Common wall structure of reactor and flue gas inlet pipe in flue gas denitrification system

A reactor and denitrification technology, applied in chemical instruments and methods, exhaust gas devices, lighting and heating equipment, etc., can solve the problems of increasing equipment cost and maintenance cost, increasing the amount of supporting steel, high cost and heat preservation cost, and reducing equipment Quantity and corresponding maintenance costs, reducing space requirements, and ensuring the effect of structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

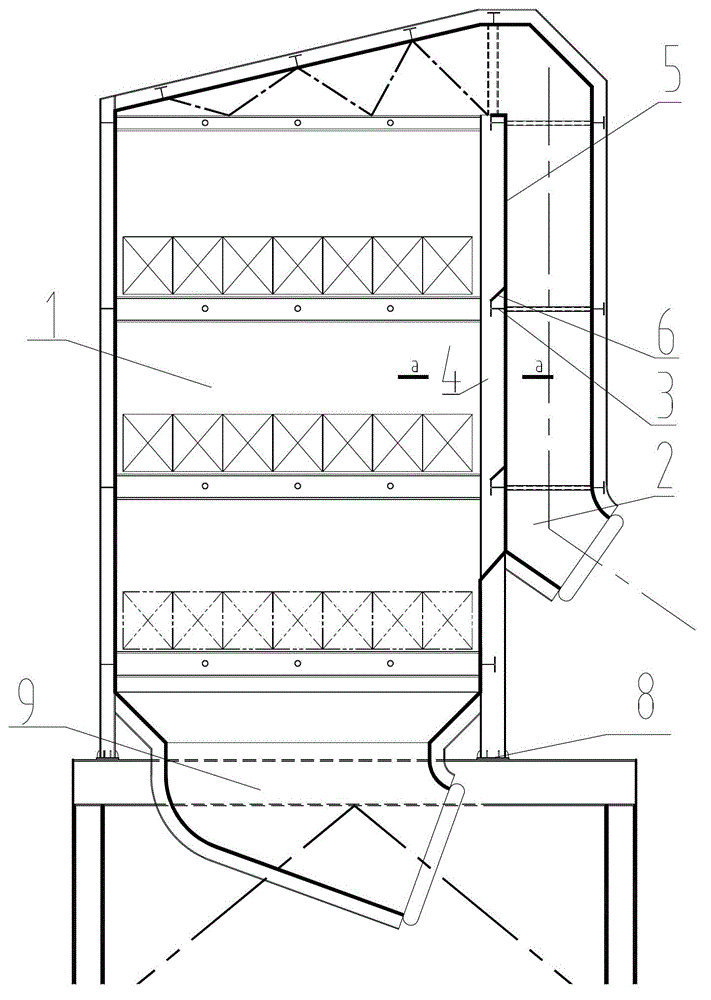

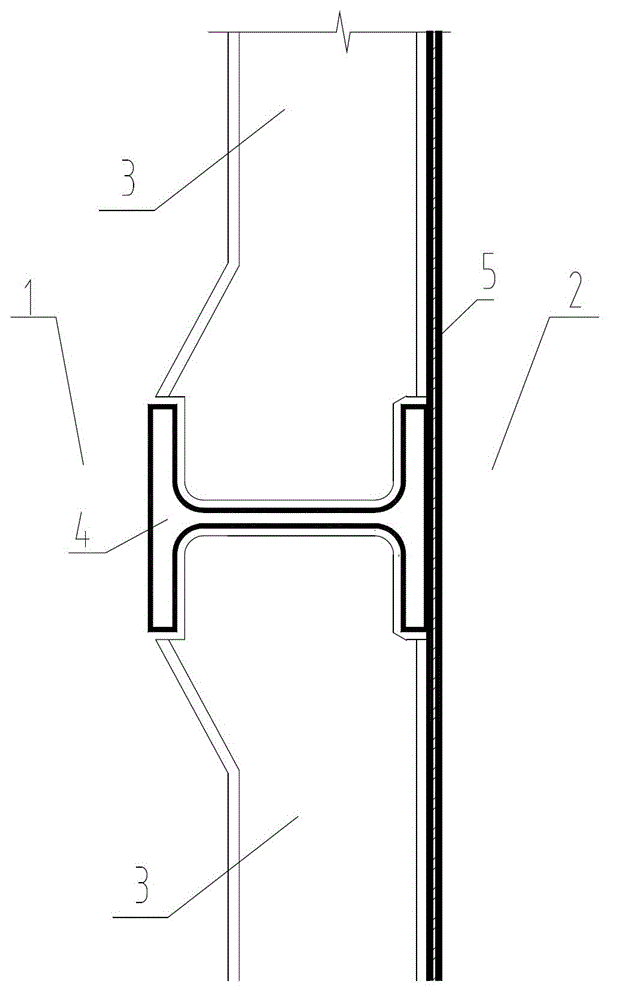

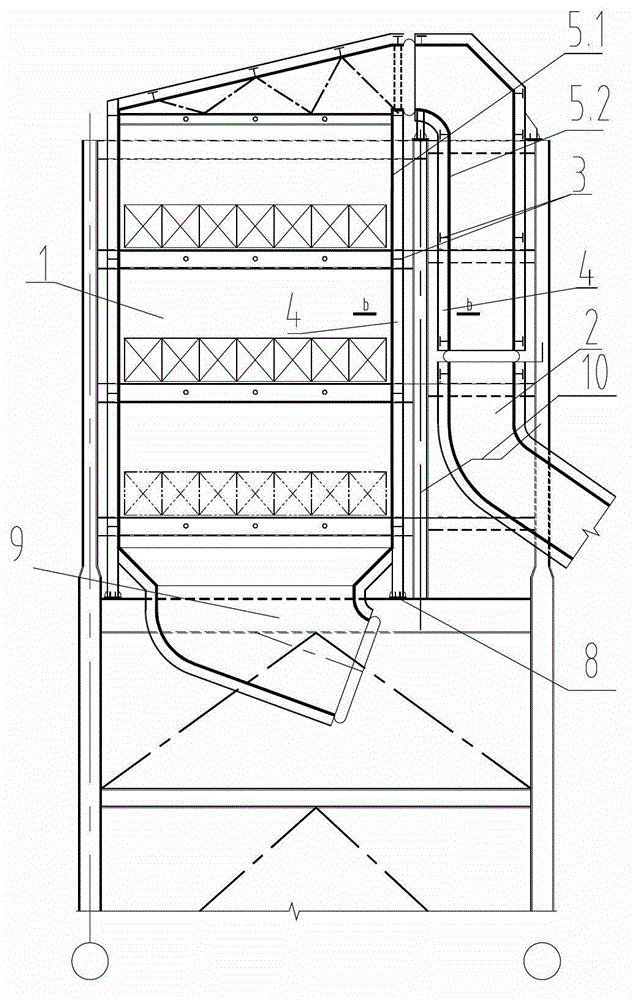

[0021] Referring to the accompanying drawings, it can be seen that the common wall structure of the reactor and the flue gas inlet pipe in the flue gas denitrification system includes the reactor 1 and the flue gas inlet pipe 2, and the lower end of the reactor 1 is correspondingly extended by its vertical stiffener 4 as the reactor support. Seat 8, the lower end of the reactor support 8 is provided with a reactor support layer girder 9, the reactor 1 is provided with a flue wall plate 5, the vertical stiffener 3 connected with the flue wall plate 5, and the vertical stiffener The horizontal stiffening ribs 4 connected with the ribs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com