Small hole measuring mechanism

A technology of small hole measurement and measuring rod, which is applied in the field of measurement and inspection, can solve the problems that cannot meet the high precision, multi-parameter detection requirements, and difficulty in small hole measurement, and achieve the effect of simple structure, long service life and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

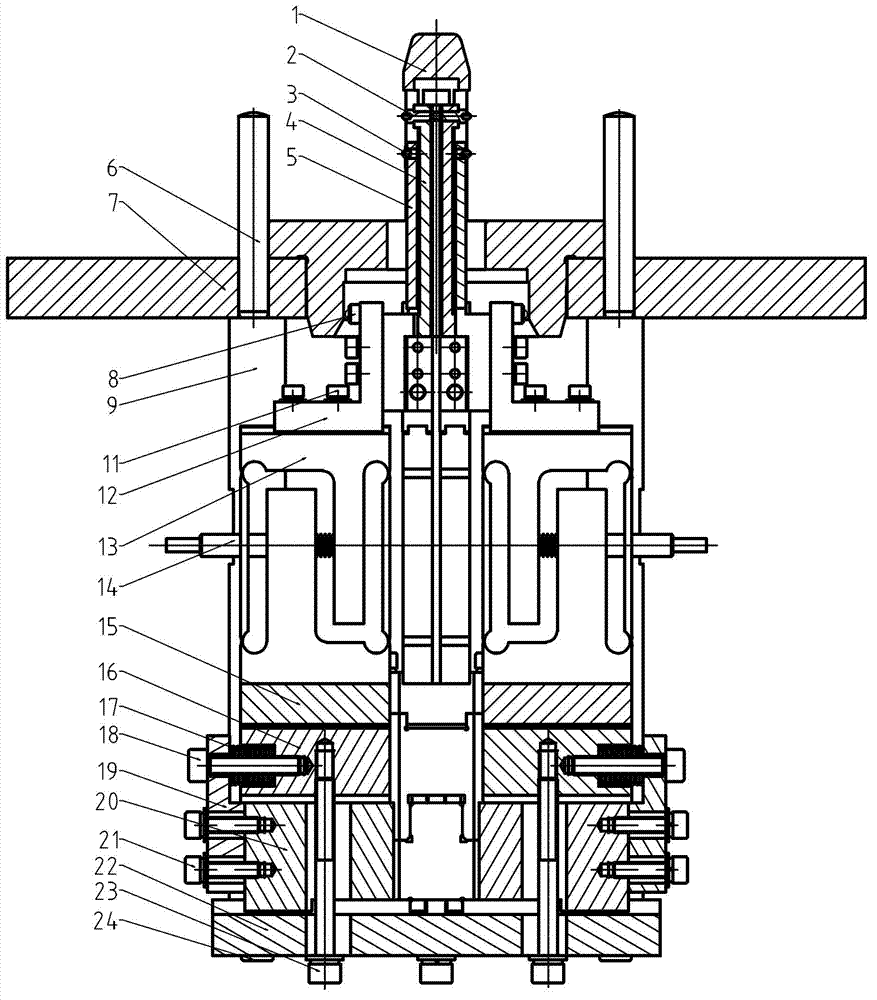

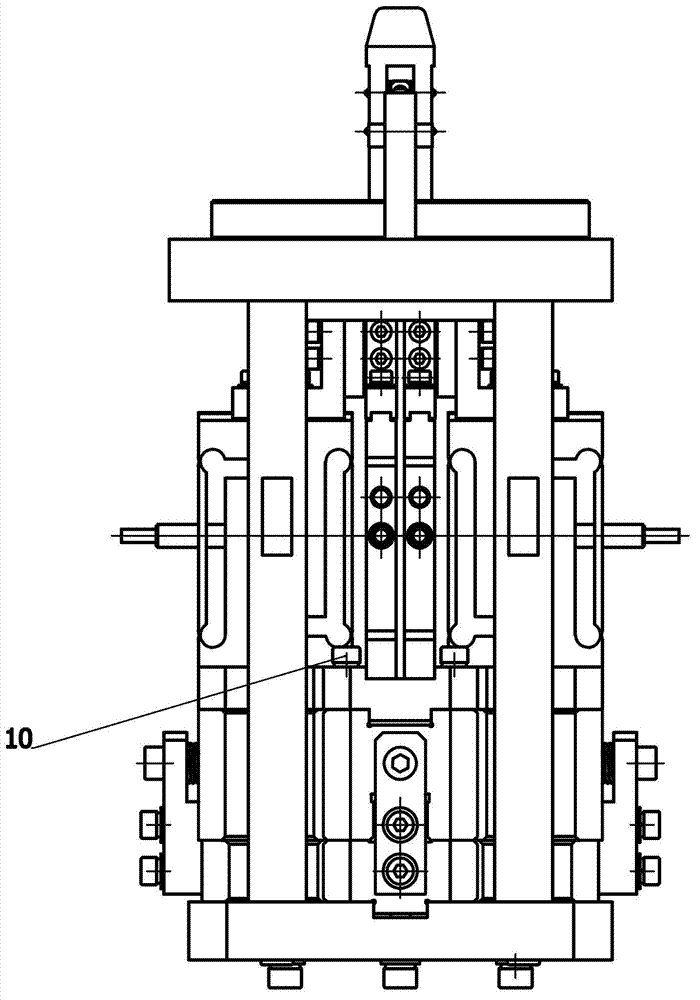

[0014] like Figure 1~3 As shown, the present invention mainly includes a positioning column 1, a first measuring head 2, a second measuring head 3, an inner measuring rod 4, an outer measuring rod 5, an upper mounting plate 7, a