High-strength antireflection film system structure

An anti-reflection film, high-strength technology, applied in the direction of optics, instruments, layered products, etc., can solve the problems of not being durable, not resistant to abrasion, and not strong enough to form a film, and achieve the effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

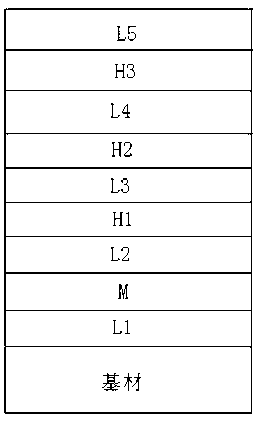

[0031] See figure 1 As shown, a high-strength anti-reflection film structure according to the present invention includes a base material S-FPL51 and an AR film plated on the base material. Among them, the AR film is an anti-reflection film, which includes a nine-layer film structure from inside to outside: the first low refractive index film (L1), the middle refractive index film (M), the second low refractive index film (L2), the first High-refractive-index film (H1), third low-refractive-index film (L3), second high-refractive-index film (H2), fourth low-refractive-index film (L4), third high-refractive-index film (H3), fifth Low refractive index film (L5).

[0032] Among them, the film material of the first low refractive index film (L1) and the medium refractive index film (M) is MgF 2 and AL 2 o 3 . The film material of the first high refractive index film (H1) is SV 7 (H 4 ). The substrate is S-FPL51 by SIO 2 , GaCO 3 、Na 2 CO 3 And inorganic compounds such a...

Embodiment 2

[0034] A high-strength anti-reflection film system structure described in the present invention comprises a base material S-BSM81 and an AR film plated on the base material. Among them, the AR film is an anti-reflection film, which includes a nine-layer film structure from inside to outside: the first low refractive index film (L1), the middle refractive index film (M), the second low refractive index film (L2), the first High-refractive-index film (H1), third low-refractive-index film (L3), second high-refractive-index film (H2), fourth low-refractive-index film (L4), third high-refractive-index film (H3), fifth Low refractive index film (L5).

[0035] Among them, the film material of the first low refractive index film (L1) and the medium refractive index film (M) is MgF 2 and AL 2 o 3 . The film material of the first high refractive index film (H1) is SV 7 (H 4 ). The base material is S-FSL5 by SIO 2 , GaCO 3 、Na 2 CO 3 And inorganic compounds such as rare earth ...

Embodiment 3

[0037]A high-strength anti-reflection film system structure described in the present invention comprises a base material LAK10 and an AR film plated on the base material. Among them, the AR film is an anti-reflection film, which includes a nine-layer film structure from the inside to the outside: the first low refractive index film (L1), the middle refractive index film (M), the second low refractive index film (L2), the first High-refractive-index film (H1), third low-refractive-index film (L3), second high-refractive-index film (H2), fourth low-refractive-index film (L4), third high-refractive-index film (H3), fifth Low refractive index film (L5).

[0038] Among them, the film material of the first low refractive index film (L1) and the medium refractive index film (M) is MgF 2 and AL 2 o 3 . The film material of the first high refractive index film (H1) is SV 7 (H 4 ). The base material is LAK10, by SIO 2 , GaCO 3 、Na 2 CO 3 And inorganic compounds such as rare e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com