A kind of superabsorbent sheet composite material and its preparation method and application

A composite material, high water absorption technology, used in non-adhesive dressings, dressings, absorbent pads, etc., can solve the problems of airtightness, large space and usage, discomfort, etc., to improve water retention and water retention, and ensure stability. , the effect of thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

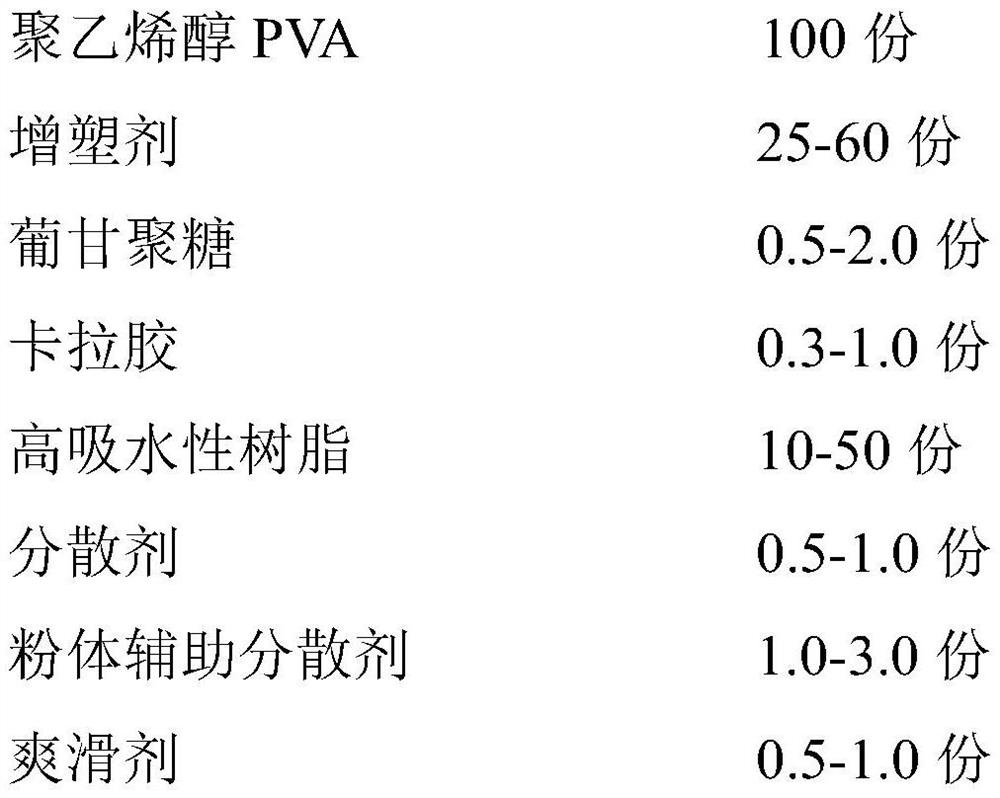

[0053] A superabsorbent sheet composite material, in parts by weight, comprising the following components:

[0054]

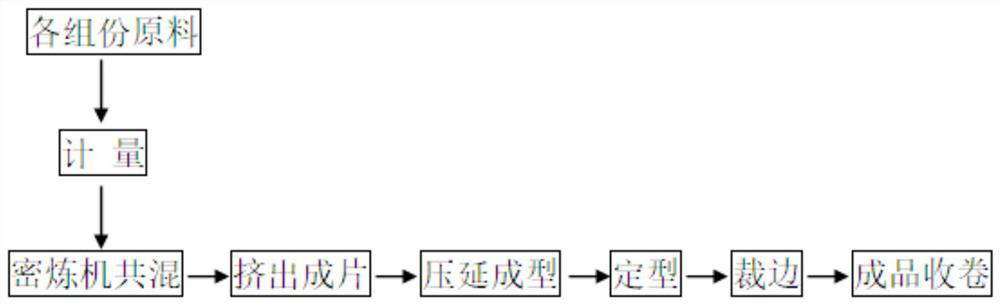

[0055] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 120°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0056] The prepared calendered composite sheet has a thickness of 85 μm.

[0057] The technical specifications of the superabsorbent sheet composite material prepared in Example 1 are shown in Table 1.

[0058] Table 1

[0059]

[0060] It can be seen from the above test data that the superabsorbent sheet composite material prepared in Example 1 not only has a higher absorbing ratio of physiological saline, but is particularly outstanding in maintaining the ratio of physiological saline.

