Indium Phosphide Diffusion Method

A diffusion method and indium phosphide technology, applied in the field of indium phosphide diffusion, can solve the problems of surface crystal quality degradation, slow diffusion speed, difficult control, etc., and achieve the effects of improving diffusion uniformity, ensuring yield, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

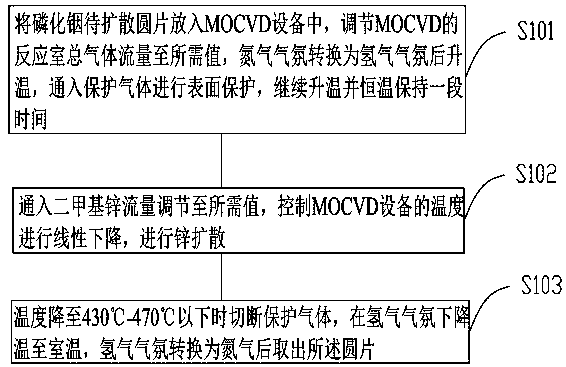

[0031] The invention discloses an indium phosphide diffusion method, comprising the following steps:

[0032] S201: Put the indium phosphide wafer to be diffused into the MOCVD equipment, adjust the total gas flow rate of the reaction chamber to 20000-50000sccm, the pressure of the reaction chamber to 50-500mbar, change the nitrogen atmosphere to a hydrogen atmosphere and then raise the temperature. After the temperature rises to 470°C, the Put in phosphine for surface protection, the flow rate of phosphine is 500 sccm, continue to raise the temperature to 600°C, and keep the constant temperature for 3 minutes.

[0033] S202: feed dimethyl zinc, the flow rate of dimethyl zinc is 200 sccm, control the temperature to decrease linearly from 600° C. to 500° C., and carry out zinc diffusion.

[0034] S203: Cool down naturally, cut off the phosphine protection when the temperature drops below 470°C, cool down to room temperature in the hydrogen atmosphere, and take out the wafer aft...

Embodiment 2

[0036] The invention discloses an indium phosphide diffusion method, comprising the following steps:

[0037] S301: Put the indium phosphide wafer to be diffused into the MOCVD equipment, adjust the total gas flow rate of the reaction chamber to 20000-50000sccm, and the pressure of the reaction chamber to 50-500mbar, change the nitrogen atmosphere to a hydrogen atmosphere and then raise the temperature. After the temperature rises to 450°C, turn on Put in phosphine for surface protection, the flow rate of phosphine is 250sccm, continue to raise the temperature to 580°C, and keep the constant temperature for 2min.

[0038] S302: feed dimethyl zinc, the flow rate of dimethyl zinc is 100 sccm, control the temperature to decrease linearly from 580° C. to 500° C., and carry out zinc diffusion.

[0039] S303: Cool down naturally, cut off the phosphine protection when the temperature drops below 450°C, cool down to room temperature in the hydrogen atmosphere, and take out the wafer a...

Embodiment 3

[0041] The invention discloses an indium phosphide diffusion method, comprising the following steps:

[0042] S401: Put the indium phosphide wafer to be diffused into the MOCVD equipment, adjust the total gas flow rate of the reaction chamber to 20000-50000sccm, the pressure of the reaction chamber to 50-500mbar, change the nitrogen atmosphere to a hydrogen atmosphere and then raise the temperature. After the temperature rises to 430°C, the Put in phosphine for surface protection, the flow rate of phosphine is 50sccm, continue to raise the temperature to 560°C, and keep the constant temperature for 1.5min.

[0043] S402: feed dimethyl zinc, the flow rate of dimethyl zinc is 20 sccm, control the temperature to decrease linearly from 560° C. to 500° C., and carry out zinc diffusion.

[0044] S403: Cool down naturally, cut off the phosphine protection when the temperature drops below 430°C, cool down to room temperature in the hydrogen atmosphere, and take out the wafer after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com