Dual-motor multi-mode coupling driving structure

A coupled drive, dual-motor technology, used in control devices, transportation and packaging, vehicle components, etc., can solve the problems of shifting power interruption, cumbersome control, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

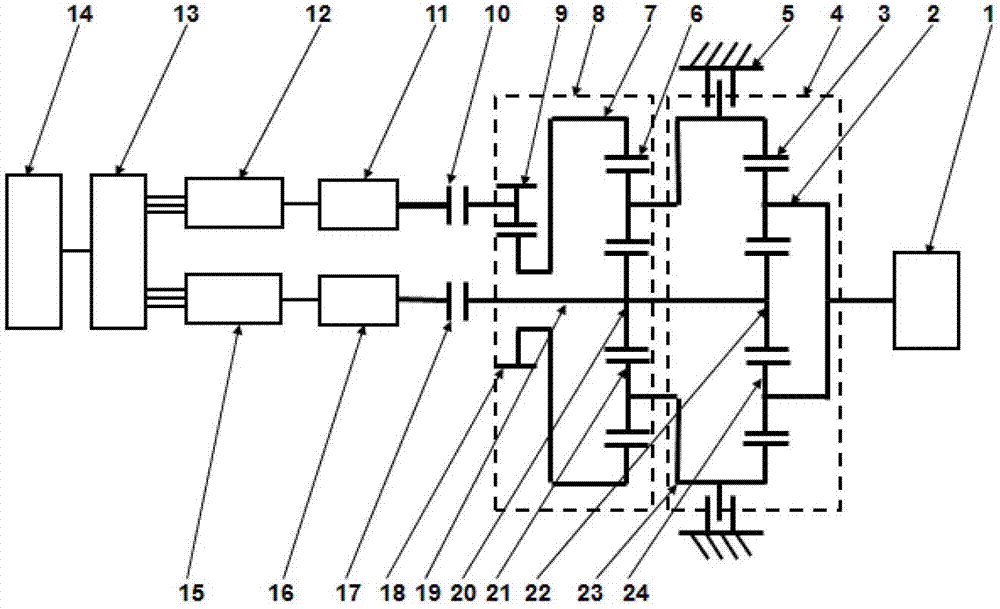

[0009] Now join the accompanying drawings for further description.

[0010] The present invention has drive axle (1), No. 2 planetary gear mechanism (4), locking device (5), No. 1 planetary gear mechanism (8), No. 2 clutch (10), No. 2 speed reducer (11), No. 2 motor (12), motor controller (13), energy storage device (14), No. 1 motor (15), No. 1 reducer (16), and No. 1 clutch (17), of which No. 2 planetary gear mechanism (4) It is composed of the No. 2 planetary carrier (2), the planetary carrier-ring gear (23), the No. 2 sun gear (22), and the No. 2 planetary gear set (24). The No. 1 planetary gear mechanism (8) is composed of the No. 1 Ring gear (7), No. 1 sun gear (20), No. 1 planetary gear set (21), planet carrier-ring gear (23), No. 1 sun gear (20), No. 2 sun gear (22) and sun gear Wheel axle (19) is manufactured as a whole. The present invention is characterized in that: No. 1 motor (15) and No. 2 motor (12) are arranged on the same side, and the power of No. 1 motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com