Single-well coalbed methane horizontal well system and finishing method thereof

A technology for horizontal wells and coalbed methane, which is applied in wellbore/well components, earthwork drilling, and fluid production, etc., can solve problems such as waste of resources, increase drilling costs, and increase floor space, so as to avoid waste of resources and reduce wells. Effects of site footprint and drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

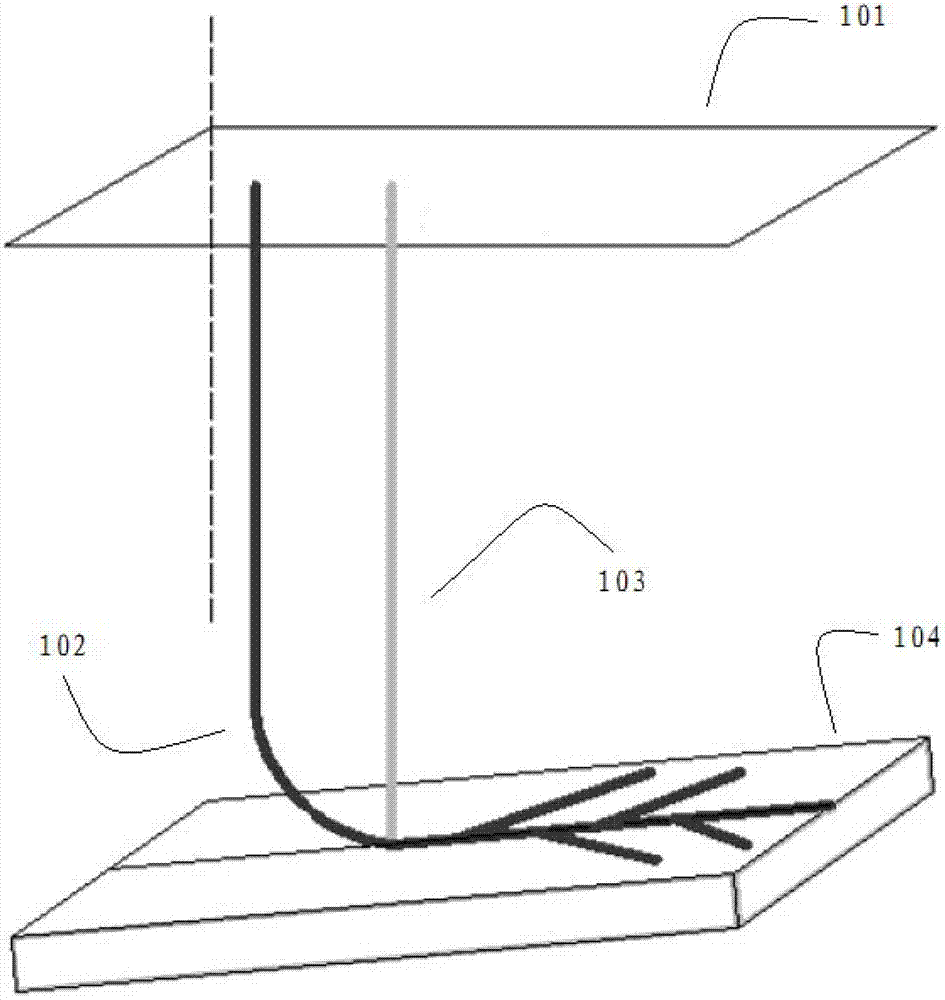

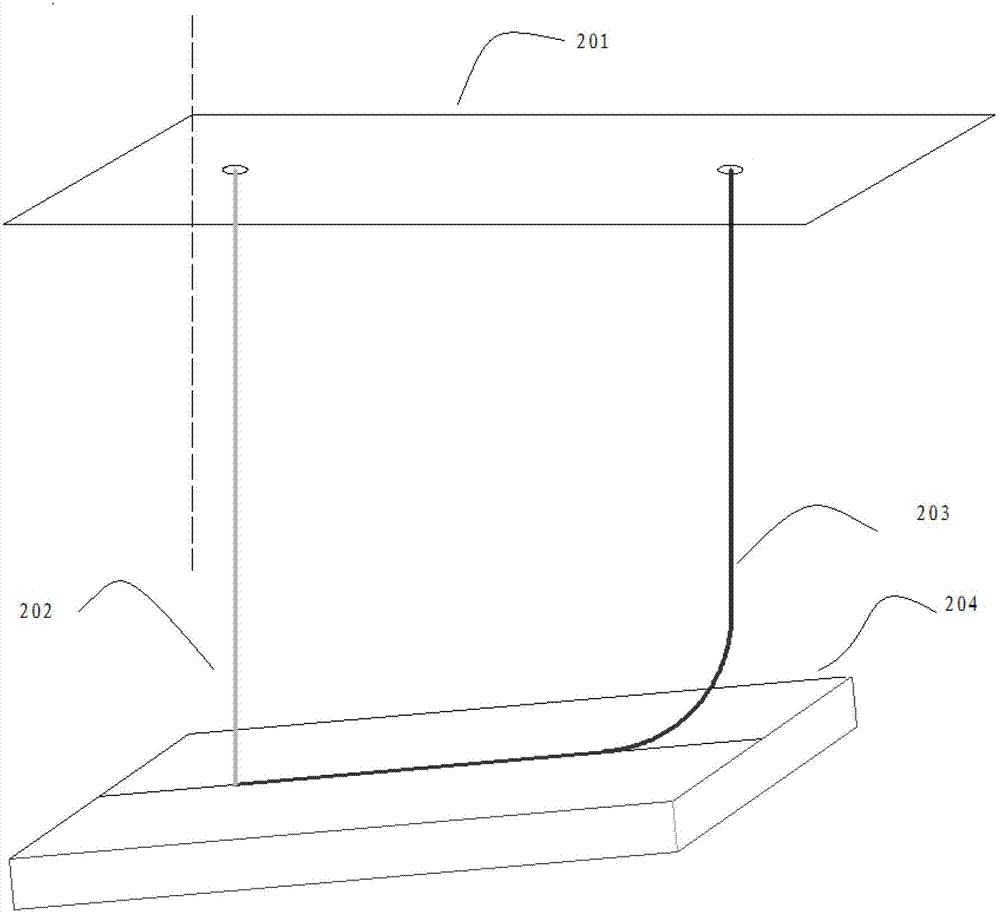

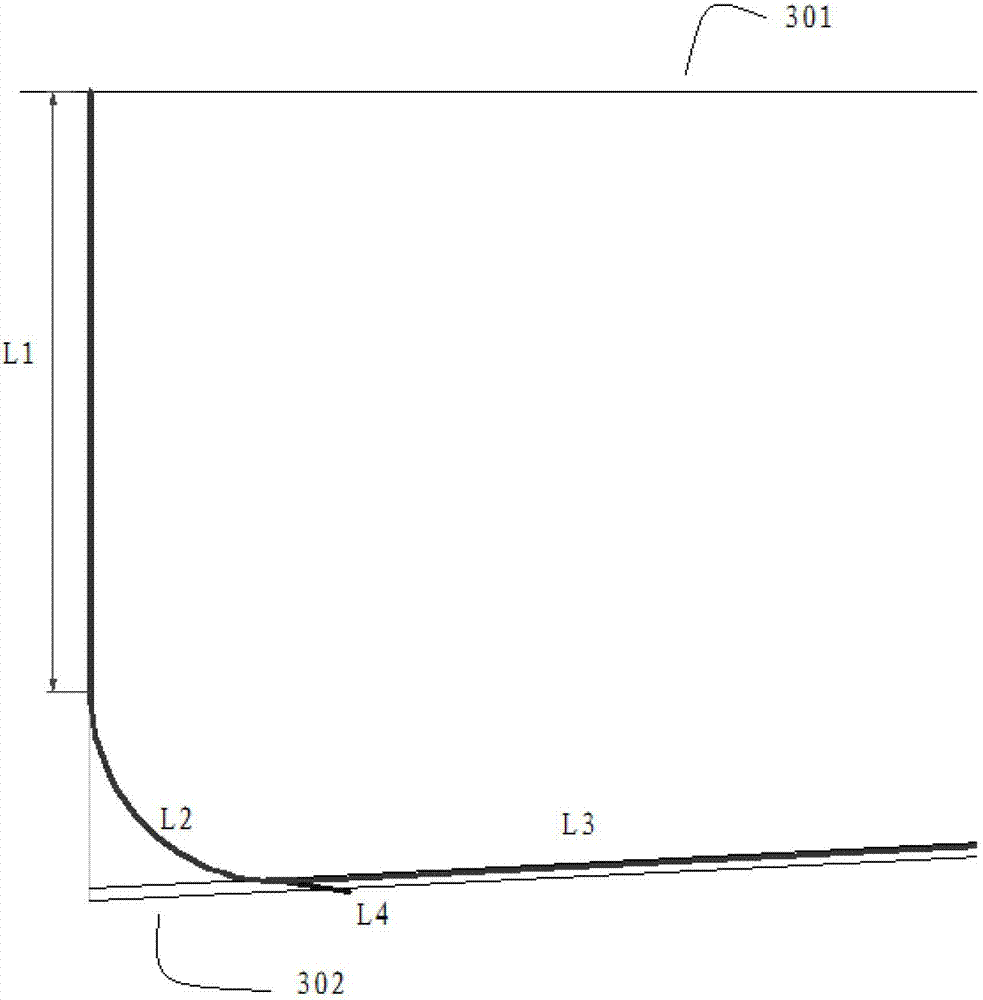

[0025] The core idea of the present invention is to develop coalbed methane by using a single borehole horizontal well system, and the specific technical solution is to complete a horizontal wellbore, and use the borehole to provide drainage channels for coal seams and desorption channels for coalbed methane. Then sidedrill the branch pockets in the horizontal wellbore, and use the branch pockets to realize the function of collecting the pulverized coal produced in the coal seam in the production vertical well in the prior art, while the drainage in the production vertical wells in the prior art The equipment was lowered in a horizontal well instead. Thereby realized the function of two wells of prior art with one well.

[0026] i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com