Sediment concentration coil pipe

A sediment and spiral technology, which is applied in the field of solid-liquid mixed fluid separation, can solve the problems of high moisture content of dredged silt slurry and long time required for free settlement, etc., and achieve small local head loss, simple structure and small flow resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

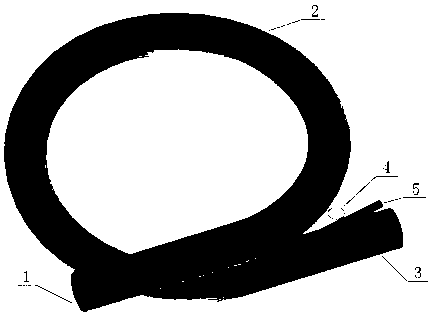

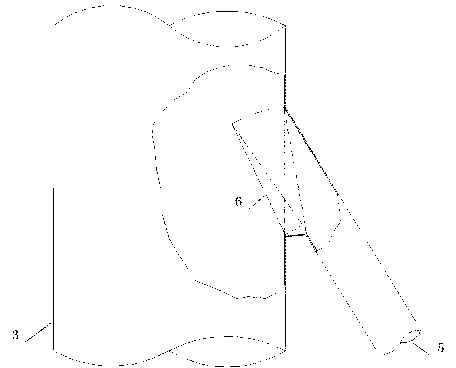

[0012] Example 1: The upper and lower ends of the sediment concentration coil are the upper circular pipe inflow section 1 and the lower circular pipe outflow section 3 respectively, and the middle spiral pipe section 2 is two or more semicircular curved pipes connected by spiral descending.

[0013] The diameter of the spiral pipe 2 should be consistent with the pipe diameter of the outlet and inlet ends.

[0014] The radius of the longitudinal axis of the curved pipe that forms the spiral pipe 2 and the angle between the horizontal plane and the spiral descent after connection are designed according to the actual situation and separation requirements.

[0015] After the mud-water mixture enters the spiral pipe 2, it will form a three-dimensional spiral flow, and the sediment with higher density will be thrown to the outside of the pipe away from the center of the arc section, so that the sediment concentration on the outer side of the outflow section 3 will be higher, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com