Comb-shaped tongue piece shunting variable cross-section turbine pressurizer

A turbocharger and variable cross-section technology, which is applied to machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of high exhaust gas temperature, high and difficult material requirements for variable cross-section turbochargers, and is simple to meet technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

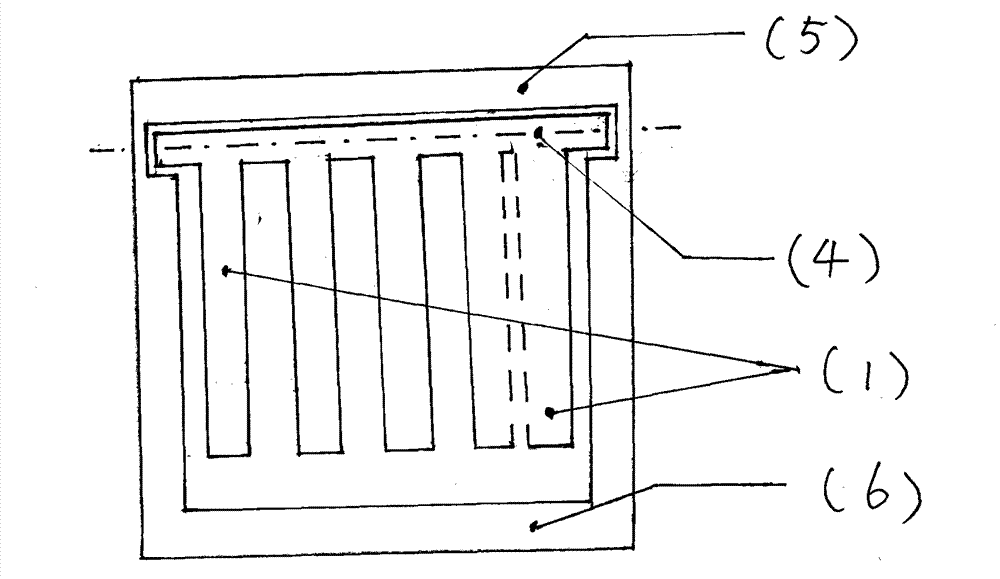

[0010] figure 1 Among them, the ratio of the comb-shaped tongue (1) tooth to the cross-sectional area of the rotating shaft (4) and the flow cross-sectional area of the vortex tube at the split point (10) is K, and K=181 / 432; the comb-shaped tongue (1) tooth The ratio of the total mass (grams) to the sum of the cross-sectional area of the gear shaft (mm2) is N, and N=(11 / 1086); the flow section (10) of the split point vortex tube is a square, and its side length is a, and the comb-shaped tongue (1) The tooth is a hollow cylindrical tooth, and the tooth length is set to b, b / a=8 / 9.

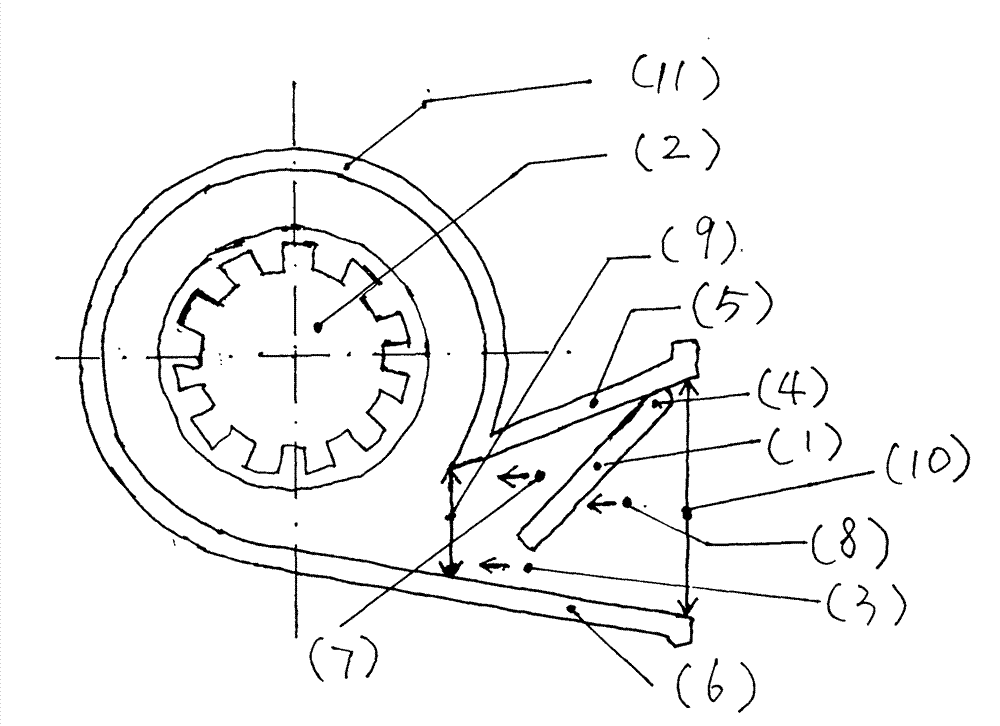

[0011] figure 2 In the vehicle-mounted installation, the central axis of the rotating shaft (4) is perpendicular to the wheel axis, the exhaust direction on the lower side of the scroll tube (6) is at an angle of 15 degrees to the plane of the four-wheel axis of the car, and the upper side of the scroll tube (5) is connected to the lower side of the scroll tube. The side (6) is symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com