Discharge ionization current detector

A current detector and discharge ionization technology, applied in the field of discharge ionization current detectors, can solve the problems of wide dynamic range, low dynamic range, and insufficient FID detectable amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

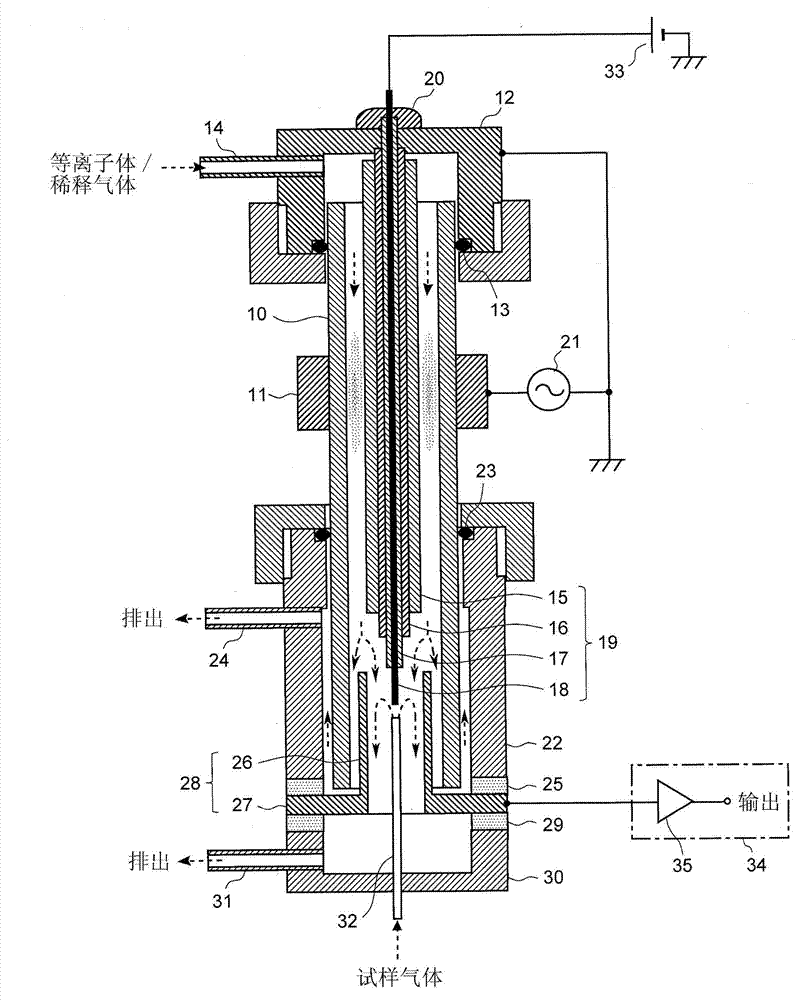

[0096] The following reference figure 1 A discharge ionization current detector according to an embodiment (first embodiment) of the present invention will be described. figure 1 is a schematic configuration diagram of the discharge ionization current detector according to the first embodiment.

[0097]The discharge ionization current detector of this embodiment has an outer dielectric tube 10 ("dielectric tube" in this embodiment) made of a dielectric material such as quartz. For example, as the outer dielectric tube 10, a quartz tube having an outer diameter of 7 mm and an inner diameter of 5 mm can be used. On the outer surface of the outer dielectric tube 10, a ring-shaped electrode 11 ("plasma generation excitation electrode" in this embodiment) made of metal (for example, stainless steel or copper) is provided circumferentially.

