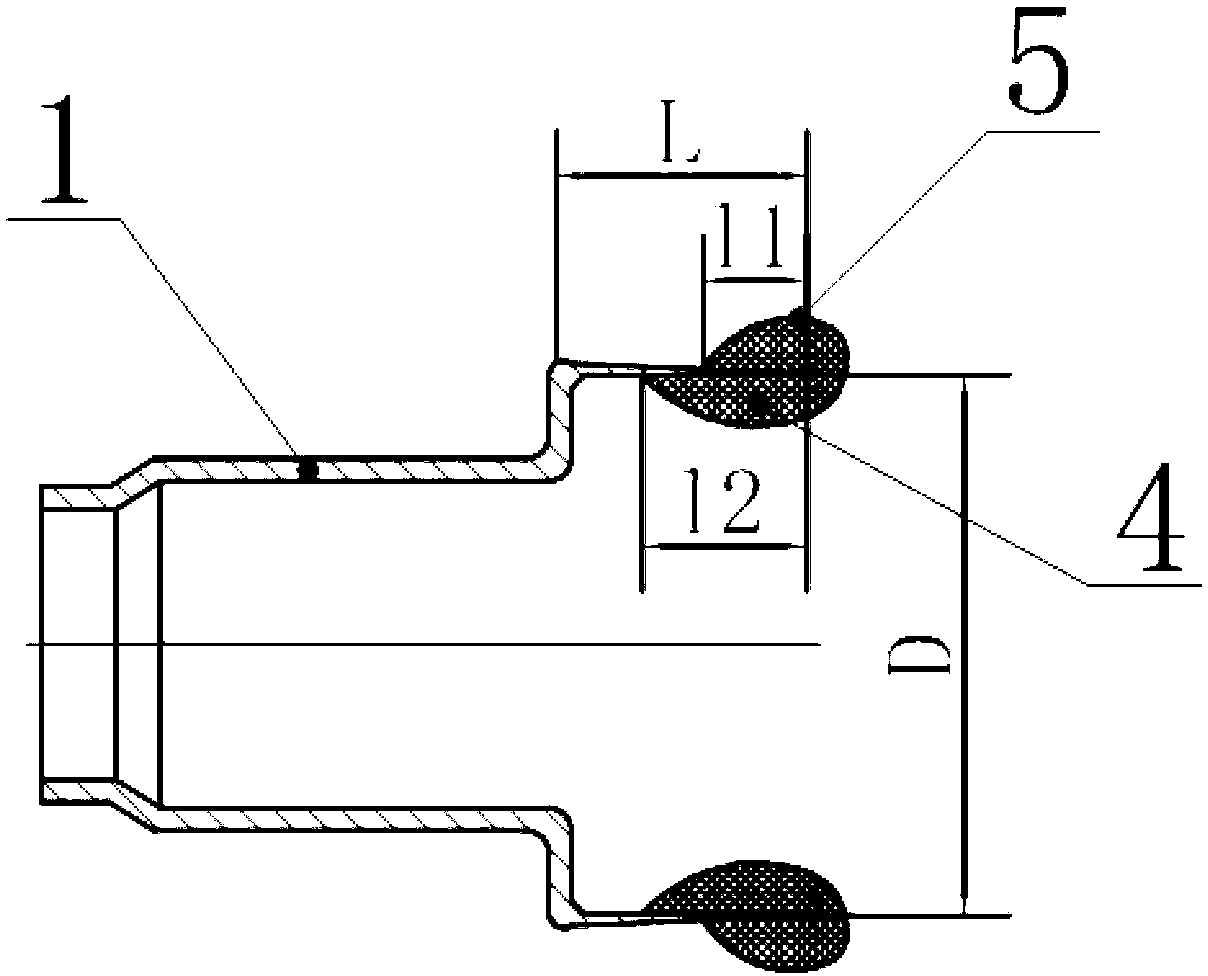

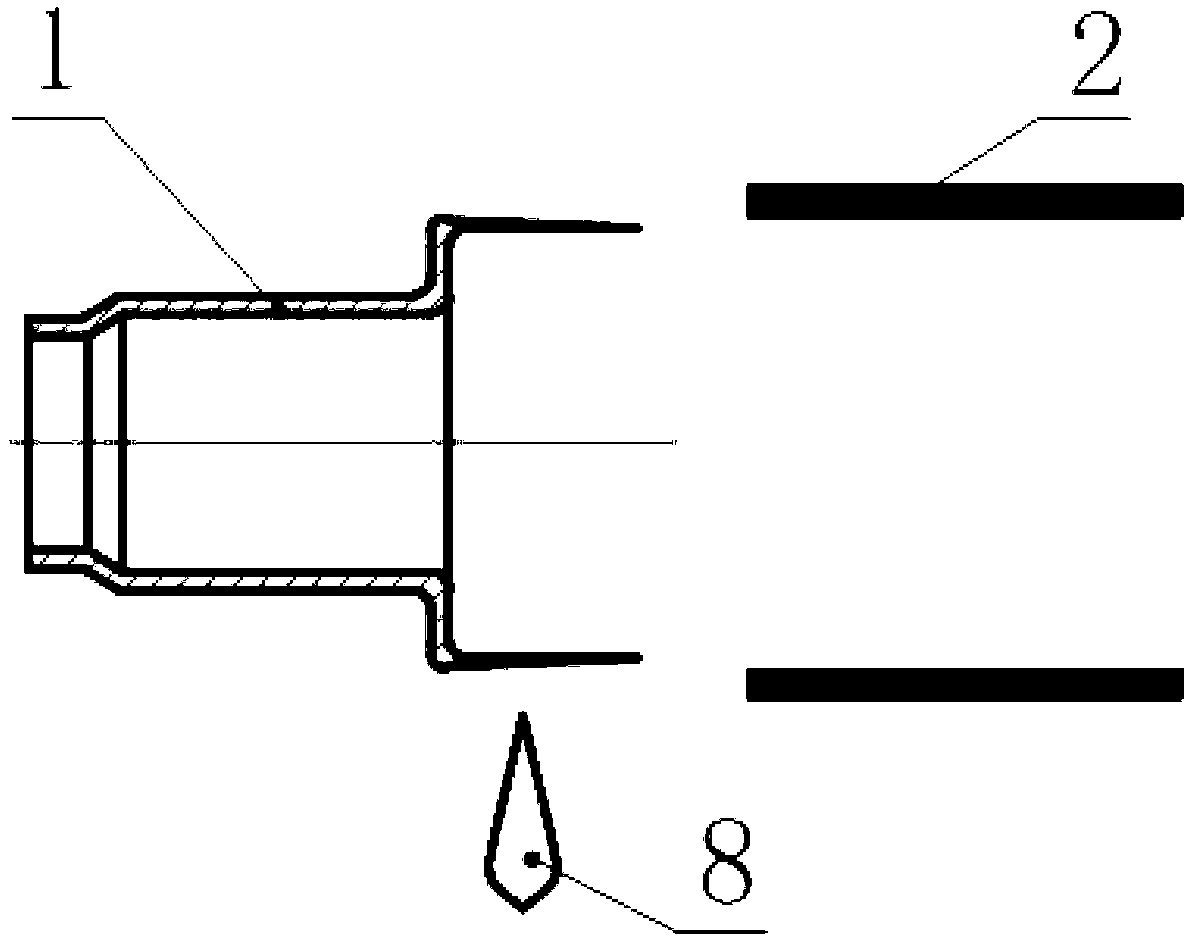

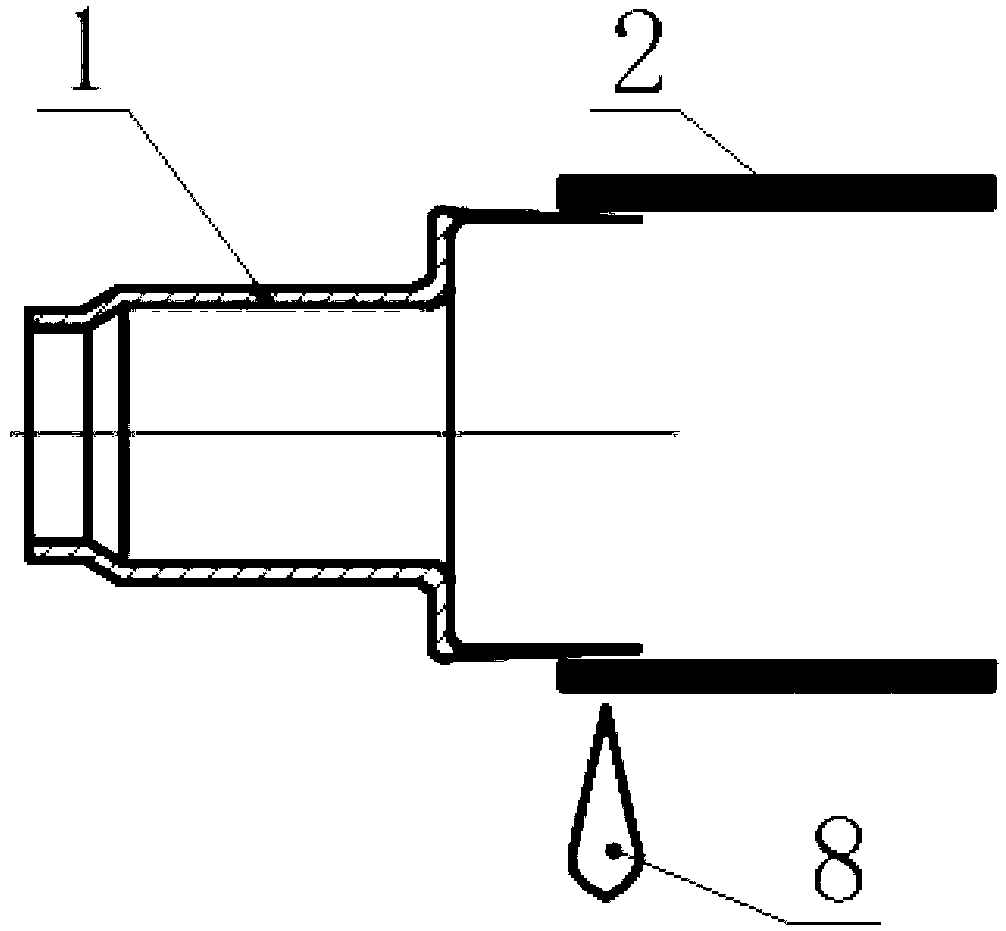

[0022] Such as figure 1 The diameter D of the copper sealing part 1 shown is 25mm, and the diameter L is 15mm, such as image 3 The shown borosilicate glass tube 2 has a wall thickness of 1.5mm and an inner diameter of 28mm. The material of the copper sealing part 1 is high-purity oxygen-free copper, wherein O≤0.003%, P≤0.0005%, As≤0.002%; the edge thickness of the copper sealing part 1 is 0.04mm-0.06mm, and the slope of the knife edge is 2°-3°30'.

[0023] The method for sealing the high borosilicate glass tube 2 and the copper sealing member 1 comprises the following steps:

[0024] a) Clean the copper sealing part 1 to remove impurities such as oil stains and oxides on the surface, and then perform high-temperature heat treatment on the copper sealing part 1. The temperature is set at 600°C-650°C, and the holding time is 2-5min. Effectively relieve stress and at the same time play the role of exhaust.

[0025] b) The borosilicate glass tube 2 is ultrasonically cleaned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com