limit head 8, a connecting shaft 9, and a mounting block 12 , Flex gauge 13, sensor 14, fixed block 15, slide block 16, compression spring 17, adjustment screw 18, stop block 19, slide seat 20 and lower mounting plate 22.

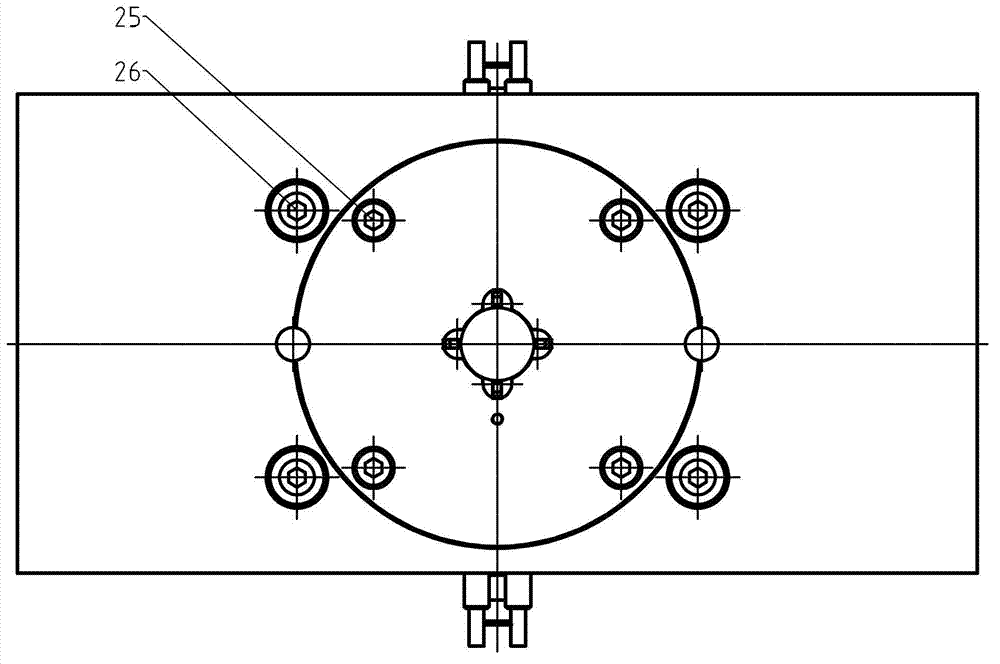

[0015] The upper mounting plate 7 and the lower mounting plate 22 are connected by four connecting shafts 9 , and the upper ends of the connecting shafts 9 are fastened on the upper mounting plate 7 by seventh screws 26 . Four sliding seats 20 are evenly distributed on the lower mounting plate 22 , and the sliding seats 20 are fastened on the lower mounting plate 22 by fifth screws 24 . A slide block 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com