A kind of catalytic cracking method of prolific gasoline

A catalytic cracking and gasoline technology, applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of high density, low cetane number, high aromatic content, etc., to reduce hydrogen consumption and improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

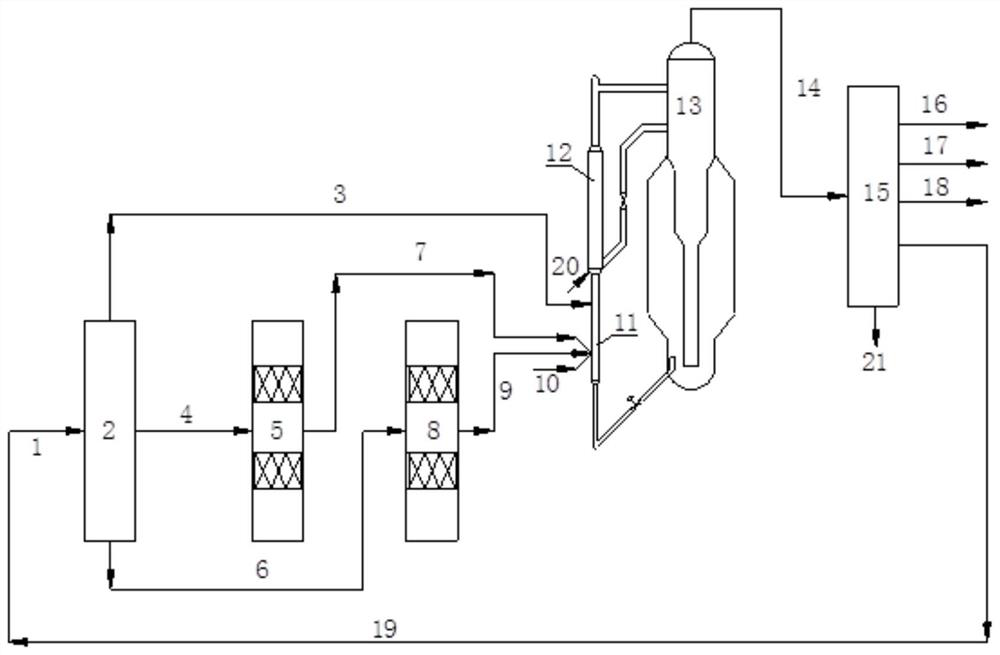

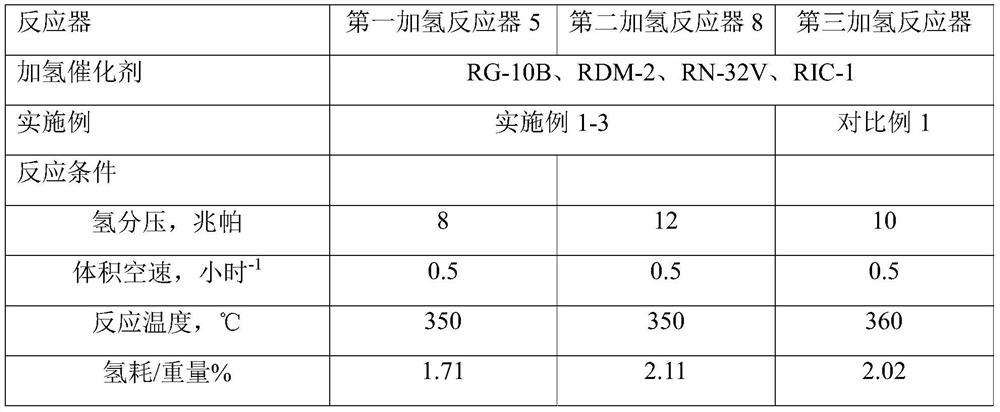

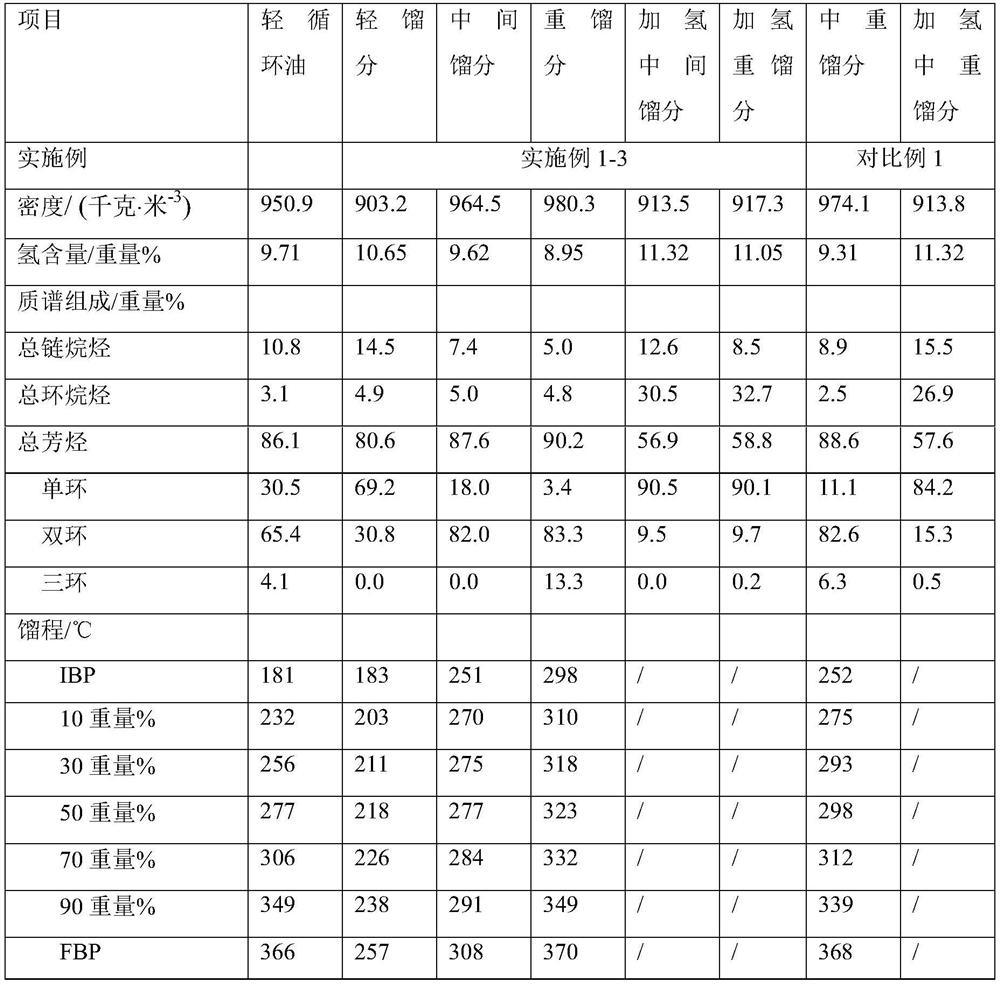

[0056] like figure 1 As shown, the catalytic cracking light cycle oil fraction first passes through the fractionation unit 2, and the light cycle oil light fraction, middle distillate and heavy fraction are obtained according to the distillation range. is 300°C. The obtained middle distillate enters the first medium-sized hydrogenation reactor 5 for the first hydrogenation treatment, and the heavy fraction enters the medium-sized second hydrogenation reactor 8 for the second hydrogenation treatment; the hydrogenation after the hydrotreatment The middle distillate, the hydrogenated heavy distillate and the catalytic cracking feed oil A from the pipeline 10 are mixed and enter the first reaction zone 11 of the riser reactor, and the light distillate enters the first reaction zone 11 of the riser reactor through the nozzle through the pipeline 3 The second reaction zone 12 at the upper end reacts under the action of catalytic cracking catalyst CGP-1, the ratio of catalytic crack...

Embodiment 2

[0058] It is basically the same as in Example 1, except that the hydrogenated heavy fraction after hydrotreating is mixed with the catalytic cracking feed oil A from the pipeline 10 and enters the first reaction zone 11 of the riser reactor, and the hydrogenation intermediate Distillates and light fractions enter the second reaction zone 12 at the upper end of the first reaction zone 11 of the riser reactor through the nozzle through the pipeline 3, and react under the action of the catalytic cracking catalyst CGP-1. The hydrogenation reaction conditions are shown in Table 3. Catalytic cracking The reaction conditions and product distribution are shown in Table 5.

Embodiment 3

[0060]It is basically the same as Example 1, except that the light distillate, the hydrogenated middle distillate after hydrotreating, and the hydrogenated heavy distillate are mixed with the catalytic cracking feedstock A at the same time and enter the first reaction zone of the riser reactor 11 and successively pass through the first reaction zone 11 and the second reaction zone 12, and react under the action of catalytic cracking catalyst CGP-1. The hydrogenation reaction conditions are shown in Table 3, and the catalytic cracking reaction conditions and product distribution are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com