Unirersal technology for preparing nano-powder

A nano-powder, general-purpose technology, applied in grain processing, blasting, etc., can solve problems such as application limitations, and achieve the effect of small experimental scale, simple and fast process, and good powder quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10g of metallic aluminum powder and 90g of TNT (with 5% nitrobenzene added) were uniformly mixed. Die-cast into a column at 20Gpa, put it into a closed cylindrical explosion tank filled with nitrogen, use an electric detonator to detonate, collect the explosion products after the explosion, filter out the impurities with a sieve, and calcinate the obtained solid at 700°C for 2 hour, can obtain 14g off-white nano-aluminum nitride powder without grinding, and the yield is 140%.

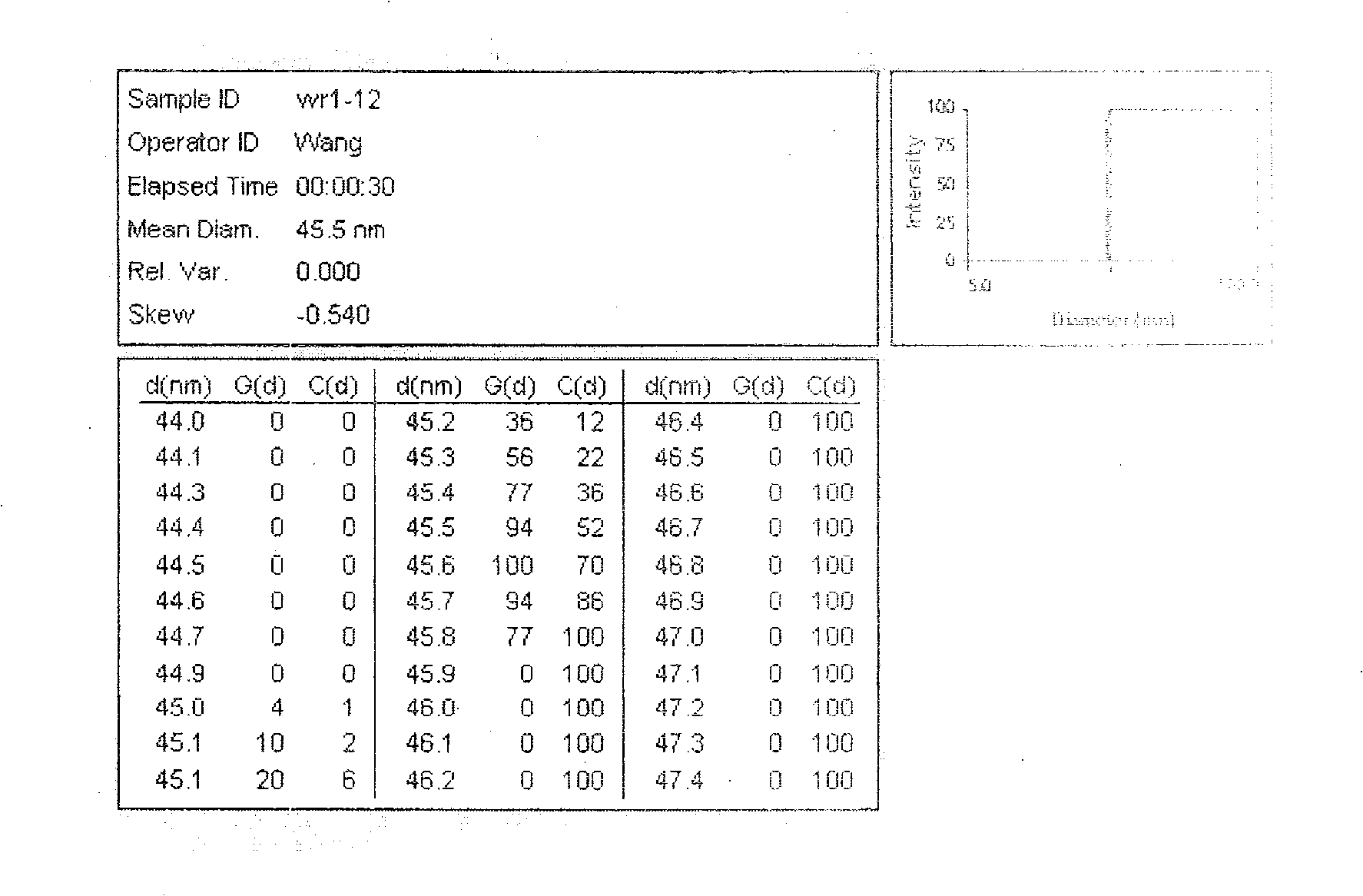

[0021] The particle size analysis results can be found in the appendix figure 1 , the average particle size is 45.5nm, and the particle size distribution is ±0.35nm;

