Super absorbent sheet composite material, and preparation method and application thereof

A highly absorbent, composite material technology, used in non-adhesive dressings, dressings, absorbent pads, etc., can solve problems such as discomfort, airtightness, large space and usage, and achieve improved water retention and water retention, thickness reduction, Guaranteed stability and spillover effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

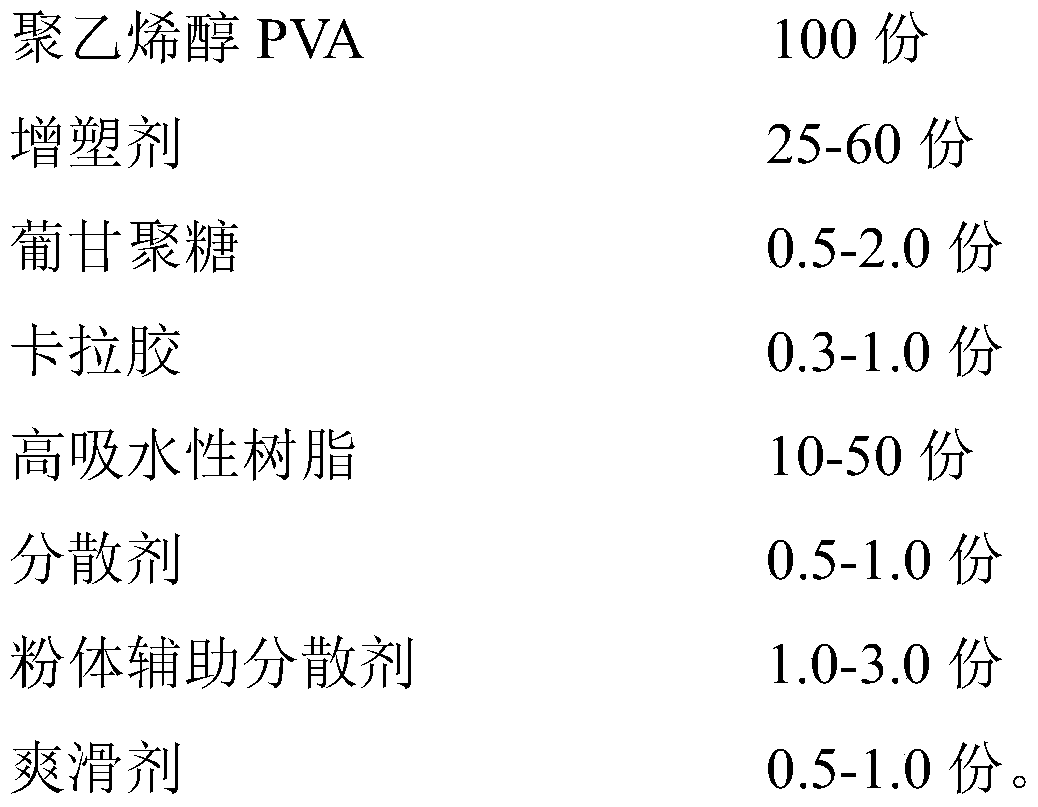

[0053] A superabsorbent sheet composite material, in parts by weight, comprising the following components:

[0054]

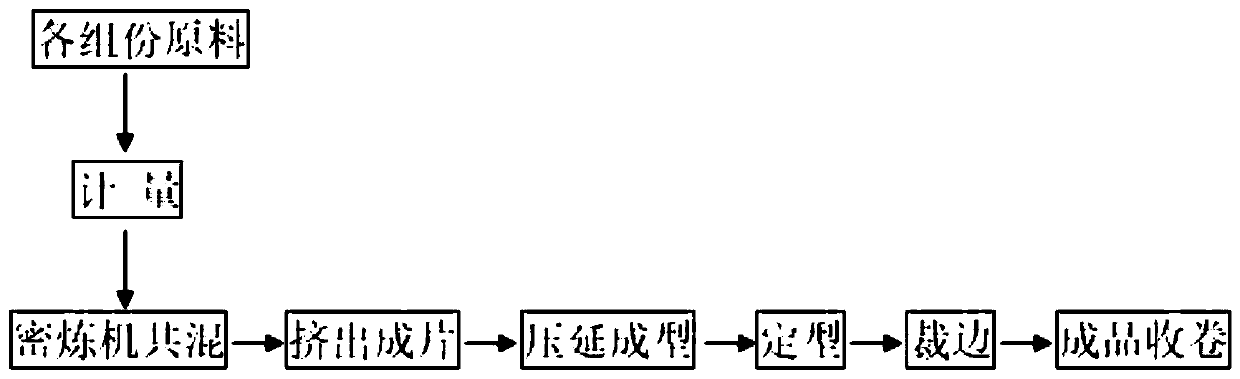

[0055] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 120°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0056] The prepared calendered composite sheet has a thickness of 85 μm.

