Connecting method for lifting lug and automobile composite material plate spring and connecting element for connecting method

A composite material plate and connection method technology, applied in the direction of springs, springs/shock absorbers, leaf springs, etc., to achieve the effects of improving connection strength, reducing friction and impact effects, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

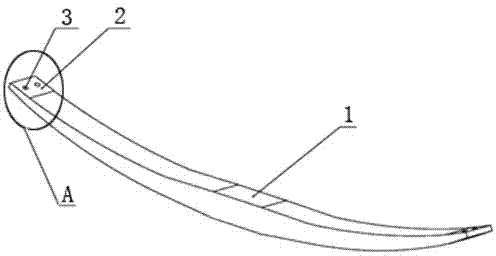

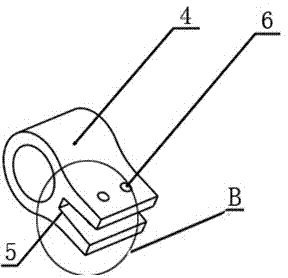

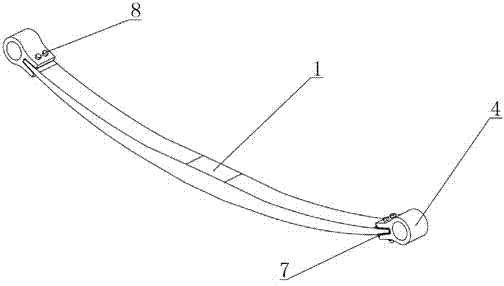

[0052] Example 1: Such as Figure 1 to Figure 5 The method for connecting the lugs of a leaf spring made of composite material for automobiles is shown in the following steps: 1) During the forming process of the leaf spring 1 made of composite material, its end is made into a wedge-shaped structure 2 with two opposite slopes, And process the end bolt holes 3; 2), process the inside of the metal lifting lug 4 into a wedge-shaped structure 5 matching the end of the composite material leaf spring, and process the bolt hole 6 on the metal lifting lug 4, the bolt hole 6 and The bolt holes 3 at the ends of the composite leaf springs correspond to each other; 3) roughen the upper and lower surfaces within the assembly length range of the end of the composite leaf spring 1, and apply A layer of adhesive layer 7; 4), assemble the composite material leaf spring 1 with the metal lifting lug 4, use bolts 8 to pass through the bolt holes of the composite material leaf spring and the met...

Embodiment 2

[0054] Example 2: Such as Figure 6 and Figure 7 The connection method and connecting parts of a composite material leaf spring lug shown are only different from Embodiment 1 in that the end of the composite material leaf spring 1 is an inverted wedge-shaped structure with two opposite slopes, and the matching The inside of the metal lug 4 is also processed into an inverted wedge structure, the cone angle 9 of which is 5°, the assembly length of the end of the composite leaf spring 1 is 80mm, and the coating thickness of the adhesive layer 7 is 1mm. In this embodiment, the assembled composite material leaf spring should be stored as a whole at a constant temperature of 65 degrees for curing for 8 hours, and after natural cooling, the finished composite material leaf spring as a whole should be obtained.

Embodiment 3

[0055] Example 3: Such as Figure 8 and Figure 9 The connection method and connecting parts of a composite material leaf spring lug shown are only different from Embodiment 1 in that the end of the composite material leaf spring 1 is a rectangular structure with two symmetrical horizontal planes, and the matching metal The inside of the lifting lug 4 is also processed into a rectangular structure, the assembly length of the end of the composite leaf spring 1 is 70 mm, and the coating thickness of the adhesive layer 7 is 0.7 mm. In this embodiment, the assembled composite material leaf spring should be stored as a whole at a constant temperature of 75 degrees for curing for 6 hours, and after natural cooling, the finished composite material leaf spring as a whole should be obtained.

[0056] To sum up, the present invention provides a method for connecting the lifting lugs of composite leaf springs of automobiles and its connectors, since the bolt connection method generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com