Air-cooling direct-current frequency-conversion magnetic levitation nature cold source water chilling unit

A technology of natural cold source and DC frequency conversion, which is applied in refrigerators, refrigeration components, compressors, etc., and can solve problems such as high pressure ratio, blockage, surge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

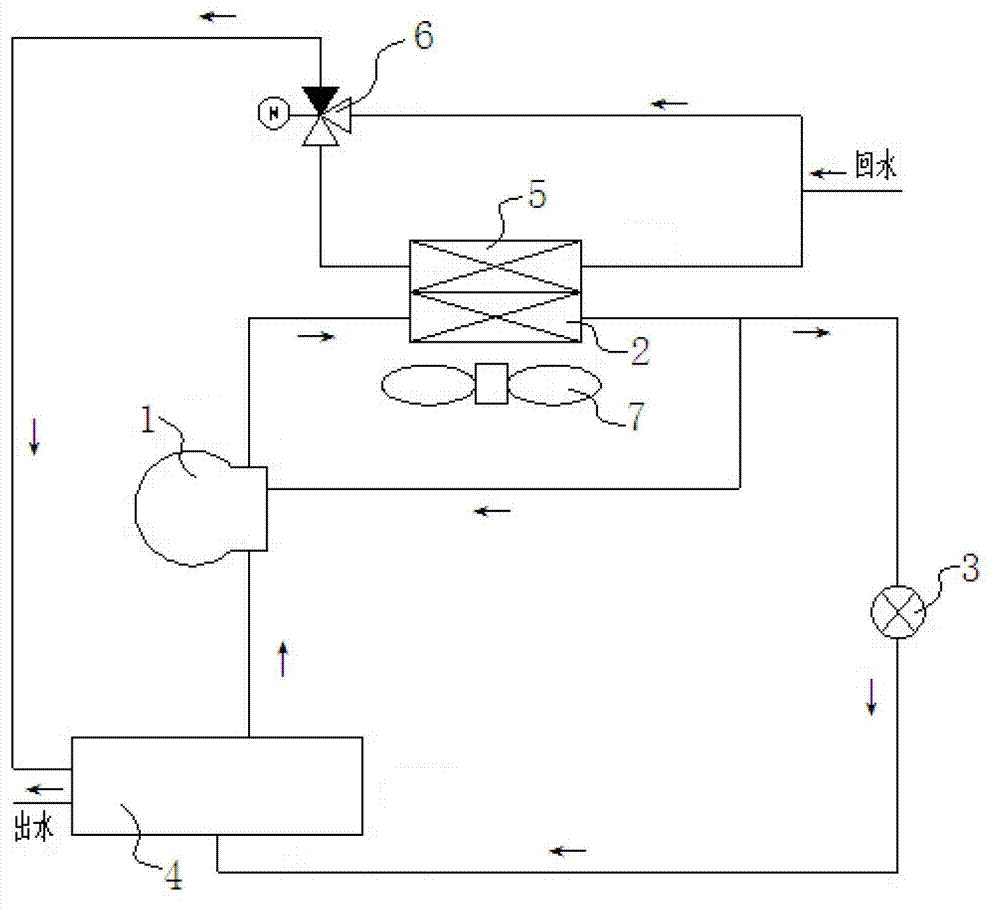

[0030] An air-cooled DC frequency conversion magnetic levitation natural cold source chiller, such as figure 1 The connection relationship of the various components shown includes two system cycles, namely the compressor cycle refrigeration system and the natural cold source cycle water system, wherein the compressor cycle refrigeration system includes a magnetic levitation compressor, an air-cooled condenser, and a throttle valve and evaporator, the outlet of the magnetic levitation compressor is connected with the air-cooled condenser, the throttle valve, and the evaporator successively through pipelines, and the steam outlet of the evaporator is communicated with the suction port of the magnetic levitation compressor, and the air-cooled The outlet of the condenser is provided with a branch and communicates with the motor cooling inlet of the magnetic levitation compressor; the natural cold source circulating water system includes two branch pipes, and a three-way valve is ar...

