Centrifugal fan

A centrifugal fan and central axis technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problem of increasing wind noise of centrifugal fans, and achieve the effect of suppressing wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

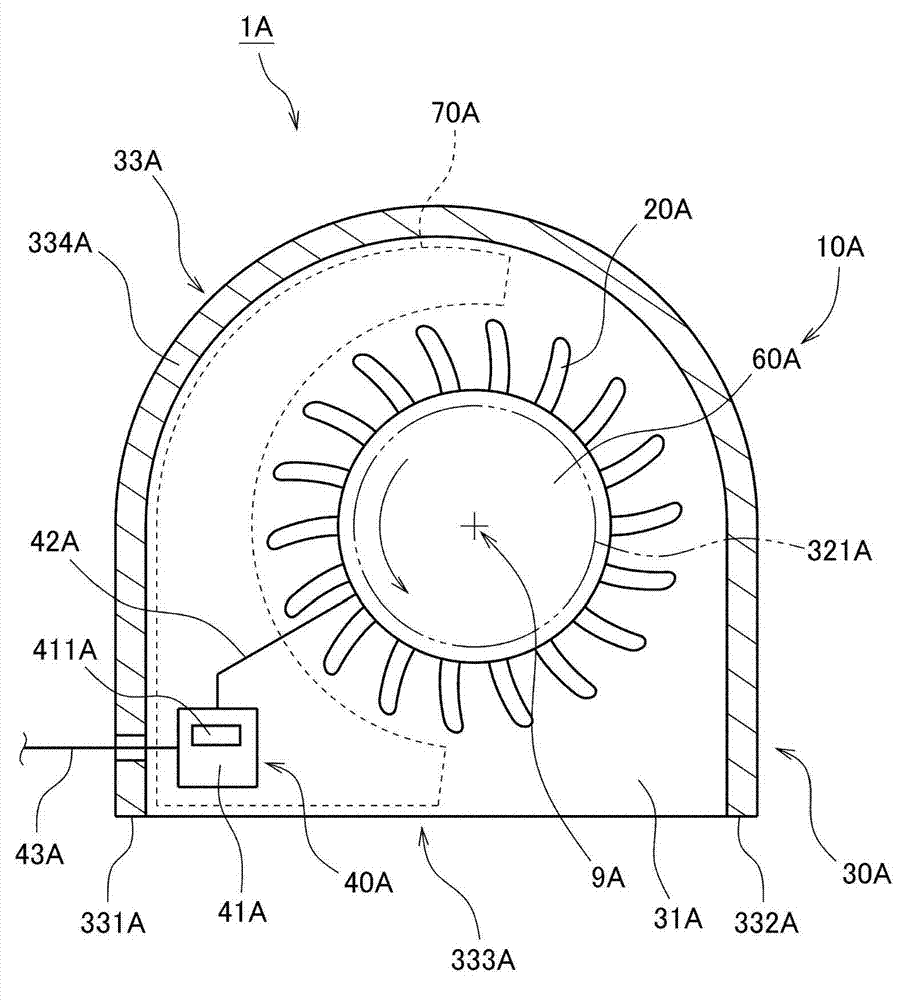

[0021] figure 1 It is a cross-sectional view of the fan 1A according to the first embodiment of the present invention. Such as figure 1 As shown, the centrifugal fan 1A has a motor 10A, an impeller 20A, a casing 30A, and a base plate 40A.

[0022] The motor 10A has a stationary part fixed to the housing 30A, and a rotating part 60A supported rotatably relative to the stationary part. The motor 10A rotates the rotating portion 60A around the central axis 9A extending up and down. The impeller 20A rotates together with the rotating part 60A. The casing 30A accommodates the rotating part 60A and the impeller 20A, and the casing 30A has an upper suction port 321 and an exhaust port 333A. The substrate 40A supplies drive current to the motor 10A.

[0023] The casing 30A has a bottom plate 31A, a top plate, and a side wall 33A. The bottom plate 31A extends in a direction substantially perpendicular to the central axis 9A on the lower side of the impeller 20A. Furthermore, the...