[0057] The technical specifications of the superabsorbent sheet composite material prepared in Example 1 are shown in Table 1.

[0058] Table 1

[0059]

[0060] It can be seen from the above test data that the superabsorbent sheet composite material prepared in Example 1 not only has a higher absorbing ratio of physiological saline, but is particularly outstanding in maintaining the ratio of physiological saline.

Embodiment 2

[0062] A superabsorbent sheet composite material, in parts by weight, comprising the following components:

[0063]

[0064] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 160°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0065] The prepared calendered composite sheet has a thickness of 500 μm.

[0066] The technical specifications of the superabsorbent sheet composite material prepared in Example 2 are shown in Table 2.

[0067] Table 2

[0068]

[0069] From the above test data, it can be seen that the superabsorbent sheet composite material prepared in Example 2 not only has a higher absorption rate of physiological saline, but is particularly outstanding in maintaining the rate of physiological saline.

Embodiment 3

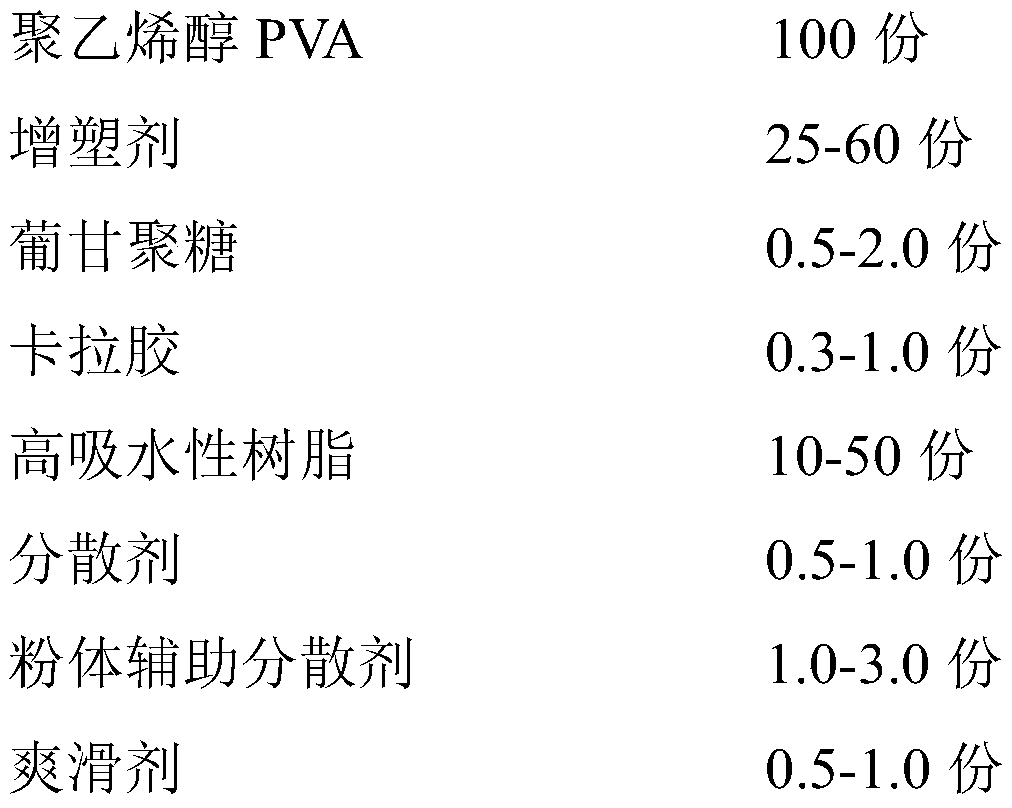

[0071] A superabsorbent sheet composite material, in parts by weight, at least includes the following components:

[0072]

[0073] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 150°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0074] The prepared calendered composite sheet has a thickness of 300 μm.

[0075] The technical indicators of the superabsorbent sheet composite material prepared in Example 3 are shown in Table 3.

[0076] table 3

[0077]

[0078]

[0079] From the above test data, it can be seen that the superabsorbent thin film composite material prepared in Example 3 not only has a higher absorption rate of physiological saline, but is particularly outstanding in maintaining the rate of physiological saline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com