Embodiment 2

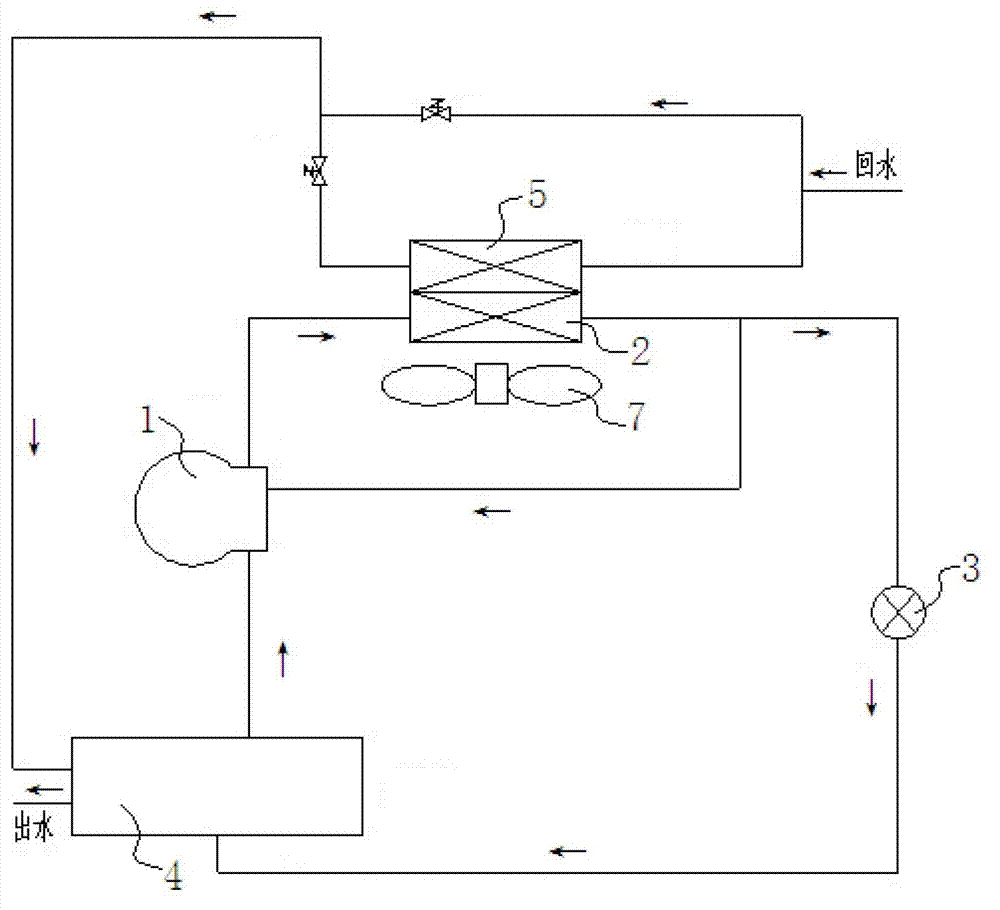

[0041] Such as figure 2 As shown, the difference between it and Embodiment 1 is that the three-way valve is replaced by two on-off control valves to achieve the same function, and the control valve can also be automatic or manual. Automatic valves can be solenoid valves, electric ball valves, electric butterfly valves, etc.; manual on-off valves can be ball valves, gate valves, butterfly valves, etc.

Embodiment 3

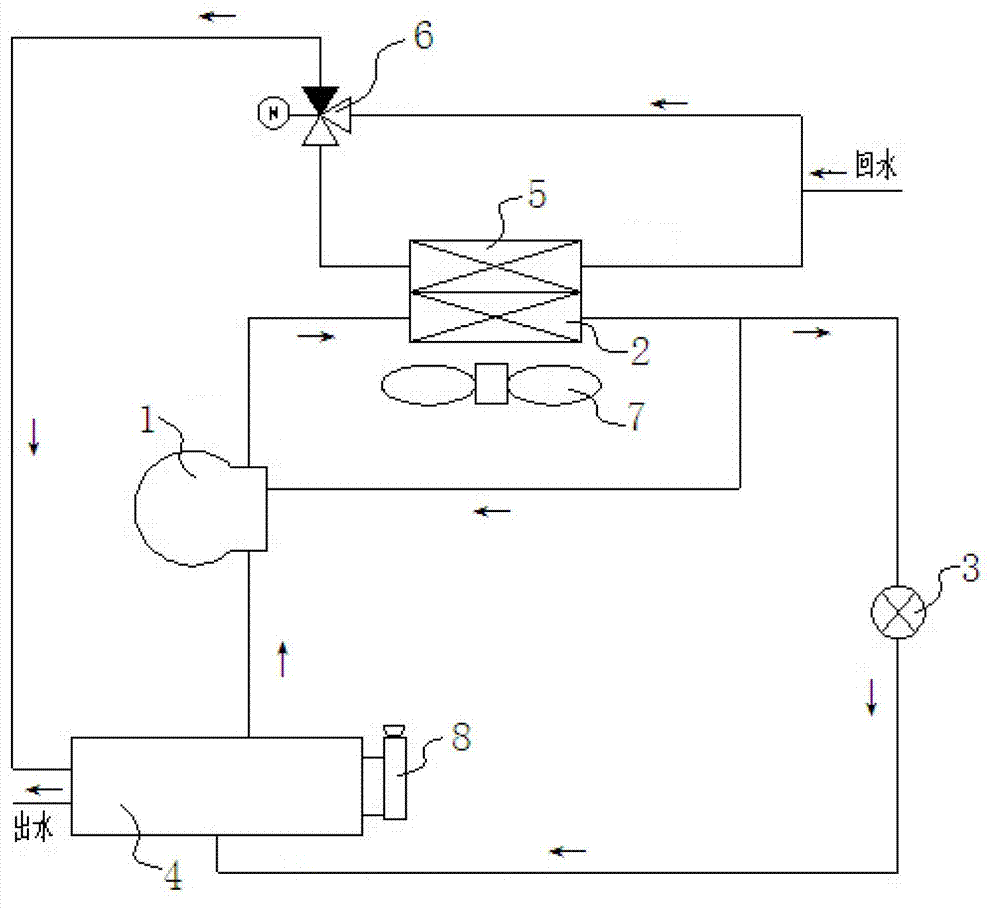

[0043] Such as image 3 As shown, its difference with embodiment 1 is that a liquid level gauge has been set up on the evaporator. This design point is mainly used to read the liquid level inside the evaporator to the control system, combined with the application of the electronic expansion valve, through the optimized control algorithm, it can still be controlled under adverse factors such as outdoor temperature changes and refrigerant flow changes. The liquid level in the evaporator is controlled more accurately at a reasonable position, which not only ensures that the heat exchange tubes are completely immersed in the refrigerant, but also ensures that the liquid refrigerant will not be poured into the compressor under any working conditions ( This is especially important for maglev compressors), which improves the heat exchange efficiency and the reliability of the product under variable load conditions throughout the year, especially when combined with natural cooling sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com