Light-emitting diode (LED) lamp capable of improving light uniformity

A technology of uniformity of LED lights, applied in the direction of semiconductor devices, light sources, lampshades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

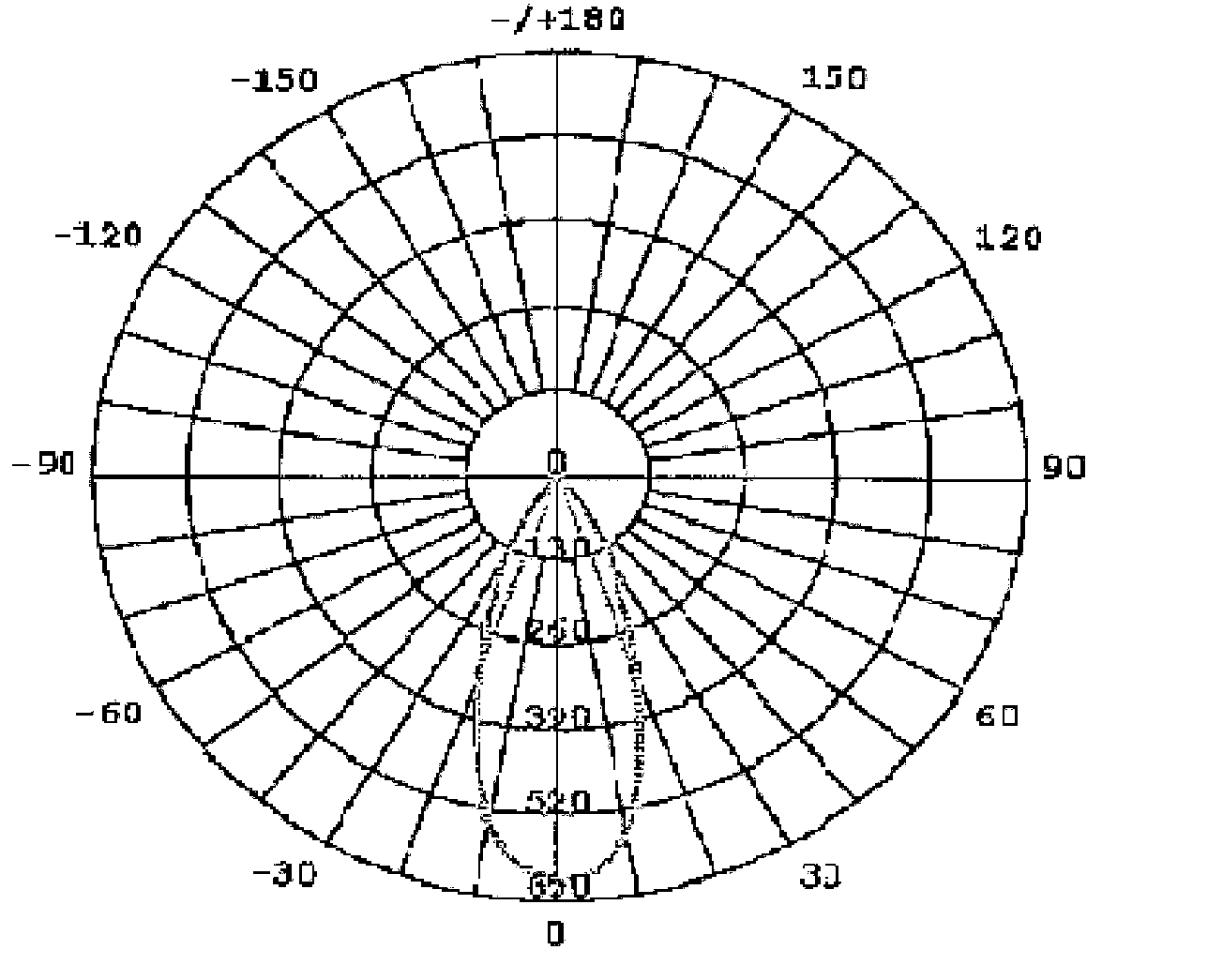

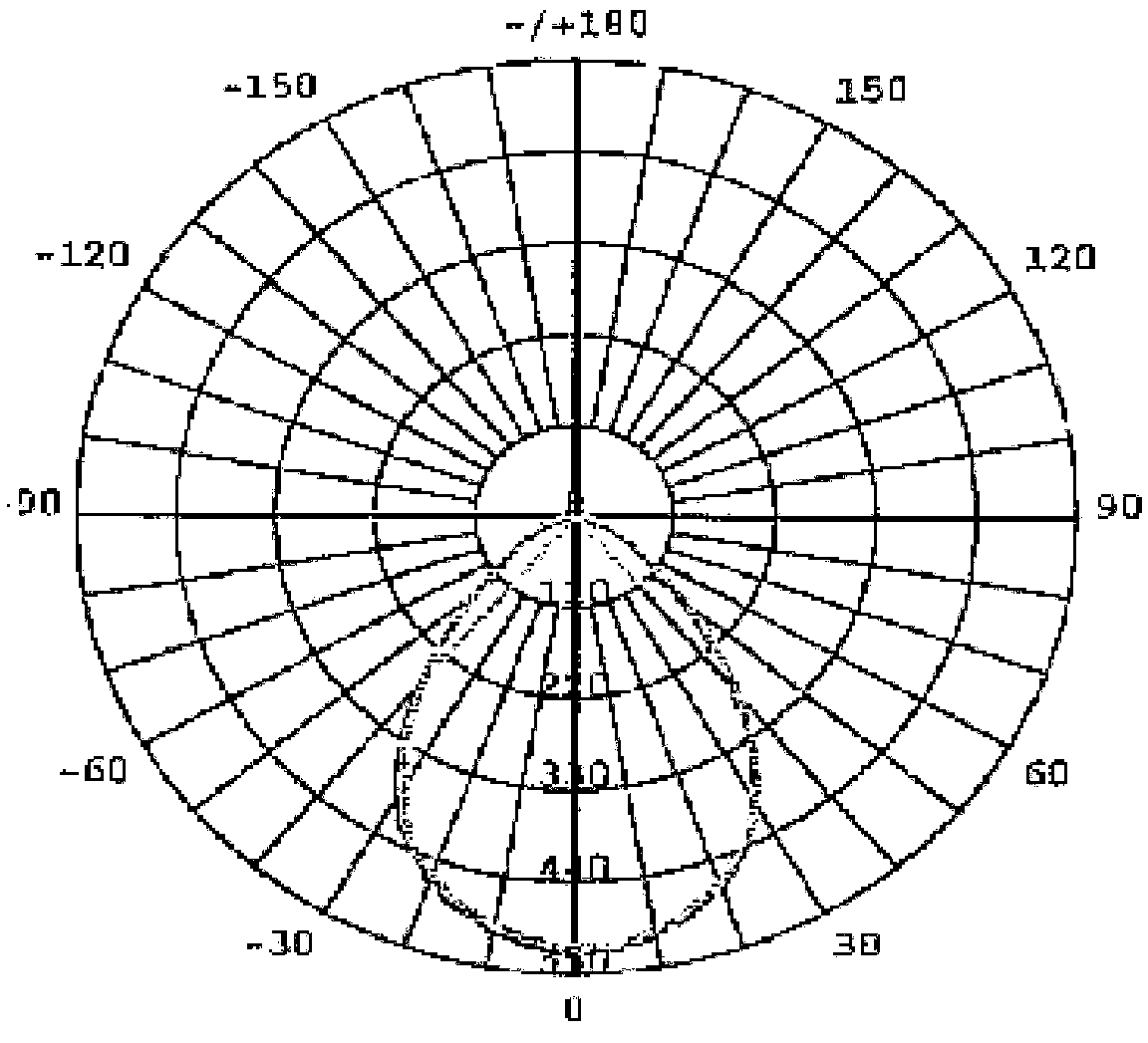

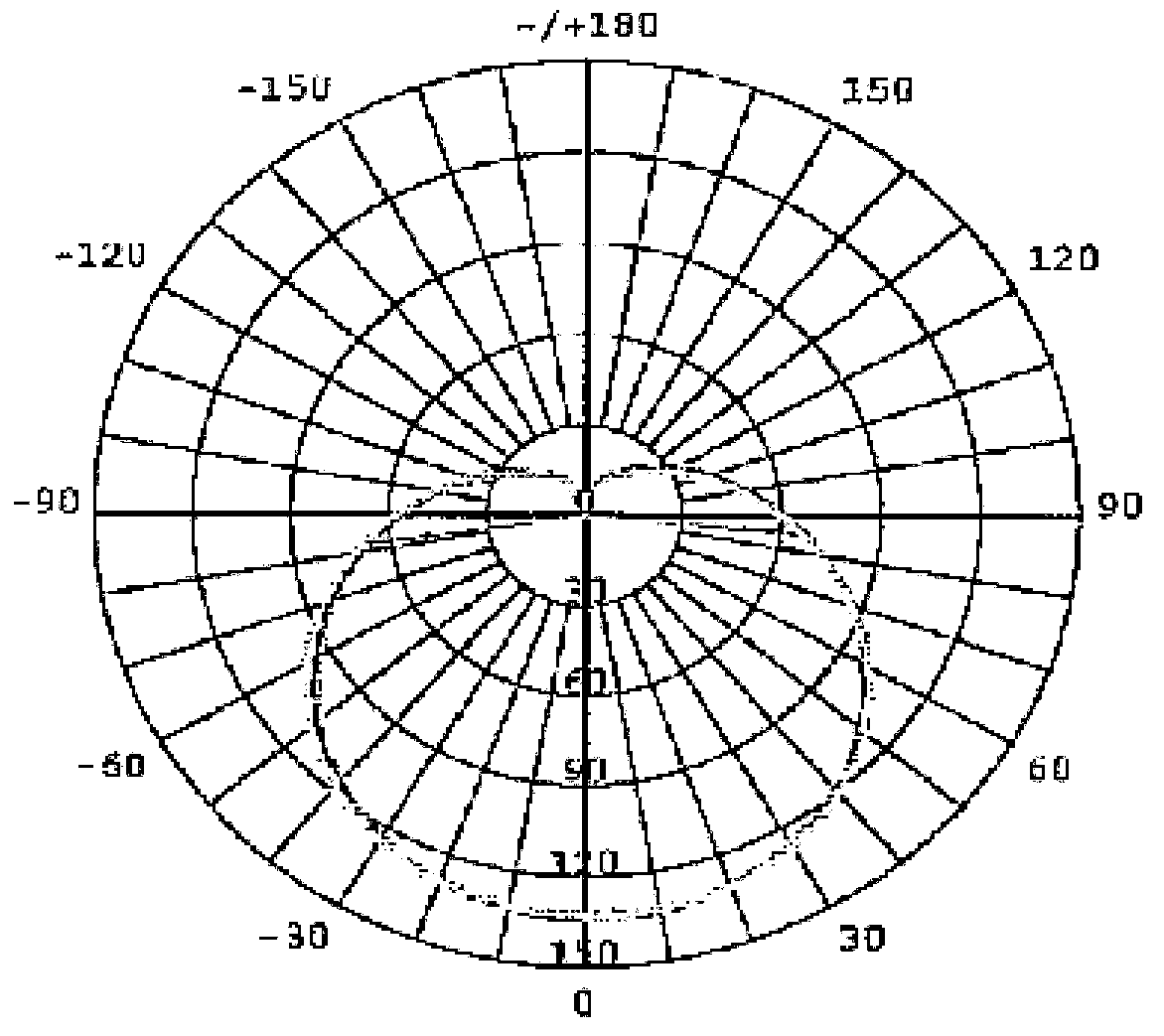

[0033] The structure of the LED lamp for improving light uniformity provided by this embodiment is shown in the figure, including a lamp cap 5, a heat dissipation shell 31, a light source 2, a driving power supply 4, and a lampshade 1. The inner wall of the lampshade 1 is coated with a coating 14, so The thickness of the coating 14 gradually changes from thick to thin from the top 15 of the lampshade to the open ends 16a, 16b; the coating 14 is formed by mixing glue and particles, and