Method for Improving the Uniformity of Polysilicon Doping and Diffusion in SiGe Emitter

A technology of polysilicon and emitter, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven diffusion, unstable diffusion junction depth, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0011] In this embodiment, the diffusion uniformity after polysilicon doping of the SiGe emitter is improved through the following process steps:

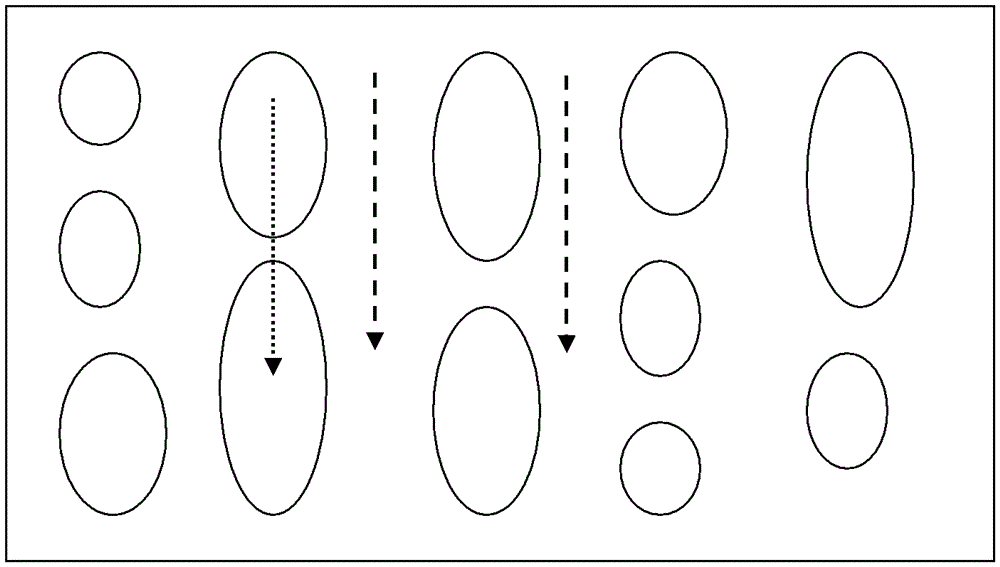

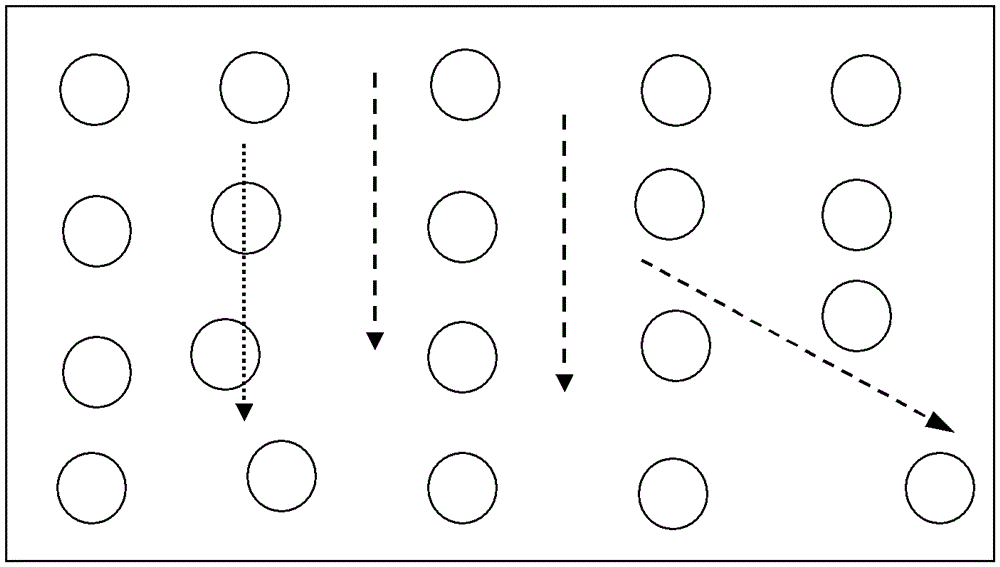

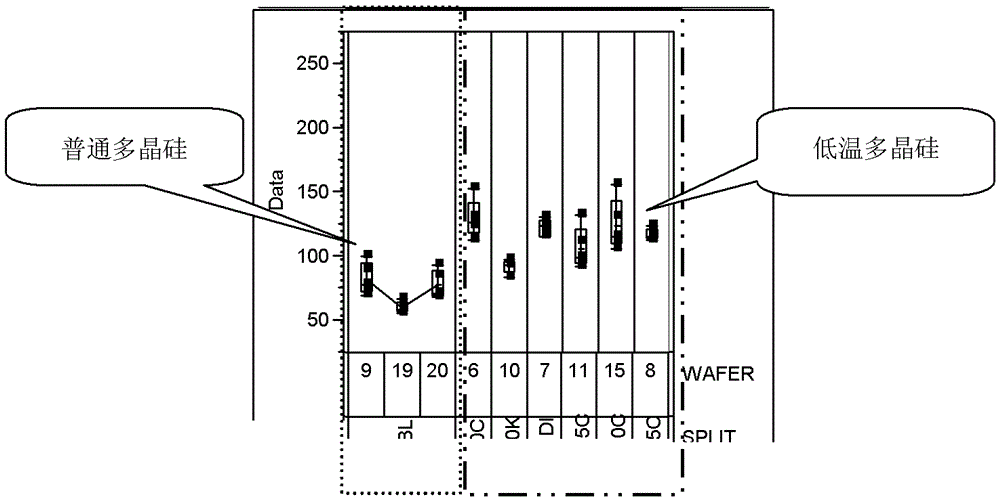

[0012] Firstly, when polysilicon is deposited by low-pressure chemical vapor deposition in the furnace tube, the average temperature of the furnace tube is set at a low temperature of 590-620° C., and the pressure is set at 300-800 mTorr. In the polysilicon film layer formed after such deposition, the grain size is small and uniform. After doping, the diffusion of impurities is mainly completed through the grain boundary, such as figure 2 As shown, since impurities diffuse less through the crystal grains, the diffusion speed of impurities in polysilicon is basically the same, so that a more stable EB junction depth and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com