[0098] An upper side adapter 12 in the form of a cylinder whose upper side is closed and whose lower side is open is attached to the upper...

no. 2 example

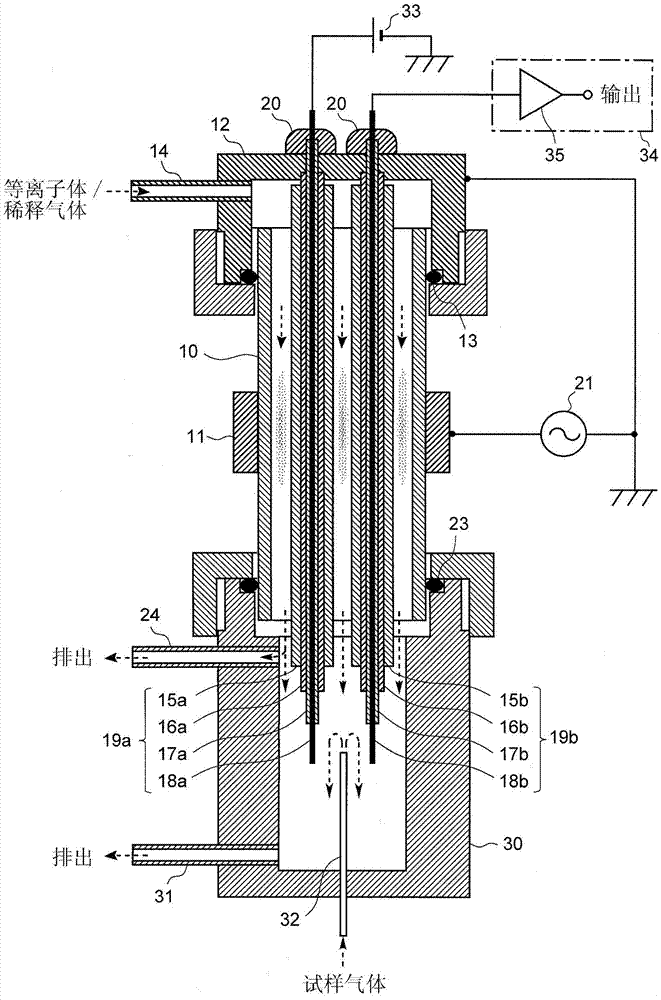

[0119] The following reference figure 2 A discharge ionization current detector according to another embodiment (second embodiment) of the present invention will be described. figure 2 is a schematic configuration diagram of a discharge ionization current detector according to the second embodiment. In this figure, the same components as those used in the first embodiment are denoted by the same reference numerals, and explanations for these components will be appropriately omitted.

[0120] The discharge ionization current detector according to this embodiment is different from the first embodiment in that the detector has two electrode structures in which no flanged metal tube is used and the An integral assembly (hereinafter referred to as "lower adapter 30") replaces the intermediate adapter and the lower adapter.

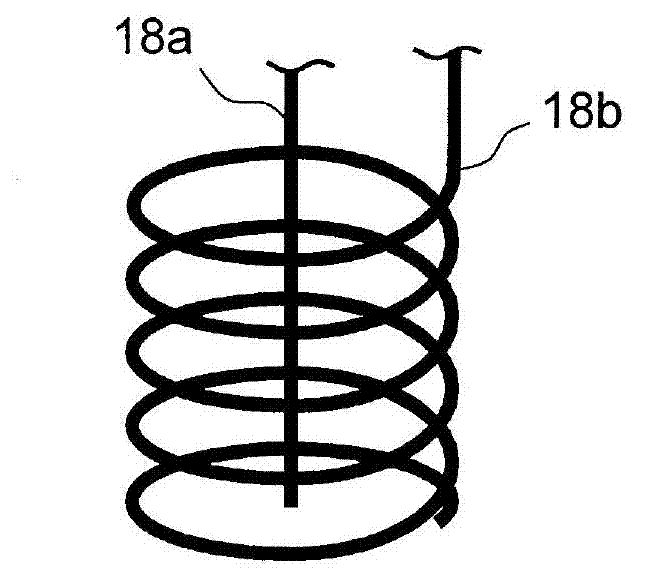

[0121] The two electrode structures in this embodiment (hereinafter referred to as "first electrode structure 19a" and "second electrode structure 19b") ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com