Autoclave inner cavity insulation device

A heat preservation device and autoclave technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of high temperature on the outer surface of the shell, increased thermal conductivity of heat insulation materials, and large heat loss on the outer surface of the shell, etc. problems, to achieve good oil resistance, strong adhesion, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, content of the invention will be further described:

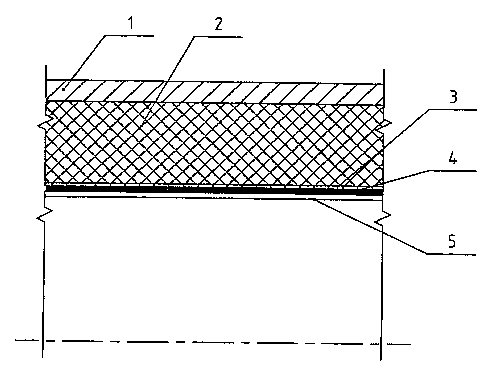

[0010] With reference to the accompanying drawings, a thermal insulation device for the inner cavity of an autoclave includes laying heat-insulating ceramic fibers 2 in the shell 1, and galvanized wire mesh 3 for fixing the heat-insulating ceramic fibers 2, and then laying heat-insulating ceramic fibers 2 on the inner surface of the heat-insulating ceramic fibers 2. Spray a layer of high-temperature-resistant bonding paint 4 to solidify the surface of the heat-insulating ceramic fiber 2 to form a cured layer, and integrate the surface of the heat-insulating material to prevent high-pressure and high-temperature air in the shell from entering the heat-insulating layer. Layer stainless steel guard plate 5, mainly is to protect solidified layer, prevents that workpiece in the autoclave collides and destroys solidified layer.

[0011] During construction, first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com