Anomaly diagnostic device and industrial machine

A diagnostic device and abnormal diagnosis technology, applied in the direction of registering/instructing the work of machines, instruments, electrical testing/monitoring, etc., can solve problems such as the impact of maintenance work efficiency on diagnostic processing performance, difficulty in setting diagnostic processing benchmark values, etc., to reduce Effects of communication capacity, improved diagnostic accuracy, and reduced communication data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0040] refer to Figure 1 to Figure 5 The first embodiment of the present invention will be described.

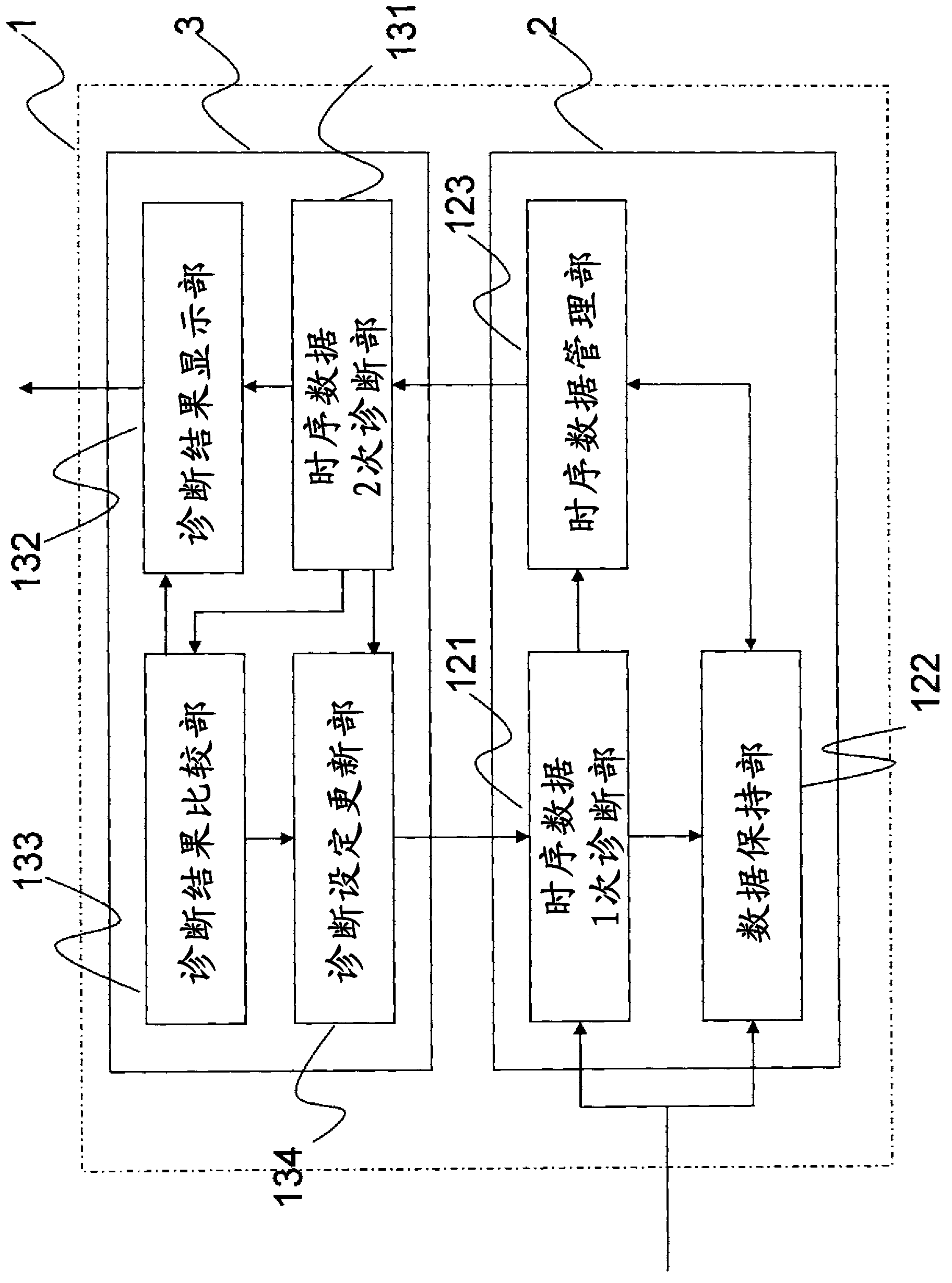

[0041] figure 1It is a figure which shows the structure of the abnormality diagnosis apparatus of this invention. The abnormality diagnosis device 1 is composed of a machine side diagnosis device 2 (first diagnosis device) installed in a machine side computer and a server side diagnosis device 3 (second diagnosis device) installed in a server. The machine-side diagnosis device 2 is composed of a time-series data primary diagnosis unit 121 (first time-series data diagnosis unit), a data storage unit 122 , and a time-series data management unit 123 . The server-side diagnosis device 3 is composed of a time-series data secondary diagnosis unit 131 (second time-series data diagnosis unit), a diagnosis result display unit 132 , a diagnosis result comparison unit 133 , and a diagnosis setting update unit 134 .

