A correlation method of steel coil length technology

A steel coil and process technology, applied in the intersection of steel production control and information technology, can solve problems such as the inability to share results, affecting the accuracy of the calculation of the total length of the steel coil, and failing to meet the rapid determination and analysis of production quality conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

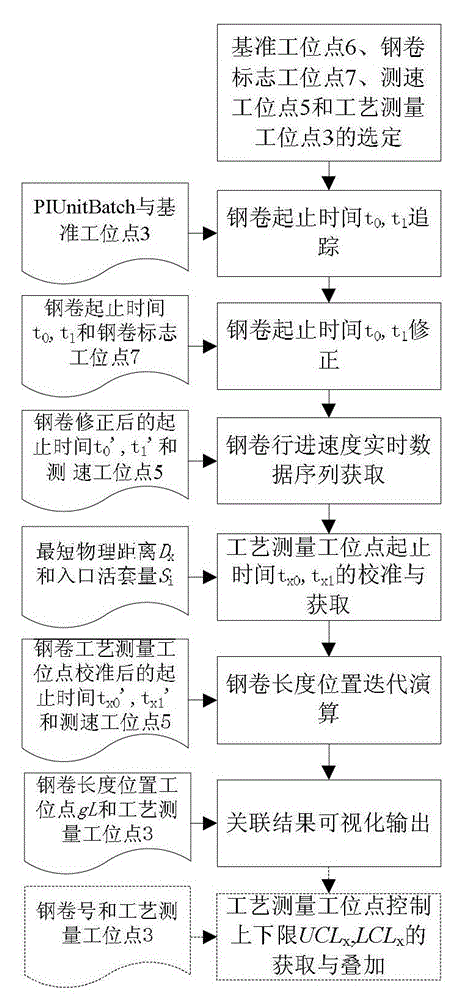

[0086] A kind of association method of steel coil length technology, described association method is as figure 2 Shown:

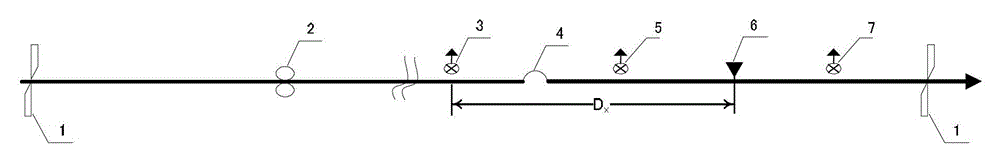

[0087] Step 1, such as figure 1 As shown in Fig. 1, the reference station point 6, the steel coil mark station point 7, the speed measurement station point 5 and the process measurement station point 3 are first selected for the hot rolling mill, and then the coil length position station point is established by using PISMT, and then A sensor for collecting the steel coil number and a sensor for collecting the production mark of the steel coil are correspondingly arranged at the reference station point 6, the steel coil mark station point 7, the speed measurement station point 5 and the process measurement station point 3 in turn. , A sensor for collecting the speed of the steel coil and a sensor for collecting the surface quality of the steel coil.

[0088] Step 2, use PIUnitBatch and reference station point 6 to track the steel coil, and obtain the steel ...

Embodiment 2

[0147] A kind of association method of steel coil length technology, described association method is as figure 2 Shown:

[0148] Step one, such as figure 1 As shown in the figure, first select the reference station point 6, the steel coil mark station point 7, the speed measurement station point 5 and the process measurement station point 3 for the cold rolling mill, and then use PISMT to establish the steel coil length position station point, and then A sensor for collecting the steel coil number and a sensor for collecting the production mark of the steel coil are correspondingly arranged at the reference station point 6, the steel coil mark station point 7, the speed measurement station point 5 and the process measurement station point 3 in turn. , A sensor for collecting the speed of the steel coil and a sensor for collecting the surface quality of the steel coil.

[0149] Step 2, use PIUnitBatch and reference station point 6 to track the steel coil, obtain the steel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com