Production scheduling method based on production process decoupling point positioning

A production process and production scheduling technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of neglecting the improvement of the scheduling model, and the decoupling point of the production process has not been mentioned in the literature, and achieves the speed of operation. Fast, accurate and effective solution results, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

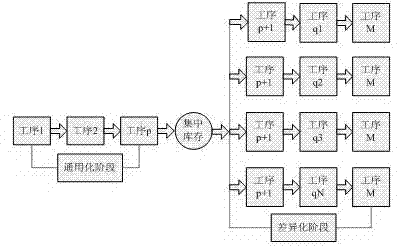

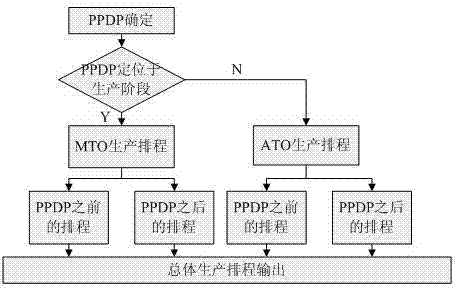

[0025] The following is a systematic detailed description of the production scheduling method based on the location of decoupling points in the PPDP production process.

[0026] 1. The premise of system production scheduling.

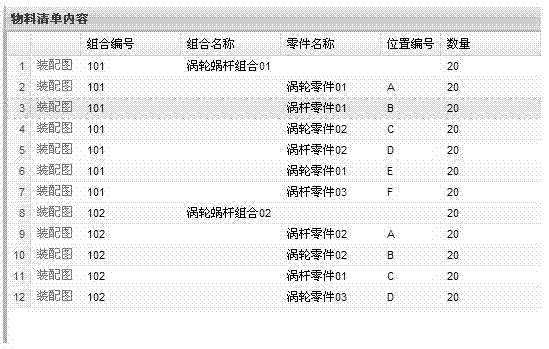

[0027] as attached image 3 , the front-end input of the production schedule is the self-made part BOM table, which gives information such as the name and quantity of the self-made part, as well as the production data of the self-made part such as the process card, that is, the content of the bill of material in the system.

[0028] 2. Set up the production process.

[0029] as attached Figure 4 ,, in the production process, fill in all the production processes required in the order production schedule, as well as the processing equipment required for each process and the time required for single-piece processing.

[0030] 3. Set up the part process.

[0031] as attached Figure 5 , select different processing parts from the smallest component, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com