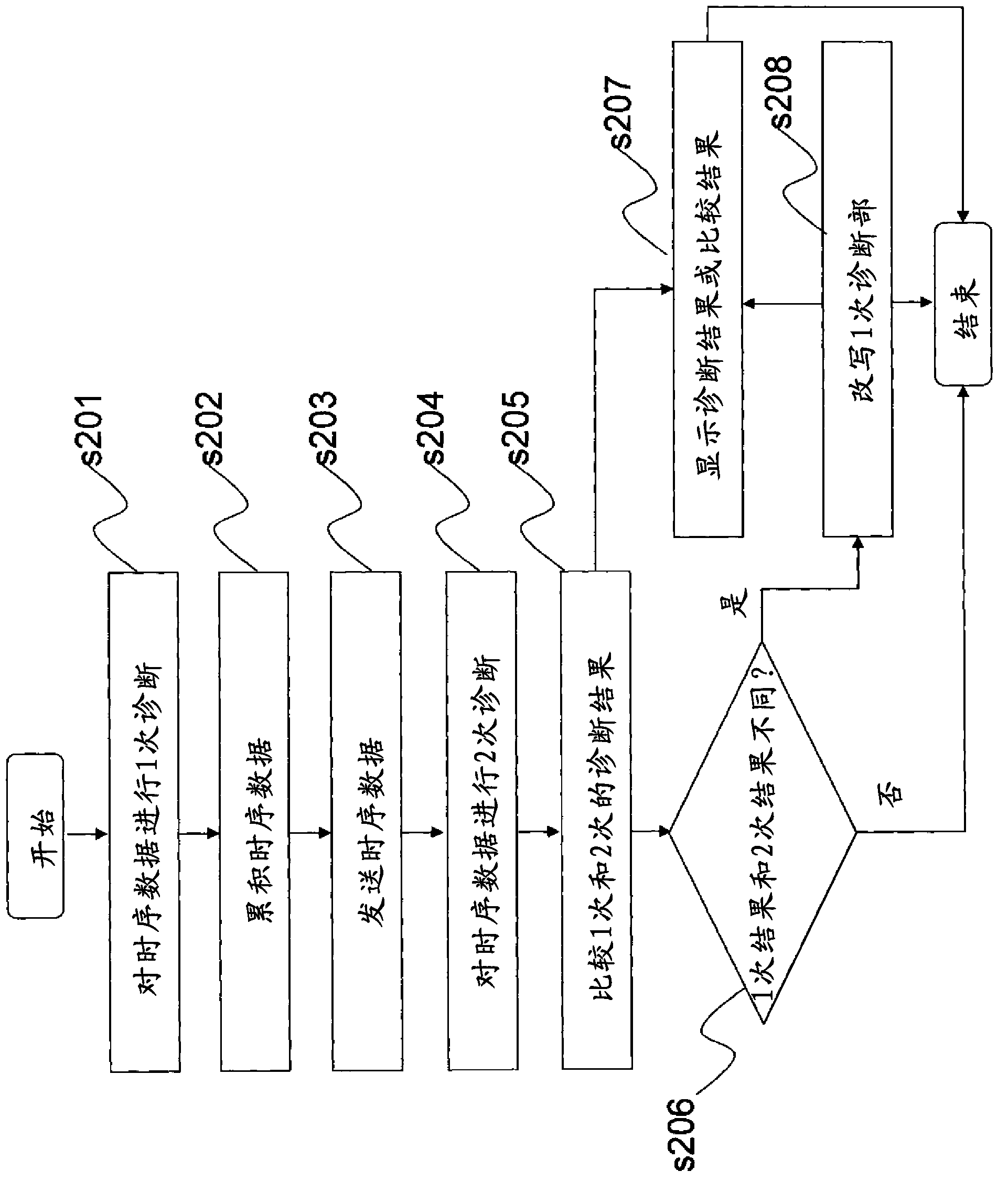

[0042] figure 2 It is a flowchart showing the functions and ope...

no. 2 Embodiment approach

[0062] use Figure 7 and the previous figure 1 , figure 2 as well as Figure 4 A second embodiment of the present invention will be described. figure 1 as well as figure 2 The configuration, functions, and operations of the abnormality diagnosis device 1 according to the present invention shown are the same as those described in the first embodiment, and thus are omitted.