the particles are transparent particles. In this embodiment, the lampshade 1 is made of glass, the glue is silica gel, and the particles are silica with an average particle size of 100 microns. The silica and silica gel are mixed to form a mixture with a mass concentration of 25% silica and then heated and cured.

[0034] After the coating is cured, the thickness of the coating is 5 mm at the thickest part on the top 15 of the lampshade, and 1 mm at the thinnest part of the coating near the open ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the lampshade 1 is made of polycarbonate (PC), the glue adopts epoxy resin, the particles adopt silicon dioxide with an average particle diameter of 0.1 micron, and the mass concentration of particles in the mixture of particles and glue It is 30%. After the coating is cured, the thickness of the thickest part of the coating on the top 1 of the lampshade is 3mm, and the thickness of the thinnest part of the coating near the open ends 16a and 16b of the LED lamp is 0.4mm. The average beam angle of the produced LED lamp was 163.9 degrees.

[0040]

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that the lampshade body is made of polymethyl methacrylate (PMMA), the glue is epoxy resin, and the particles are glass particles with an average particle diameter of 500 microns. The mass concentration is 10%. After the coating is cured, the thickness of the thickest part of the coating on the top 1 of the lampshade is 2 mm, and the thickness of the thinnest part of the coating near the open ends 16a and 16b of the LED lamp is 0.1 mm. The average beam angle of the produced LED lamp was 155.1 degrees.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com