Directly heating machine

A direct heat engine and evaporator technology, applied in the field of heat exchange, can solve the problems that medium and high temperature wastewater heat exchangers cannot be used, and cannot be solved well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

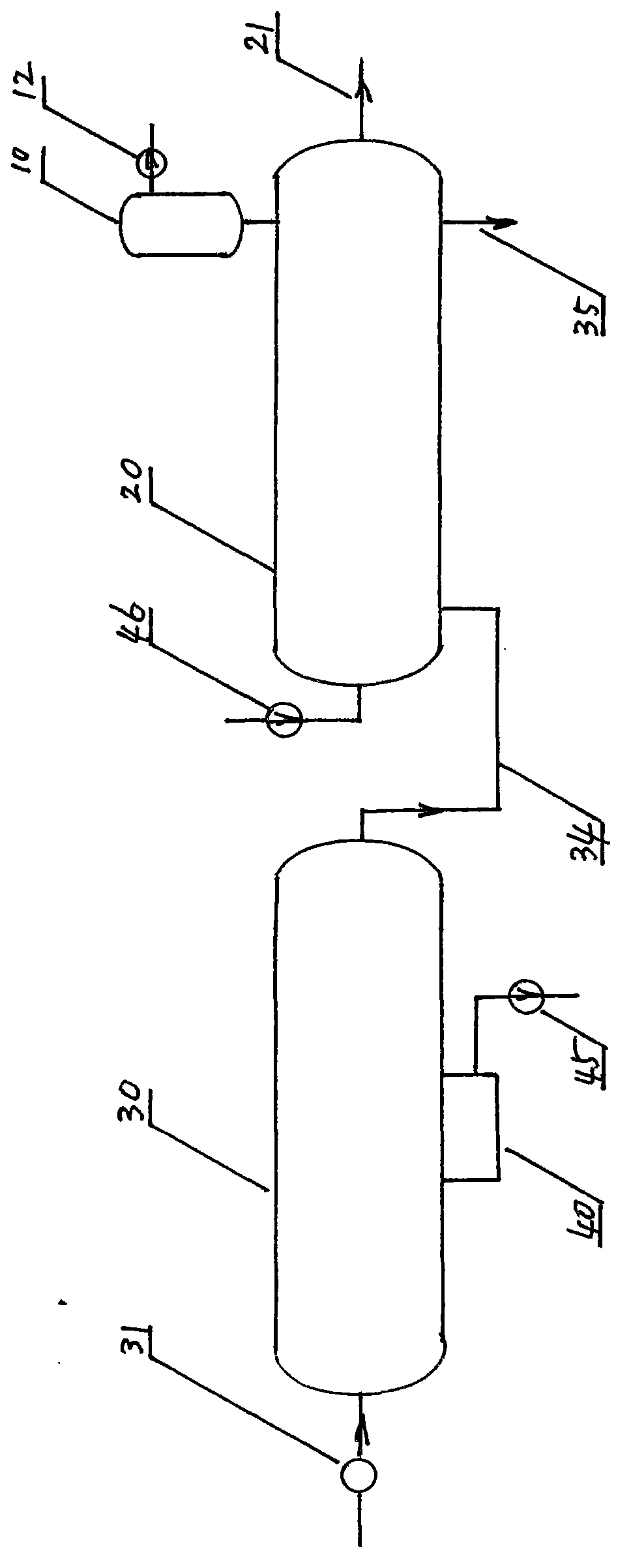

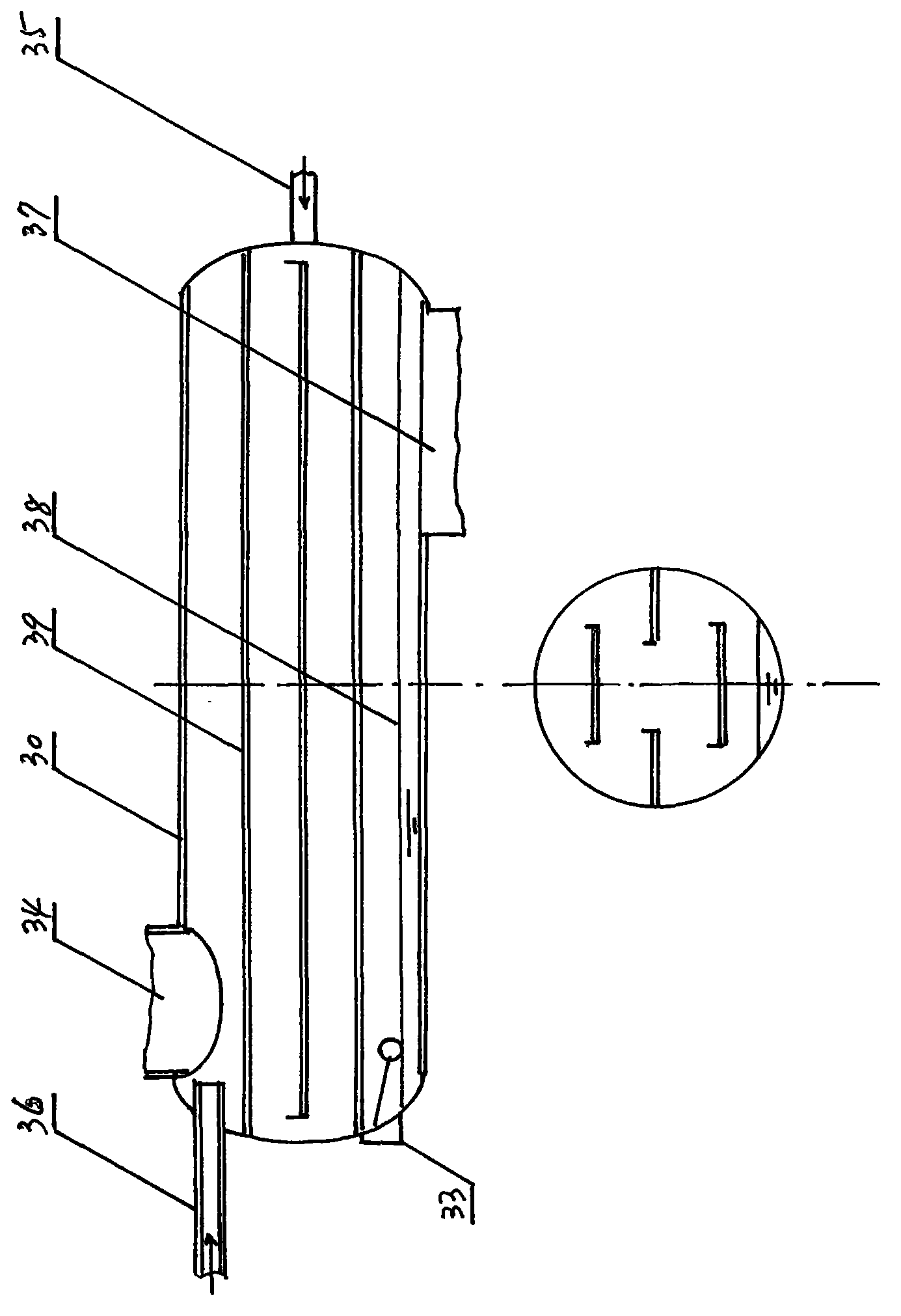

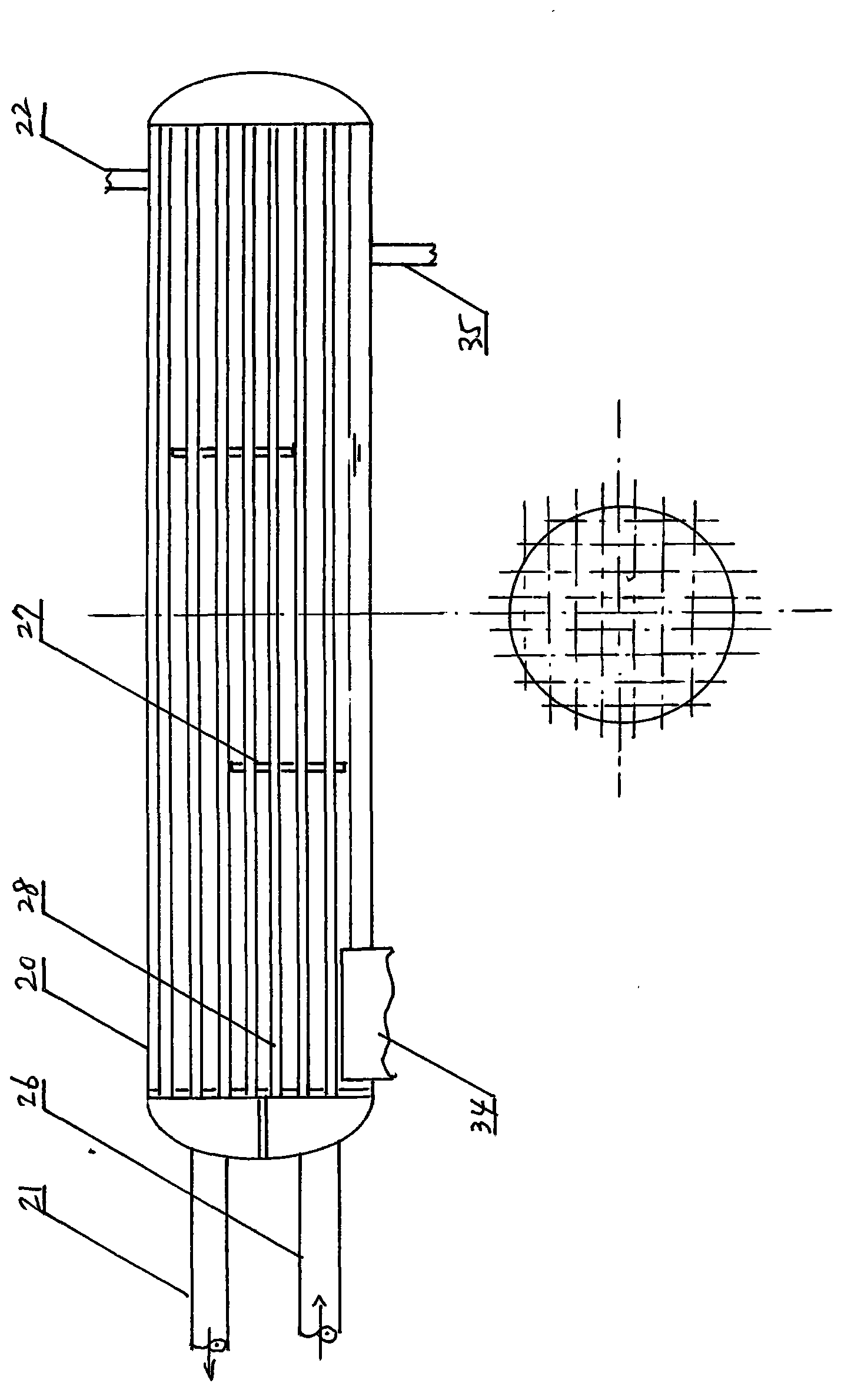

[0030] figure 1 The system diagram of the direct heat engine embodiment of the present invention is provided, and the direct heat engine system is described as follows according to the flow process:

[0031] 1. Medium and high temperature waste water enters the evaporator 30 through the water inlet pipe, and there is a water inlet regulating valve 31 on the water inlet pipe;

[0032] 2. The pressure in the evaporator 30 is lower than the saturation pressure corresponding to the temperature of the incoming medium-high temperature wastewater, so the medium-high temperature wastewater is partially evaporated immediately after entering the evaporator, which is also called flash evaporation or capacity expansion;

[0033] 3. The steam generated in the evaporator 30 enters the condenser 20 through the steam delivery channel 34;

[0034] 4. The rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com