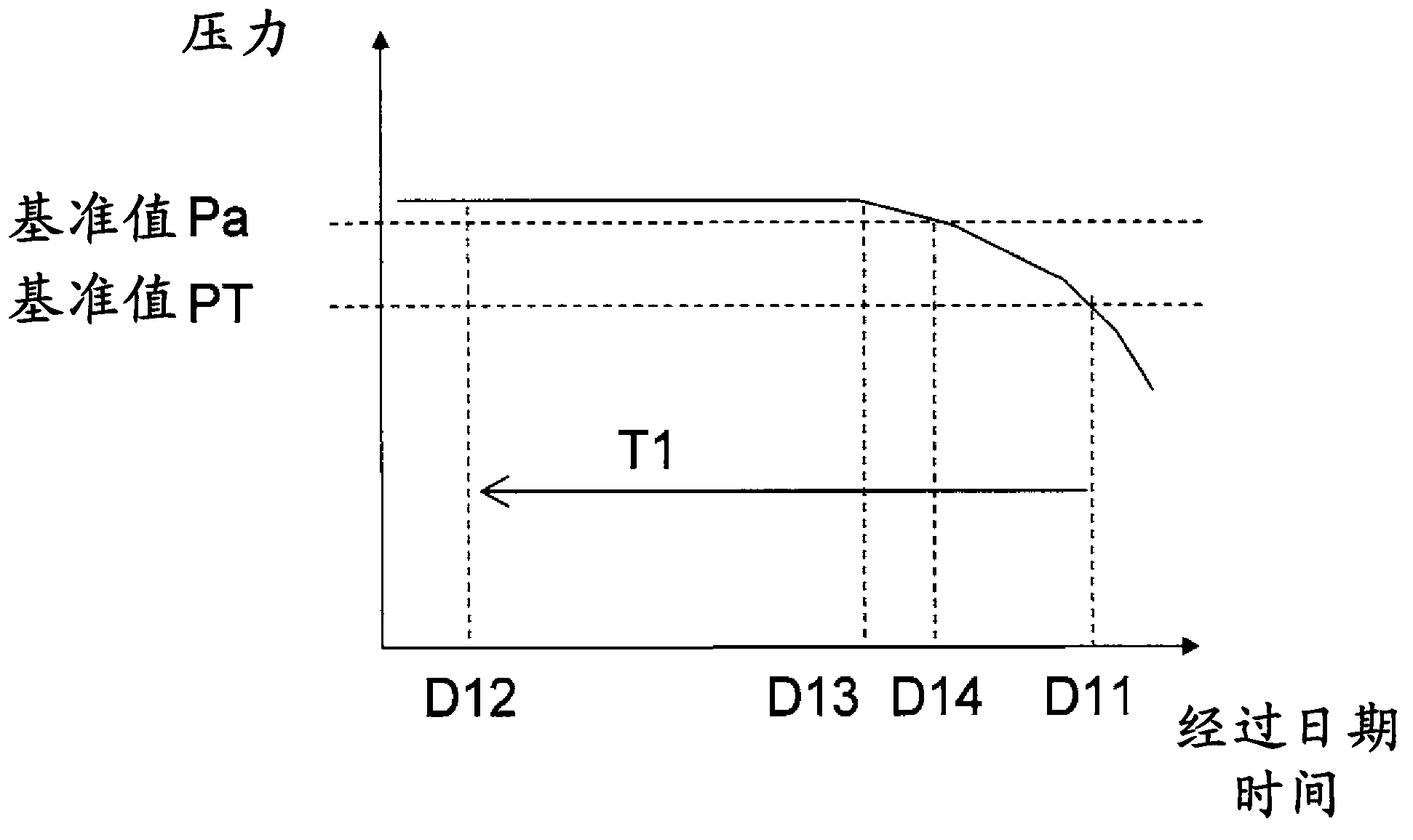

[0063] Details of the functions and operations of this embodiment will be described below. Figure 7 It is the data obtained by digitizing the signal obtained by the abnormality diagnosis device 1 from a sensor mounted on a device (not shown) as the diagnostic target, that is, the time-series data 401 of the pressure sensor value and the signal indicating the activation state of the device 402 diagram of the timing data. It shows that the start and stop are repeated over time, and the pressure sensor value also fluctuates with the start and stop. In this embodiment, an abnormality occurs in the equ...

no. 3 Embodiment approach

[0071] Next, use Figure 8 An application example of the abnormality diagnosis device of the present invention will be described. Figure 8 It is a figure which shows the whole structure of the large hydraulic excavator which is an example of the industrial machine to which the abnormality diagnosis apparatus of this invention is applied, and an abnormality diagnosis apparatus.

[0072] The large-scale hydraulic shovel 8 can perform actions such as excavation through various operating mechanisms provided. Bucket 801 , arm 802 , and boom 803 constitute a work machine, and these are driven by hydraulic cylinders 811 , 812 , and 813 . In addition, the hydraulic shovel 8 includes a revolving body 806 , a revolving mechanism 804 for rotating the revolving body 806 , and left and right crawler devices 805 (only one side shown in the figure) as traveling mechanisms of the hydraulic shovel as a whole. The swivel mechanism 804 includes a hydraulic motor (not shown) for swiveling, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com