Internal high pressure forming sealing device

An internal high pressure forming and sealing device technology, applied in the field of internal high pressure forming of metal materials, can solve the problem of high forming pressure, achieve the effects of stabilizing forming quality, reducing external dimensions and forming maximum pressure, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the drawings and specific examples.

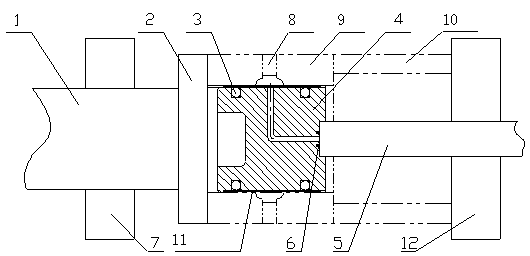

[0021] Such as figure 1 As shown, it is a structural schematic diagram of a sealing device for internal high pressure forming of the present invention. The device includes: a propulsion cylinder 1, a flange 2, a sealing ring 3, a water injection die head 4, a stepping cylinder 5, a sealing ring 6, and a frame 7.

[0022] The propulsion cylinder 1 is connected with the control system, and the control system controls the advance and retreat of the propulsion cylinder to realize the clamping of the diaphragm and the gasket; the flange 2 and the propulsion cylinder 1 are fastened by bolts; the water injection die head 4 and the step The inlet cylinders 5 are connected and fastened by bolts, and the water injection die head 4 and the step cylinder 5 are sealed by a sealing ring 6 to prevent leakage of high-pressure liquid; the step cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com