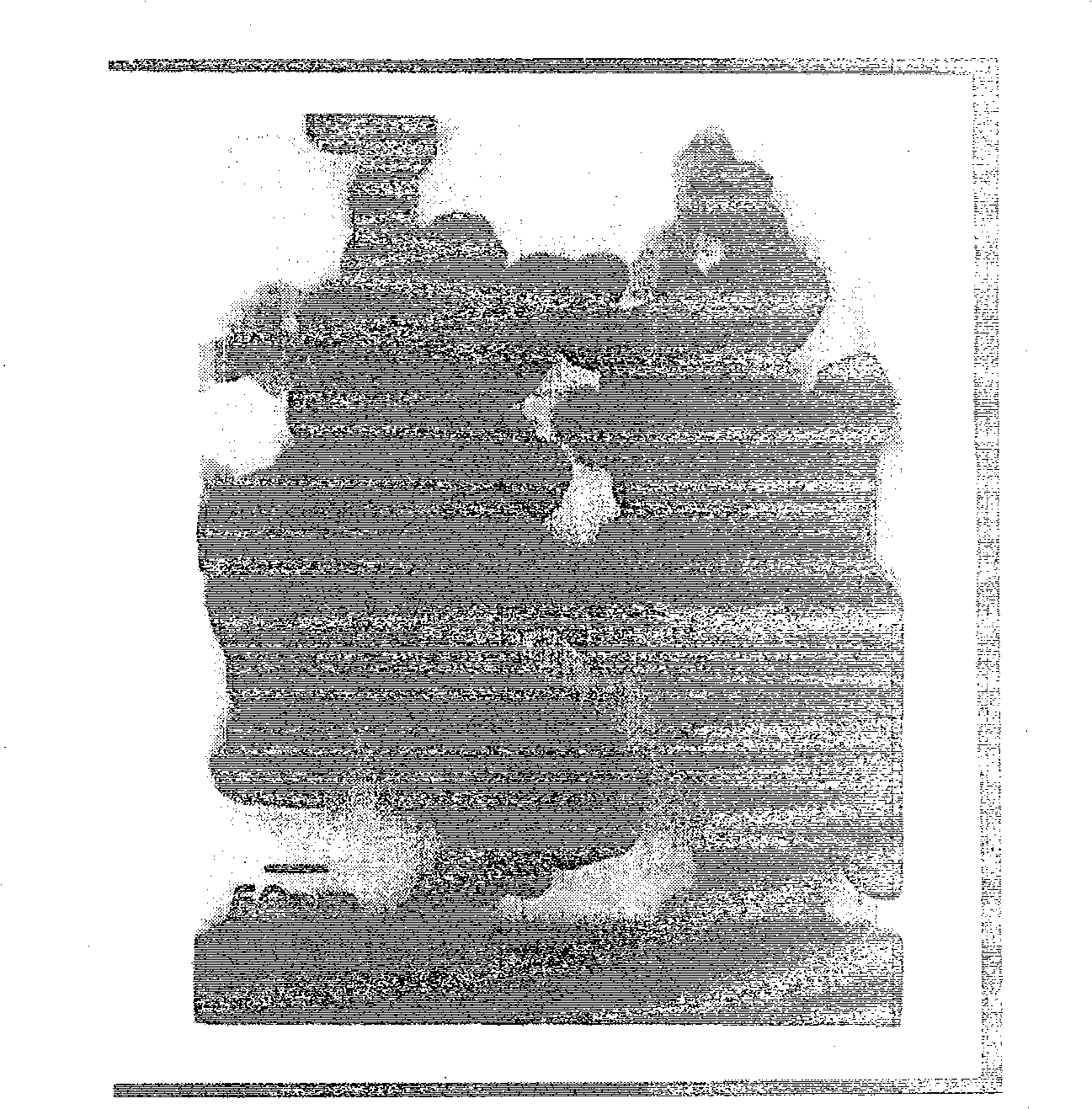

[0022] TEM see attached figure 2 , the particles are cubic, with good dispersion and no obvious agglomeration;

