Method for producing marine fuel oil

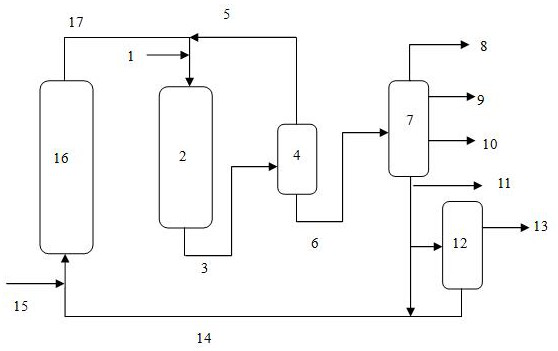

A technology for fuel oil and marine use, which is applied in the field of flexible production of low-sulfur marine fuel oil. It can solve the problems of increased difficulty in product blending, increased production costs, and improved conversion rates, and achieves improved metal capacity, low energy consumption of devices, and enhanced adaptability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The fixed bed reactor of the device adopts three sets in series, one of which is filled with two kinds of residual oil hydrogenation protection agents, and the filling volume is 12mL of FZC-12B catalyst and 45mL of FZC-103E catalyst; Catalysts, the loading volume is 60mL for FZC-28A catalyst and 165mL for FZC-204 catalyst; FZC-34A, a residual oil hydrodesulfurization catalyst, is loaded in the three reverse reactions, and the loading volume is 220mL. Catalyst properties are shown in Table 2.

[0042] The upflow reactor of the device adopts one reactor with two beds, of which the first bed is filled with 40mL of FZC-10U upflow residual oil hydrodemetallation catalyst, and the second bed is filled with FZC-11U upflow residual oil demetallization catalyst. Hydrogen desulfurization catalyst 47mL, a total of 87mL filled. Catalyst properties are shown in Table 3.

[0043] After further hydrogenation treatment, fixed bed hydrogenation reaction produces oil. The main operati...

Embodiment 2

[0047] The upflow reactor of the device adopts one reactor with two beds, of which the first bed is filled with FZC-10U upflow residual oil hydrodemetallation catalyst 170mL, and the second bed is filled with FZC-11U upflow residual oil demetallization catalyst. Hydrogen desulfurization catalyst 169mL, a total of 339mL filled. Catalyst properties are shown in Table 3.

[0048] After further hydrogenation treatment, fixed bed hydrogenation reaction produces oil. The main operating conditions are shown in Table 4, and the properties of the reaction product are shown in Table 5.

[0049] Raw material A is mixed with the effluent of the upflow hydrogenation reactor and circulating hydrogen, and then undergoes hydrogenation treatment in a fixed bed hydrogenation reactor, and then undergoes gas-liquid separation to obtain gas-phase products and liquid-phase products, wherein the liquid-phase products are subjected to atmospheric fractionation to obtain fuel gas , hydrogenated naph...

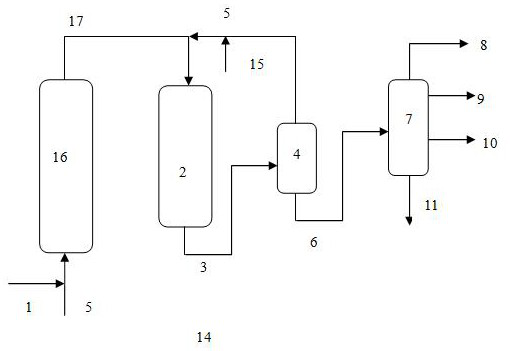

Embodiment 3

This comparative example adopts the process route of upflow type and fixed bed reactor series (see figure 2 ), that is, the residual oil raw material is first hydrogenated in the upflow reactor, and then enters the fixed bed reactor for hydrogenation reaction, and the hydrogenated oil is fractionated to obtain fuel gas, hydrogenated naphtha, hydrogenated diesel and hydrogenated Atmospheric residue. Hydrogenated atmospheric residual oil is used as a low-sulfur marine fuel product.

[0054] The upflow reactor of the device adopts one reactor with two beds, of which the first bed is filled with 80mL FZC-10U upflow residual oil hydrodemetallation catalyst, and the second bed is filled with FZC-11U upflow residual oil demetallization catalyst. Hydrogen desulfurization catalyst 89mL, a total of 169mL filled. Catalyst properties are shown in Table 3.

[0055] The fixed-bed reactor of the device adopts three sets in series, one of which is filled with three kinds of residual oil hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com