Embodiment 2

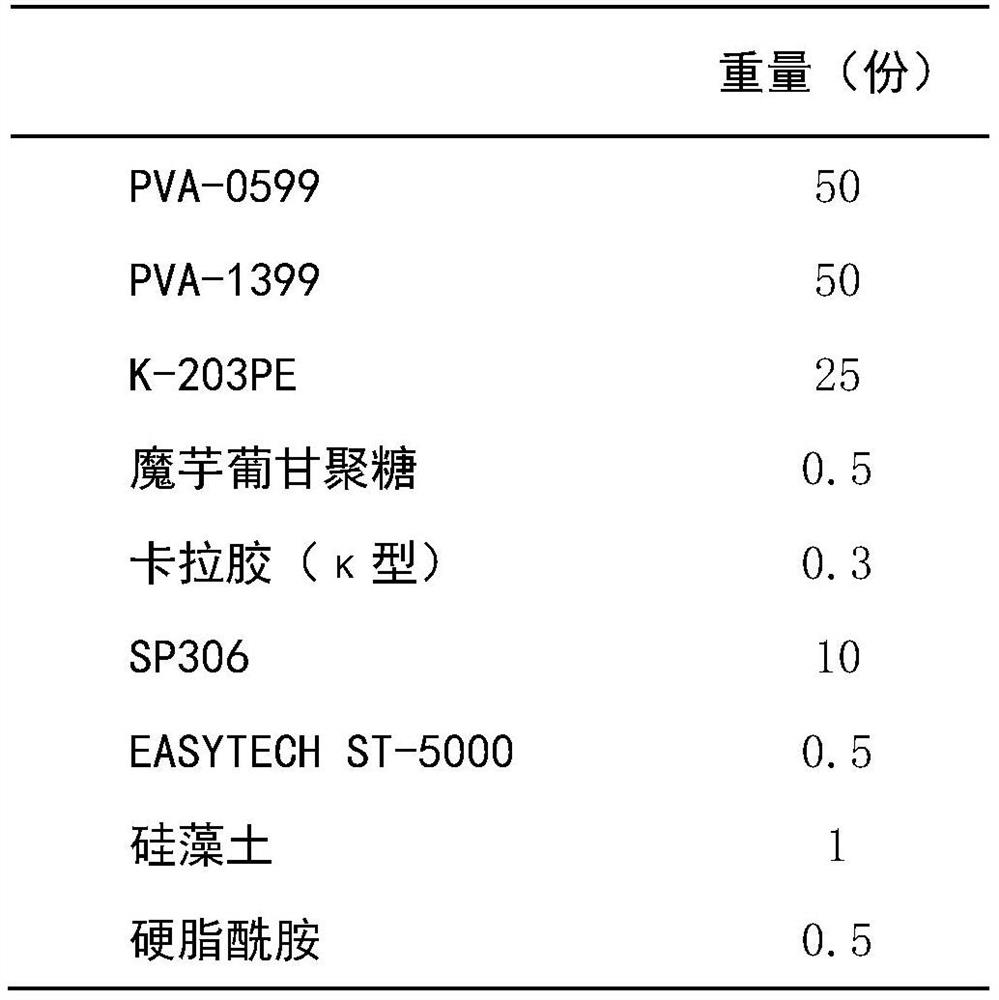

[0062] A superabsorbent sheet composite material, in parts by weight, comprising the following components:

[0063]

[0064] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 160°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0065] The prepared calendered composite sheet has a thickness of 500 μm.

[0066] The technical specifications of the superabsorbent sheet composite material prepared in Example 2 are shown in Table 2.

[0067] Table 2

[0068]

[0069] From the above test data, it can be seen that the superabsorbent sheet composite material prepared in Example 2 not only has a higher absorption rate of physiological saline, but is particularly outstanding in maintaining the rate of physiological saline.

Embodiment 3

[0071] A superabsorbent sheet composite material, in parts by weight, at least includes the following components:

[0072]

[0073] Its preparation process is as figure 1 As shown, the process conditions: the banburying temperature is 150°C; the temperature of the single-screw extruder is 6-zone temperature control: 100 / 120 / 140 / 160 / 160 / 150°C; the calendering triple roll temperature is: 140 / 150 / 130°C; the shaping temperature of the shaping roller is 25°C.

[0074] The prepared calendered composite sheet has a thickness of 300 μm.

[0075] The technical indicators of the superabsorbent sheet composite material prepared in Example 3 are shown in Table 3.

[0076] table 3

[0077]

[0078]

[0079] From the above test data, it can be seen that the superabsorbent thin film composite material prepared in Example 3 not only has a higher absorption rate of physiological saline, but is particularly outstanding in maintaining the rate of physiological saline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com