Vacuum heat-insulation high-efficient energy-saving electric-heating cooker

A technology for vacuum heat insulation and electric heating cookers, which is applied in home appliances, kitchen appliances, heating devices, etc., can solve problems such as waste of heat energy, minimize power consumption, and ensure energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

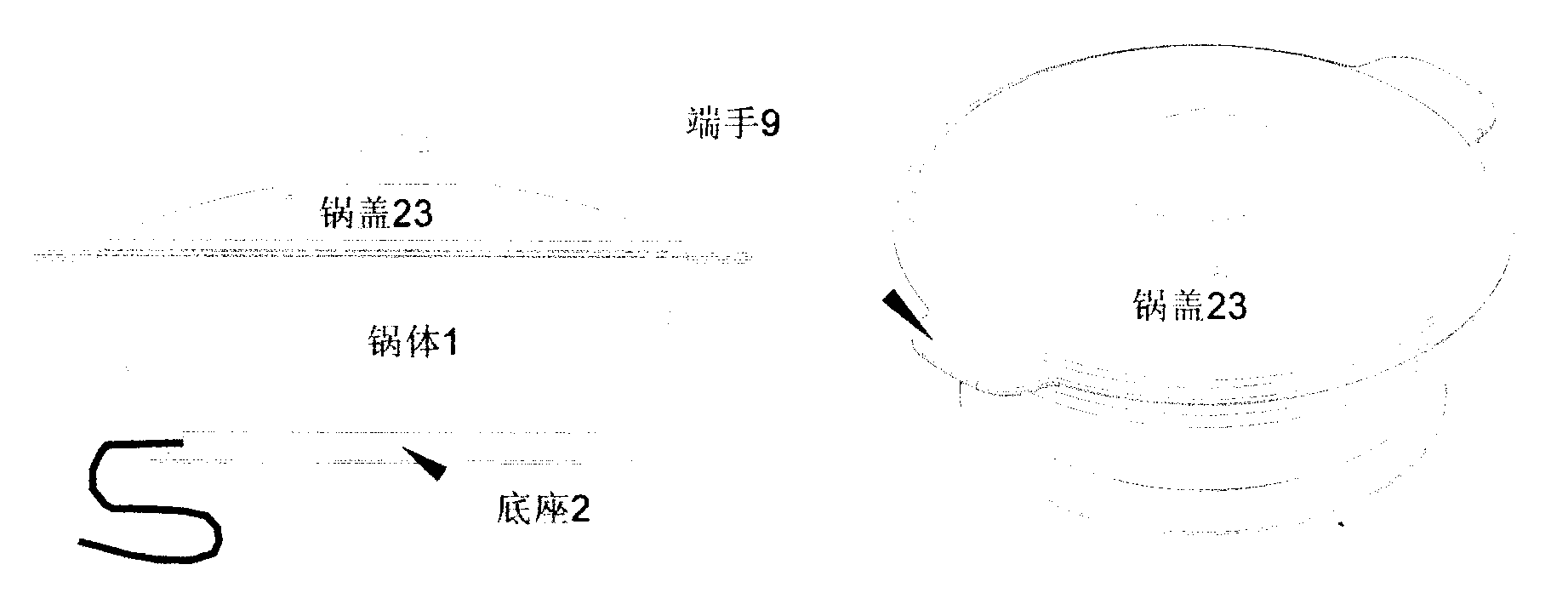

[0076] Embodiment one : Fully transparent vacuum insulated electric hot pot

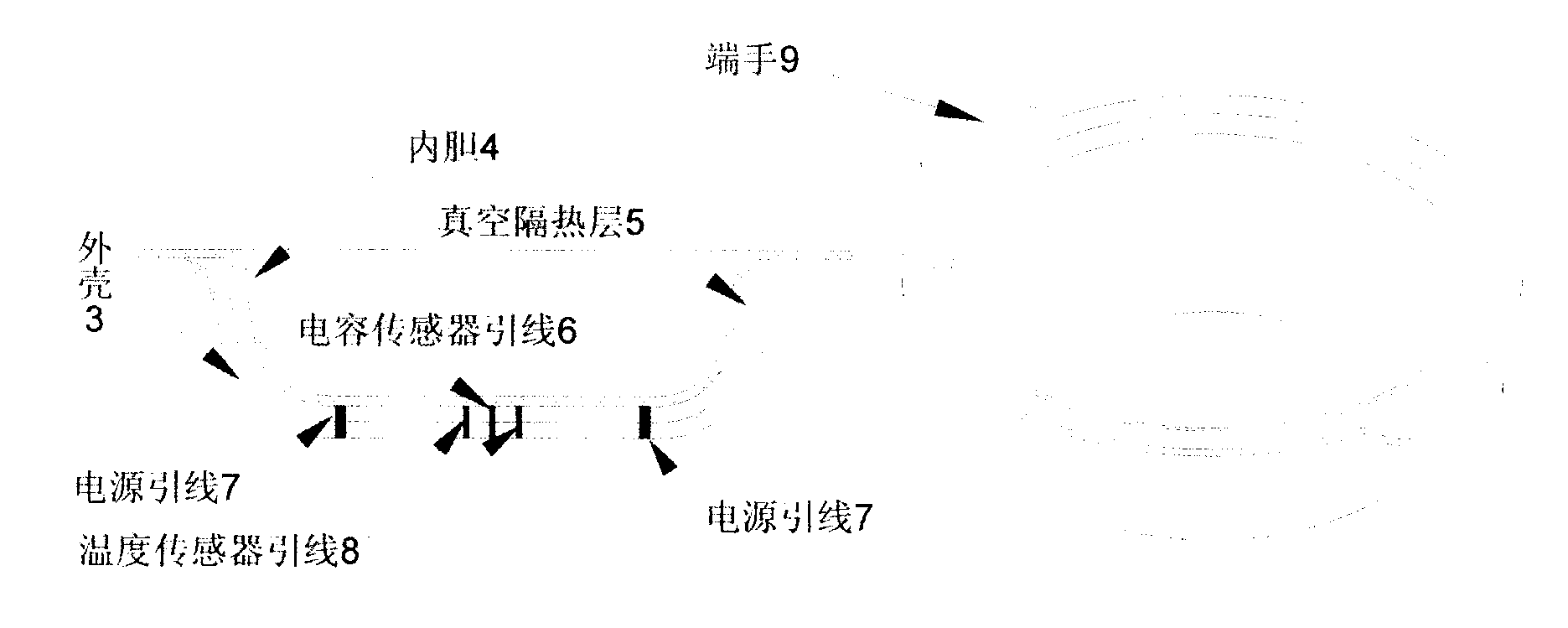

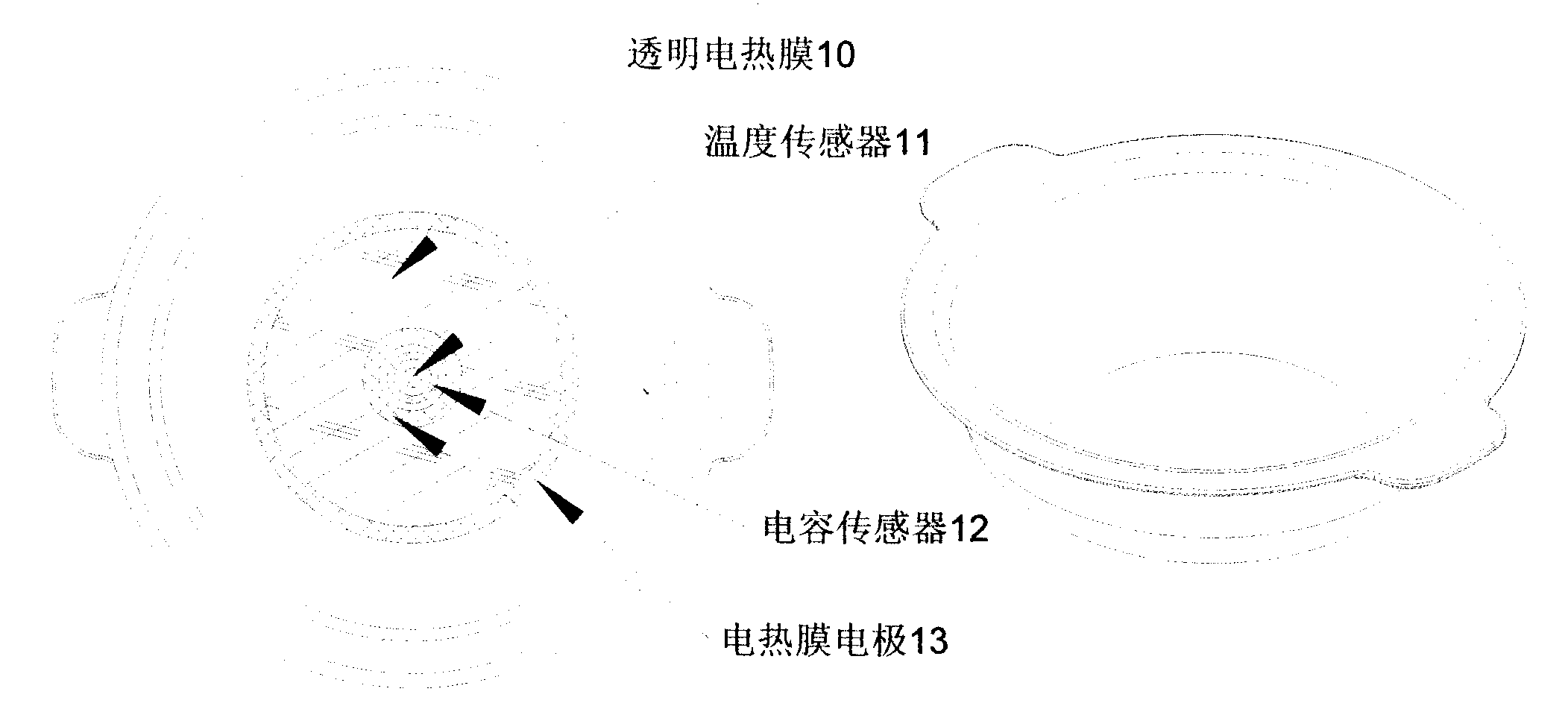

[0077]The base 2 and the glass shell 3 are made of toughened glass, and the glass liner 4 is made of heat-resistant glass. The glass shell 3 and the glass liner 4 are assembled into a closed whole with a gap of 3-5mm in the middle by melting or bonding. Vacuumize the gap to form a vacuum insulation layer 5 . Make nano-transparent electrothermal film 10, electrothermal film electrode 13, temperature sensor 11, capacitive sensor 12 etc. at the bottom of glass liner 4, through the temperature sensor electrode 11, heat conduction sensor electrode 12, electrothermal film