Method and device for preparing methanol using isothermal catalytic bed

A catalytic bed, methanol technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve precise control, reduce the risk of hot spots or overheating, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

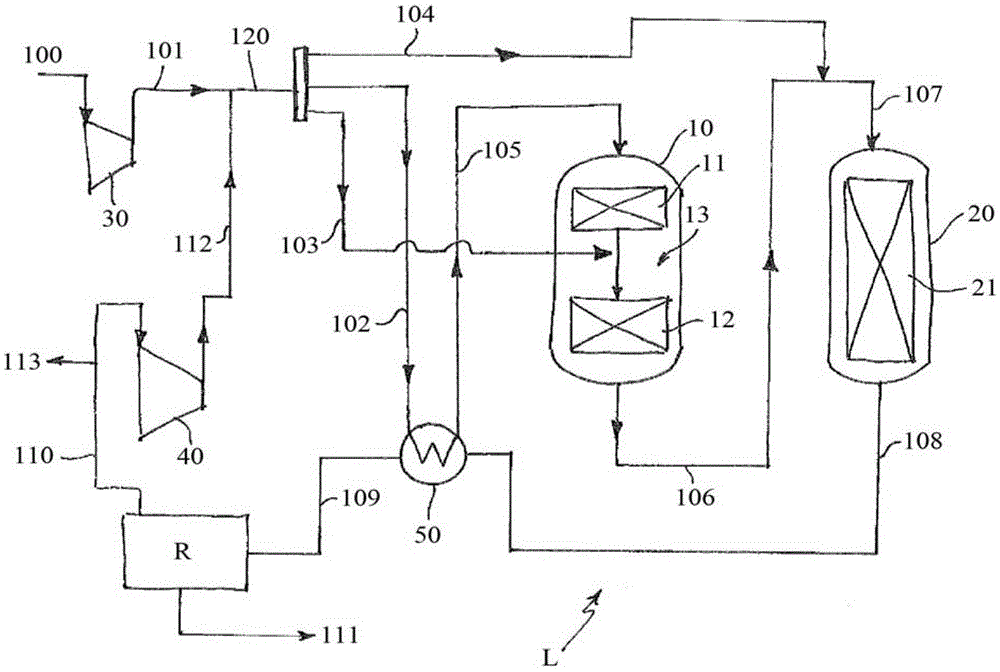

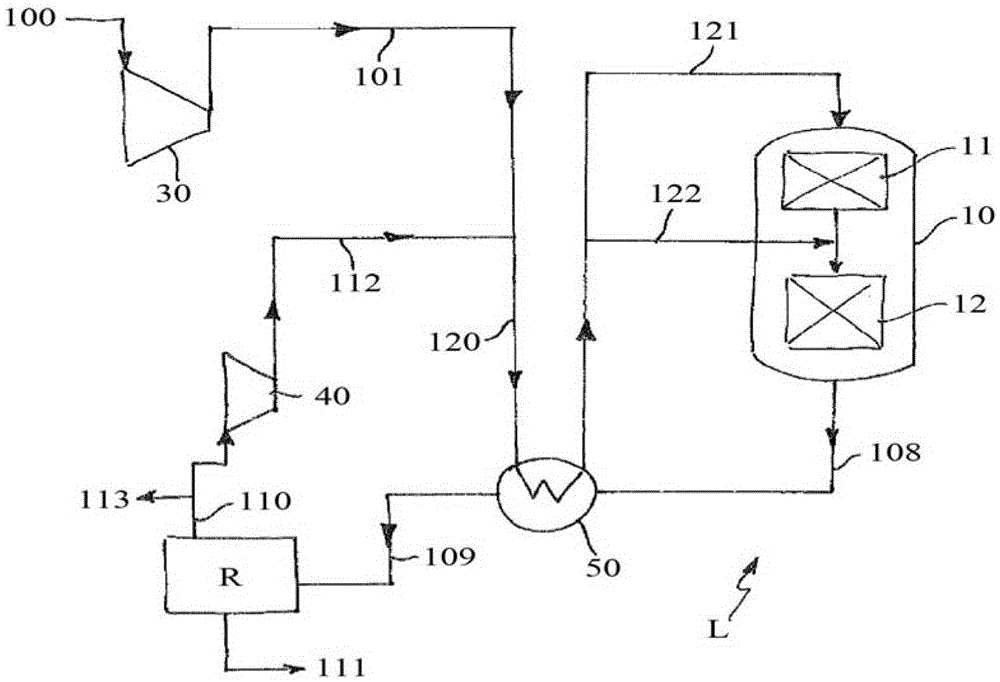

[0033] refer to figure 1 , the methanol synthesis loop L comprises three isothermal catalytic beds arranged in two reactors. Reactor 10 contains two catalytic beds 11 and 12 , while the other reactor 20 contains a third catalytic bed 21 .

[0034] The supplementary gas 100 is compressed in the main compression section 30 to obtain a compressed gas feed 101 , which is mixed as feed with a cycle gas 112 downstream of said compression section 30 . The mixture 120 of fresh gas 101 and cycle gas 112 is divided into three fractions 102 , 103 and 104 .

[0035] The first portion 102 forms the feed gas 105 for the first catalytic bed 11 after preheating in the gas effluent heat exchanger 50 . In the space 13 located inside the reactor 10 and between the catalytic bed 11 and the catalytic bed 12 , the second portion 103 is mixed with the effluent of said catalytic bed 11 . Thus, the second section 103 quenches the effluent of the first bed 11 and assists in controlling the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com