Vehicle drive device

A driving device and vehicle technology, which is applied in the direction of transmission device, electrical device, power device, etc., can solve the problems of difficulty in realizing the driving device, increase in radial size, and difficulty in ensuring the diameter of the hydraulic coupling fully, and achieve the purpose of suppressing the shaft To the effect of size expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

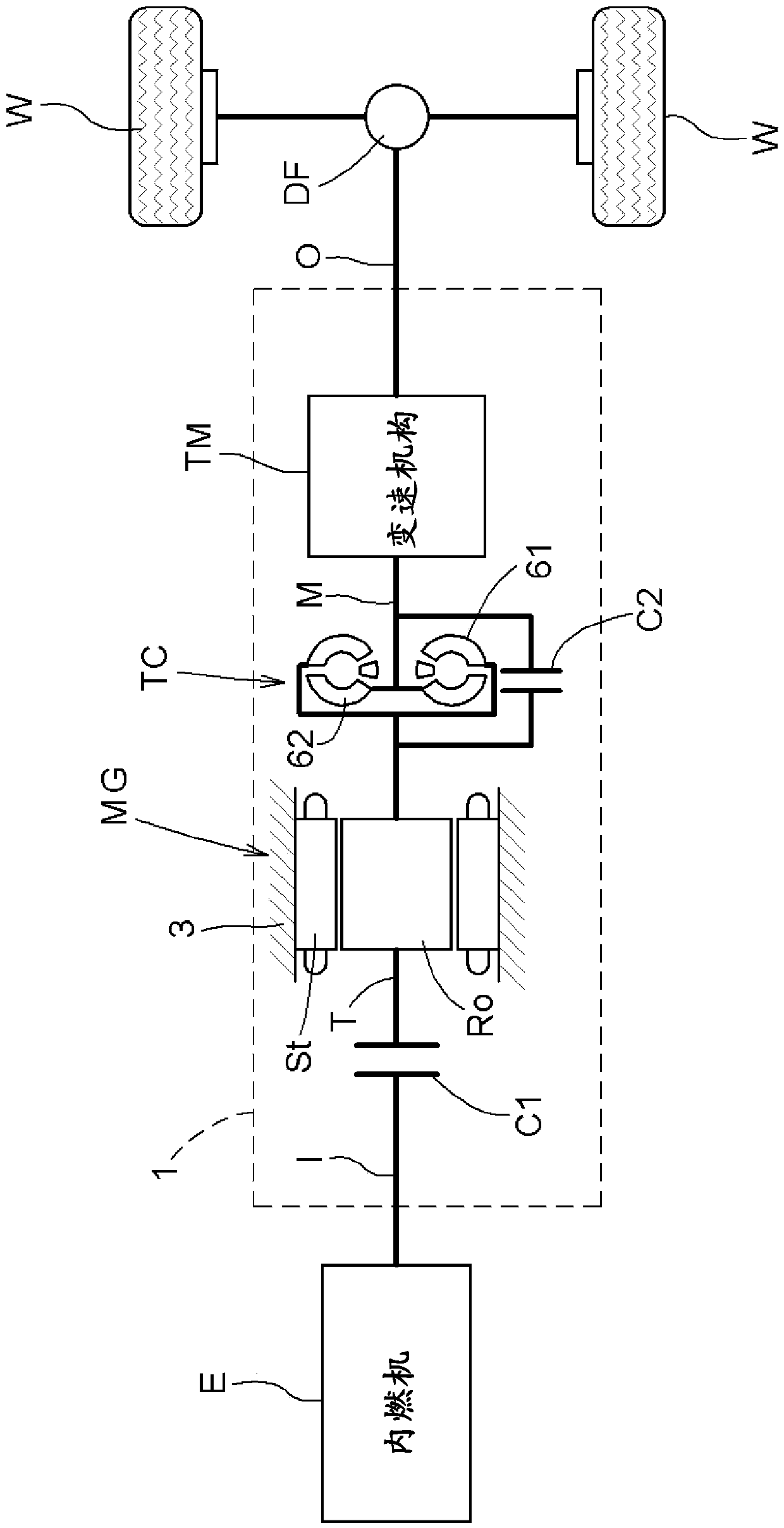

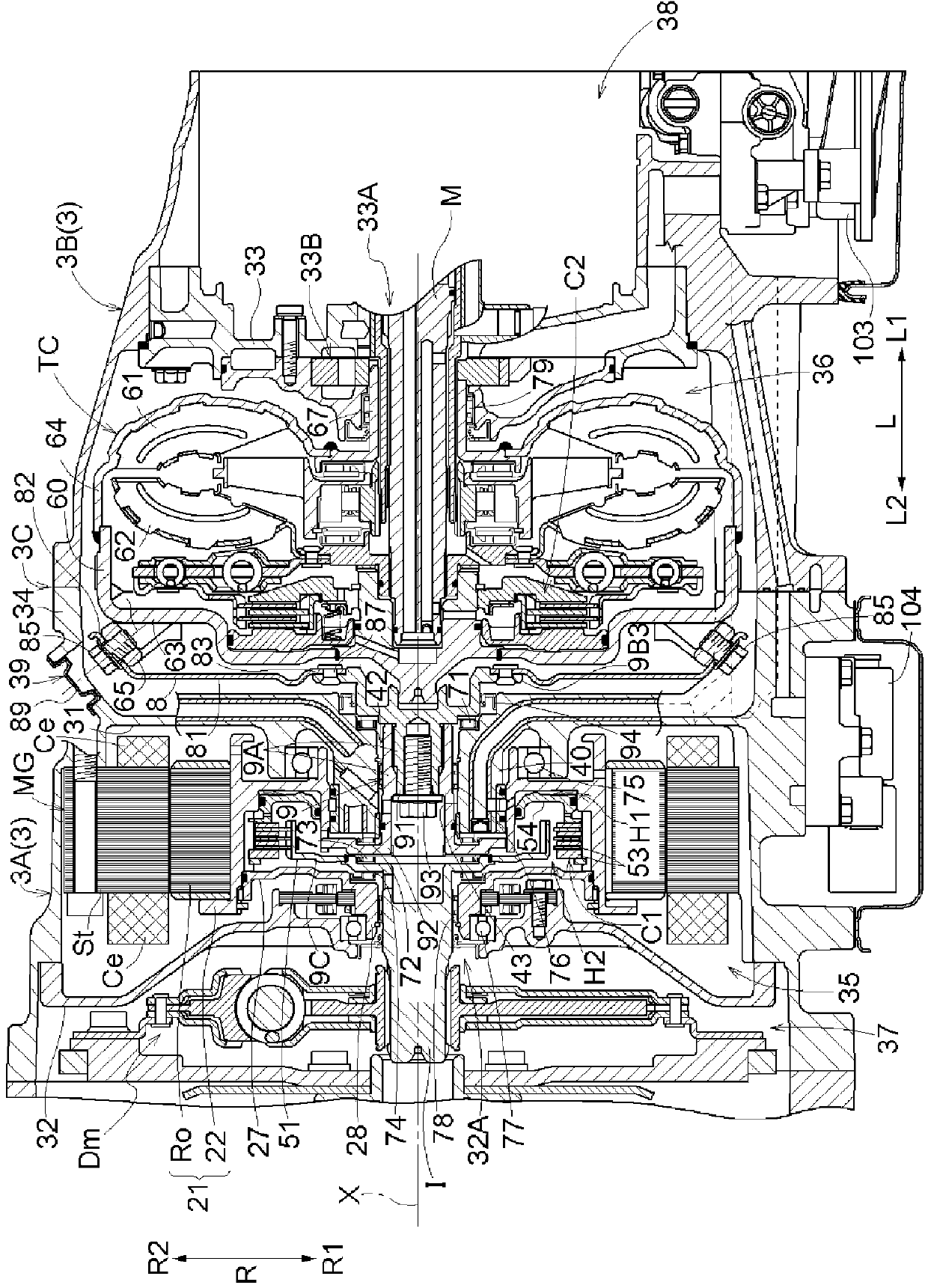