electrode 13 of lead wire and glass shell 3 bottoms connected; the bottom of the glass case 3 is made with a positioning tenon 22; the inside of the base 2 is equipped with a power circuit, a control circuit, and a protection circuit; Contact 18, power contact 17, temperature sensor contact 19, when the pot body 1 is correctly placed o...

Embodiment 2

[0078] Embodiment two : Transparent vacuum insulated electric soup cooker

[0079] The biggest difference between this embodiment and Embodiment 1 is that the depth of the soup pot in this embodiment is far greater than that of the electric hot pot, and the glass liner 4 in this embodiment can also be made of ceramics, purple sand pottery and other materials.

[0080] The base 2 and the glass shell 3 are made of tempered glass, the inner tank 4 is made of heat-resistant glass or heat-conducting ceramics, and purple sand pottery, and the glass shell 3 and the inner tank 4 are assembled into a gap of 3 to 5 mm by melting or bonding. The airtight whole, the gap is vacuumed to form a vacuum insulation layer 5. Make nano-transparent electrothermal film 10, electrothermal film electrode 13, temperature sensor 11, capacitive sensor 12, etc. at the bottom of liner 4, and connect to temperature sensor electrode 11, heat conduction sensor electrode 12, electrothermal film electrode 13...

Embodiment 3

[0082] Embodiment three : Fully transparent vacuum insulated self-heating lunch box

[0083] The glass shell 3 and the glass box cover 21 are made of tempered glass, the glass liner 4 is made of heat-resistant glass, and the power interface 22 is made at an appropriate position of the glass shell 3, and the power interface 22 needs to be airtight to ensure vacuum heat insulation Layer 5 vacuum and durability.

[0084] After the food is loaded into the lunch box, cover the box lid. Because the vacuum heat insulation effect of the present invention is very effective, the temperature of the food can be kept for a long time; Turn on the power to heat up the food.

[0085] Because the food is only kept warm or slightly heated in this embodiment, the power of the electric heating film is very small, and its temperature rise is also very limited, so the control circuit can be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com