Production technology for mung bean sprouts

A production process and technology of mung bean sprouts, which are applied in food preparation, food science, and preservation of fruits/vegetables by freezing/refrigeration, etc., can solve the problems of high labor intensity, low efficiency, and inability to produce mung bean sprouts normally, and achieve the improvement of rationalization, Reduce the effect of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

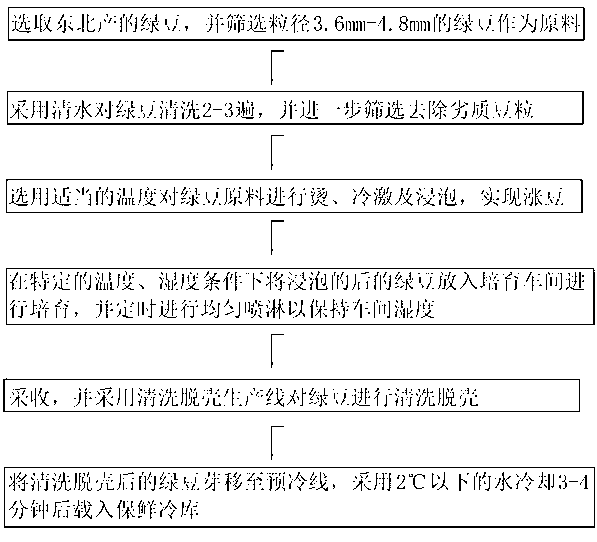

Method used

Image

Examples

Embodiment 1

[0026] Select mung beans from the land at the junction of Inner Mongolia, Heilongjiang and Jilin, and screen for more than three times to obtain mung beans with a diameter of about 3.6mm; wash the mung beans with clean water 2-3 times, and remove moth-eaten, broken, deformed, mildewed, sprouted, For immature granules, wash the sediment and remove impurities; then blanch the beans with hot water at 75°C for 1min-3min and keep stirring to sterilize them, then pour them into cold water to quench them, soak them in clean water at 20°C for 3 hours to grow the beans, The amount of soaking water is twice the weight of the raw mung beans; after soaking the beans, wash them 2-3 times, rub, rinse, rinse off the mucus on the surface of the mung beans and remove the rotten beans, and then germinate them at 28°C for 3-4 hours; The mung beans soaked and germinated are transported to the cultivation workshop and placed in cultivation tanks for 6 days of dark cultivation. The weight of mung be...

Embodiment 2

[0028] Select mung beans from the land at the junction of Inner Mongolia, Heilongjiang and Jilin, and screen more than three times to obtain mung beans with a diameter of about 4.2mm; wash mung beans with clean water 2-3 times, and remove moth-eaten, broken, deformed, mildewed, sprouted, For immature granules, wash the sediment and remove impurities; blanch the beans in hot water at 78°C for 2 minutes without stopping to sterilize them, then pour them into cold water to quench them, and soak them in clean water at 22°C for 3.5 hours to grow the beans, the amount of soaking water The weight of mung beans is twice the weight of the raw material; wash the beans 2-3 times after soaking, rub, rinse, rinse off the mucus on the surface of the mung beans and remove the rotten beans, and then germinate them at 28°C for 3-4 hours; soak the beans together The mung beans after germination are transported to the cultivation workshop and put into cultivation tanks for 6-7 days of dark cultiv...

Embodiment 3

[0030]Select mung beans from the land at the junction of Inner Mongolia, Heilongjiang and Jilin, and screen more than three times to obtain mung beans with a diameter of less than 4.8mm; wash mung beans with clean water 2-3 times, and remove moth-eaten, broken, deformed, mildewed, sprouted, For immature granules, wash the sediment and remove impurities; blanch the beans in hot water at 80°C for 1 minute and stir continuously to sterilize them, then plunge them into cold water to quench them, soak them in clean water at 25°C for 3 hours to grow the beans, and soak the beans in water The weight of the raw mung beans is twice the weight; after soaking the beans, wash them 2-3 times, rub, rinse, rinse off the mucus on the surface of the mung beans and remove the rotten beans, and then germinate them at 28°C for 3-4 hours; The mung beans soaked and germinated are transported to the cultivation workshop and put into cultivation tanks for 6-7 days of dark cultivation. The weight of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com