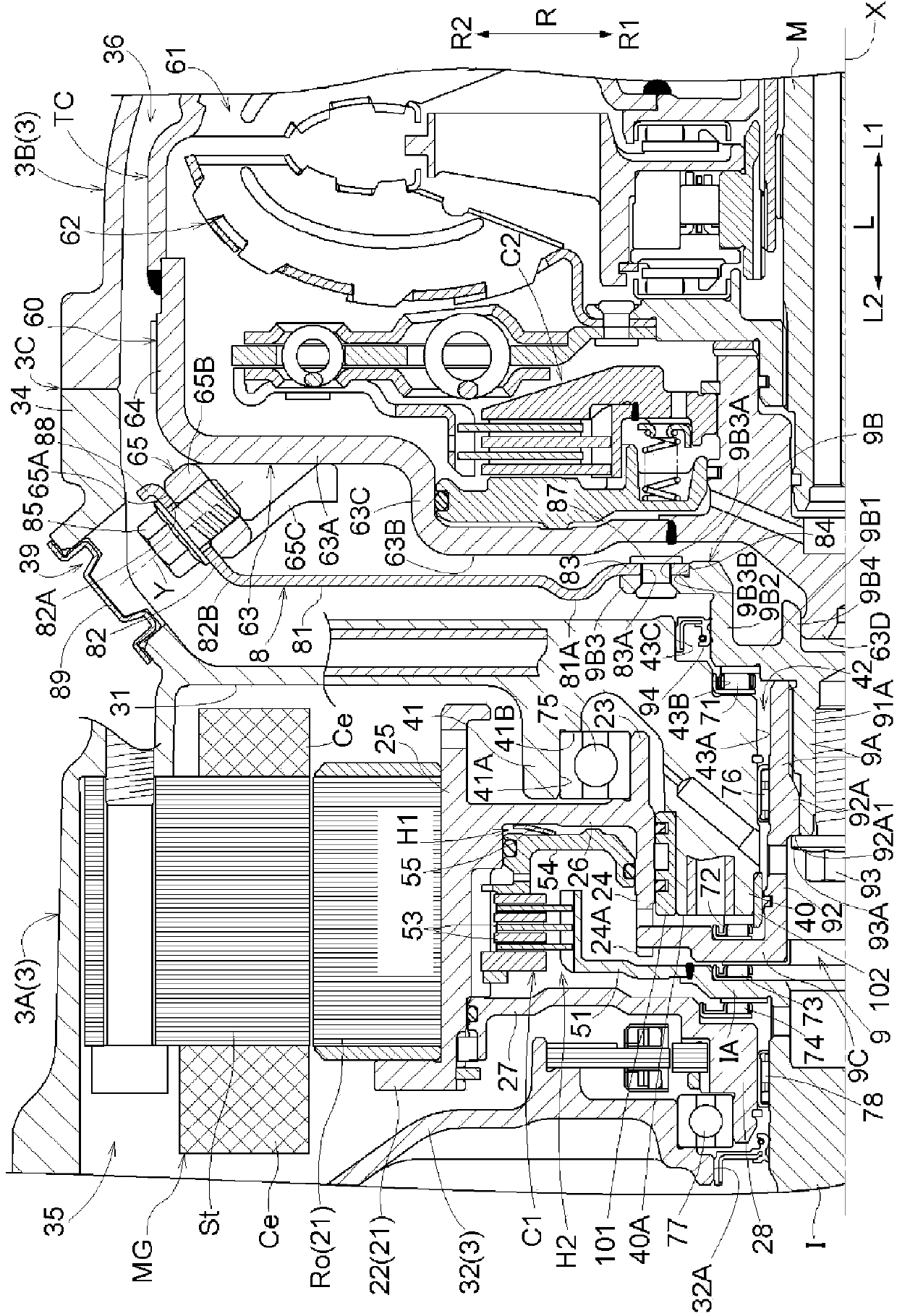

[0033] Embodiments of the vehicle drive device according to the present invention will be described with reference to the drawings. In addition, in the following description, unless otherwise specified, the rotation axis of the rotary electric machine MG ( figure 2 "Axial direction L", "radial direction R", and "circumferential direction" are defined based on the axis X) shown. Also, "axis first direction L1" means a direction along the axial direction L from the side of the rotary electric machine MG toward the side of the torque converter TC ( figure 2 The right side in ), "Axis second direction L2" indicates the direction opposite to the first axis direction L1 ( figure 2 left in ). In addition, the "radial inner direction R1" indicates the direction toward the inner side in the radial direction R, and the "radial outer direction R2" indicates the direction toward the outer side in the radial direction R. In addition, the direction of each component indicates the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com