no. 2 approach

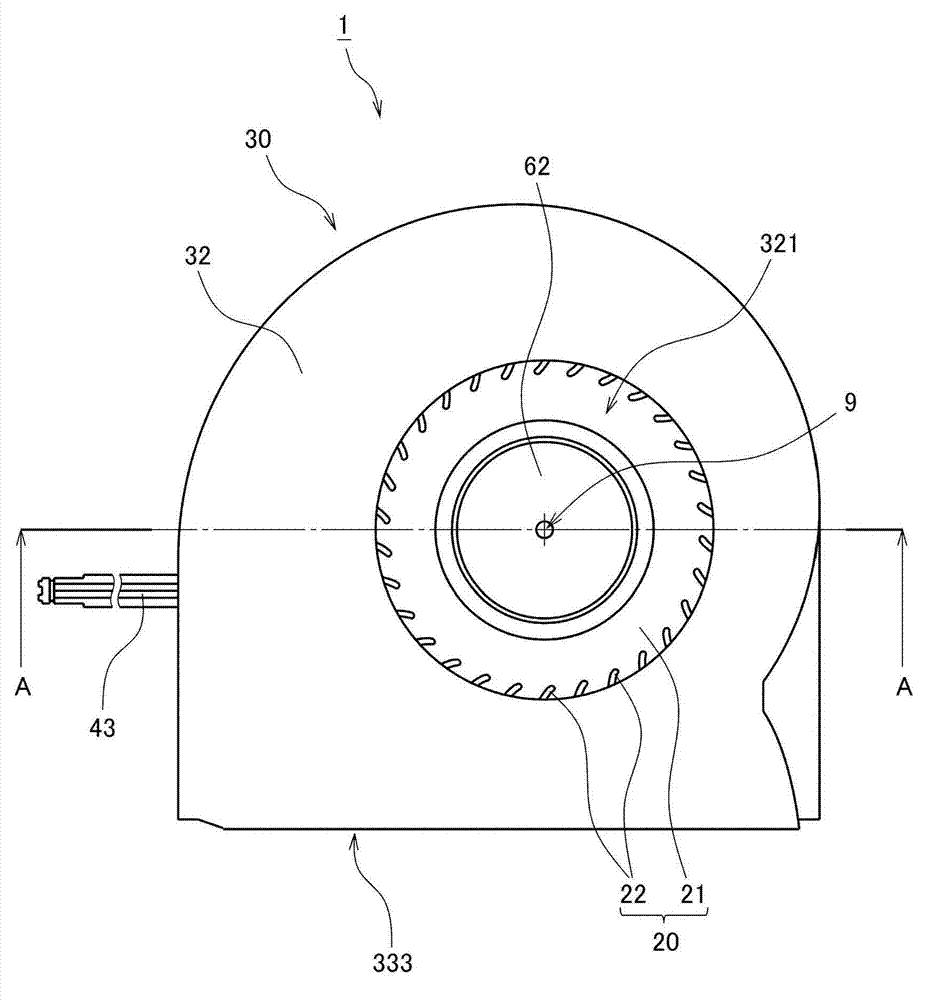

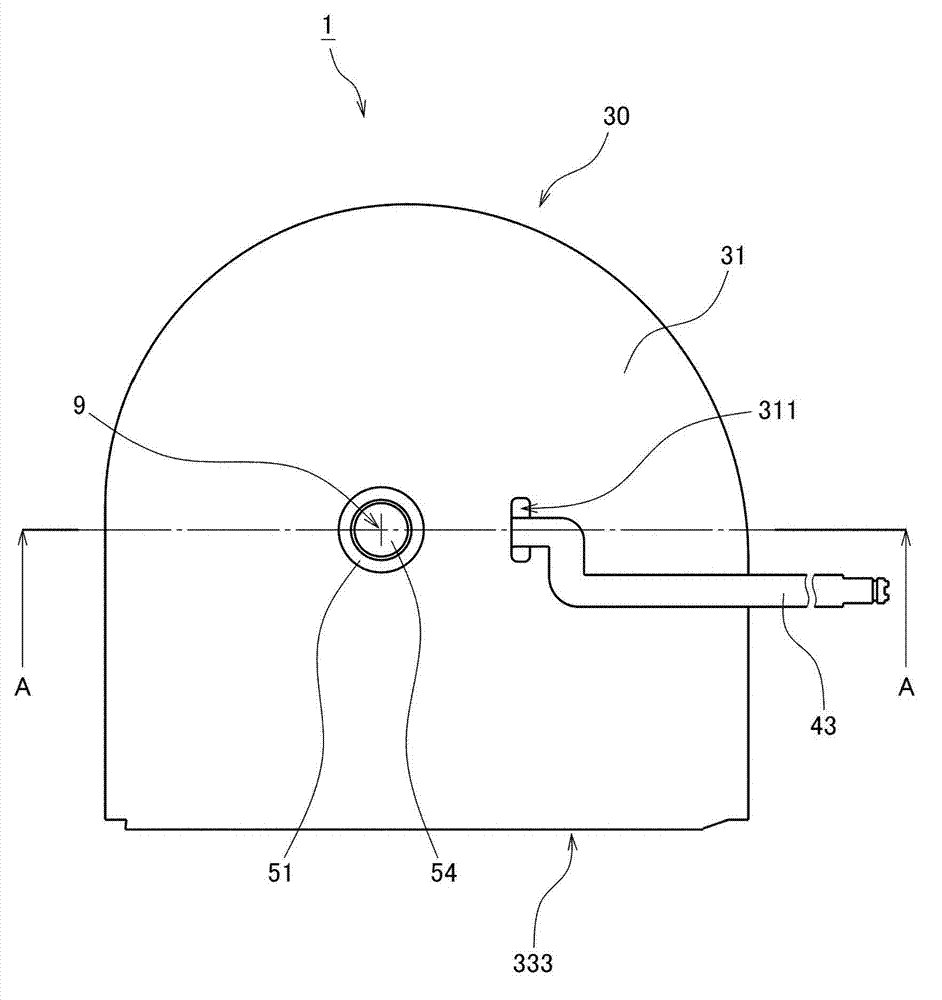

[0029] Next, a second embodiment of the present invention will be described. figure 2 It is a top view of the centrifugal fan 1 which concerns on 2nd Embodiment. image 3 It is the bottom view of the centrifugal fan 1. Figure 4 is a cross-sectional view of the centrifugal fan 1 . Figure 5 From Figure 2 to Figure 4 A vertical cross-sectional view of the centrifugal fan 1 observed at position A-A in .

[0030] This centrifugal fan 1 is installed in electronic equipment such as a notebook personal computer, and is used to cool the inside of the electronic equipment. Such as Figure 2 to Figure 5 As shown, the centrifugal fan 1 of this embodiment has a motor 10 , an impeller 20 , a casing 30 and a base plate 40 .

[0031] The motor 10 rotates the impeller 20 according to the drive current. Such as Figure 5 As shown, the motor 10 has a stationary part 50 fixed to the casing 30 , and a rotating part 60 rotatably supported relative to the stationary part 50 . The motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com