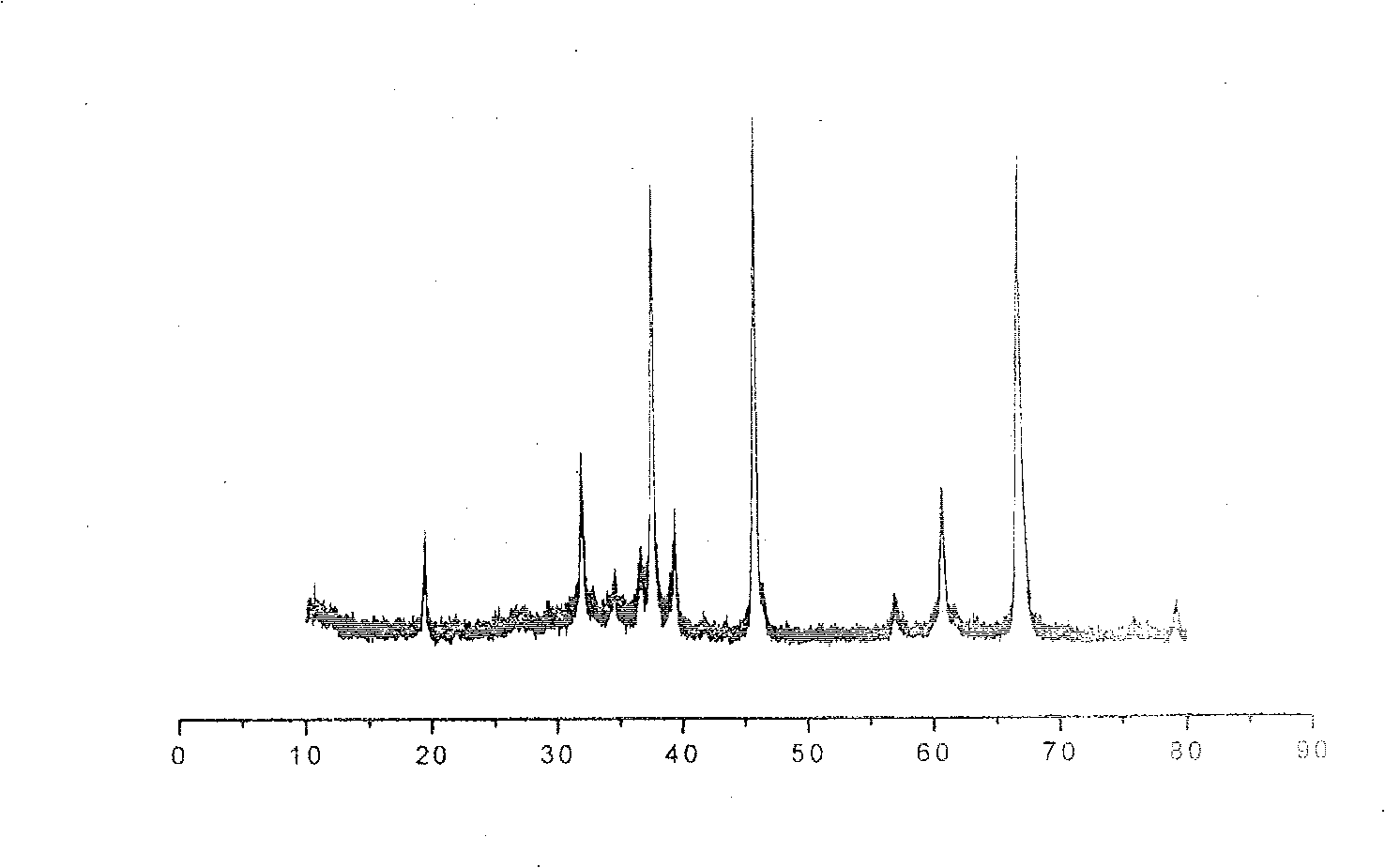

[0023] The results of X-ray diffraction analysis are shown in the appendix image 3 , the diffraction angles 2θ of the main absorption peaks are 31.82°, 37.50°, 45.67°, 60.5°, 66.62°, which are completely consistent...

Embodiment 2

[0025] Mix 10g metal iron powder and 90g TNT / RDX (80 / 20) mixed explosive evenly, die-cast it into a concave table at 30Gpa, put it into a closed cylindrical explosion tank filled with water, use an electric detonator to detonate, and collect after explosion Explosion product, use a sieve to filter out impurities, centrifuge, and calcinate the obtained solid at 700°C for 2 hours to obtain 12 red nano-iron oxide powders without grinding, with a yield of 120% and a particle size of 40.3nm , X-ray diffraction analysis showed that it was pure α phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com