Projection system of immersed photolithography system

An immersion lithography and projection system technology, applied in the field of projection systems, can solve problems such as residual water droplets, missing or distorted edges of photoresist layer graphics, and affecting the quality of edge imaging of projection systems, so as to prevent overflow and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

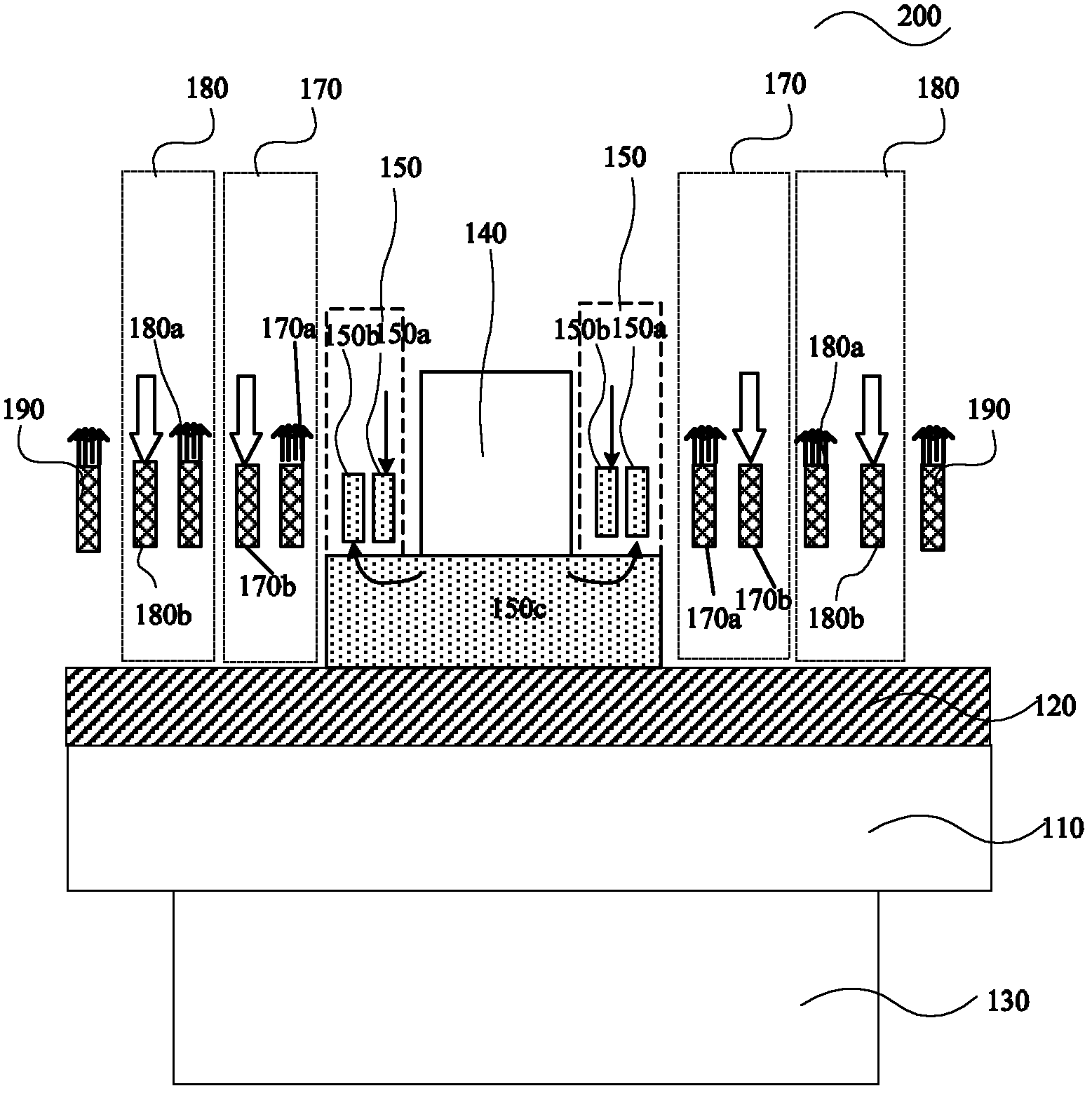

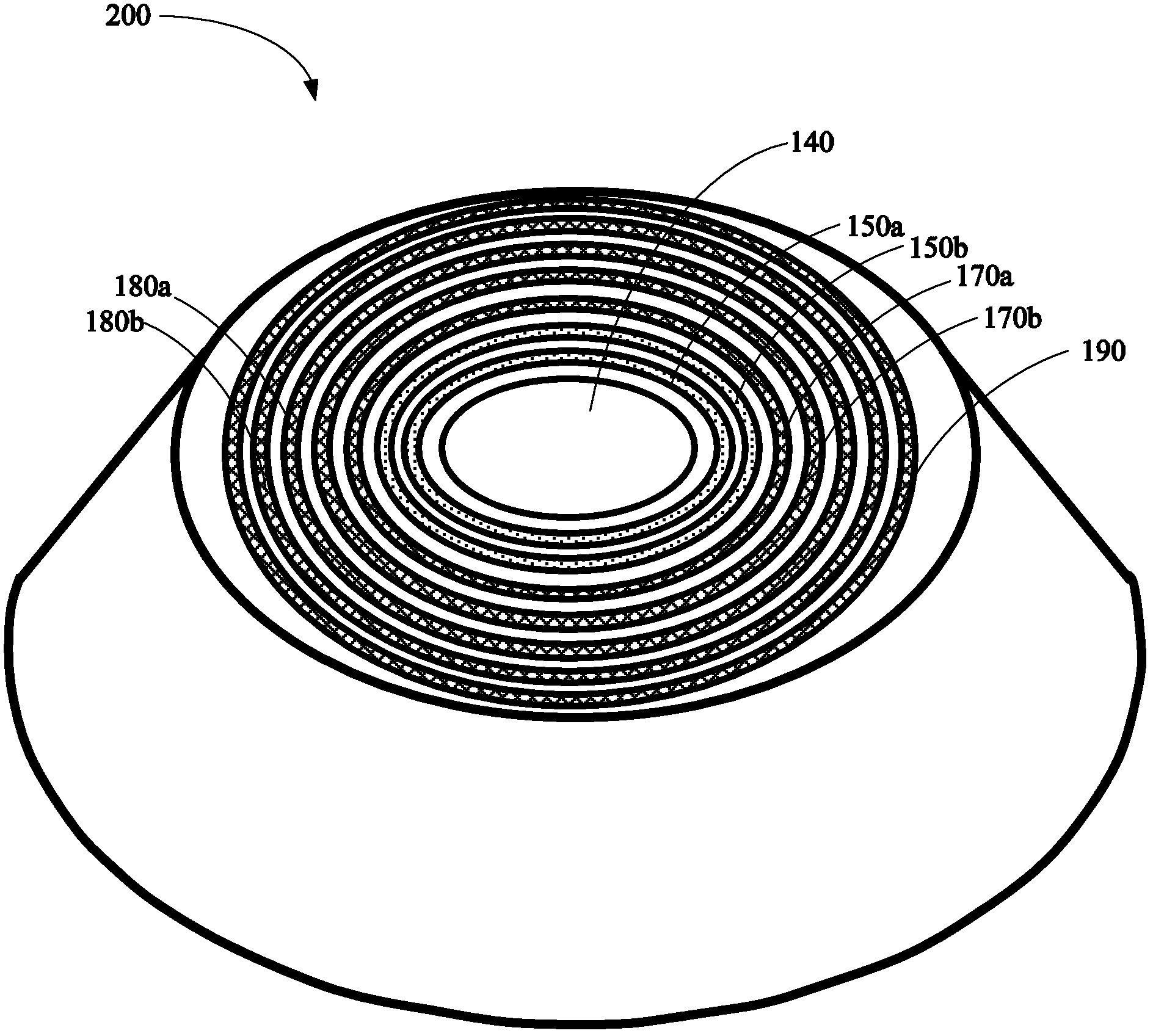

[0048] figure 2 It is a structural schematic diagram of the first embodiment of the projection system of the immersion lithography system of the present invention; image 3 It is a top view structure diagram of the first embodiment of the projection system of the immersion lithography system of the present invention.

[0049] to combine figure 2 and image 3 , The projection system 200 includes: a projection lens 140 , a liquid pool 150 c , a liquid supply device 150 , a first gas shower device 170 , a second gas shower device 180 and a suction device 190 .

[0050] Wherein, the projection lens 140 is used to scale down and project the pattern on the reticle onto the photoresist layer 120 on the semiconductor substrate 110 .

[0051] The liquid pool 150c is located in the exposure field of the projection lens 140 as the exposure medium of the projection lens 140; the projection lens 140 is immersed in the liquid pool 150c.

[0052] The liquid supply device 150 is located o...

Embodiment 2

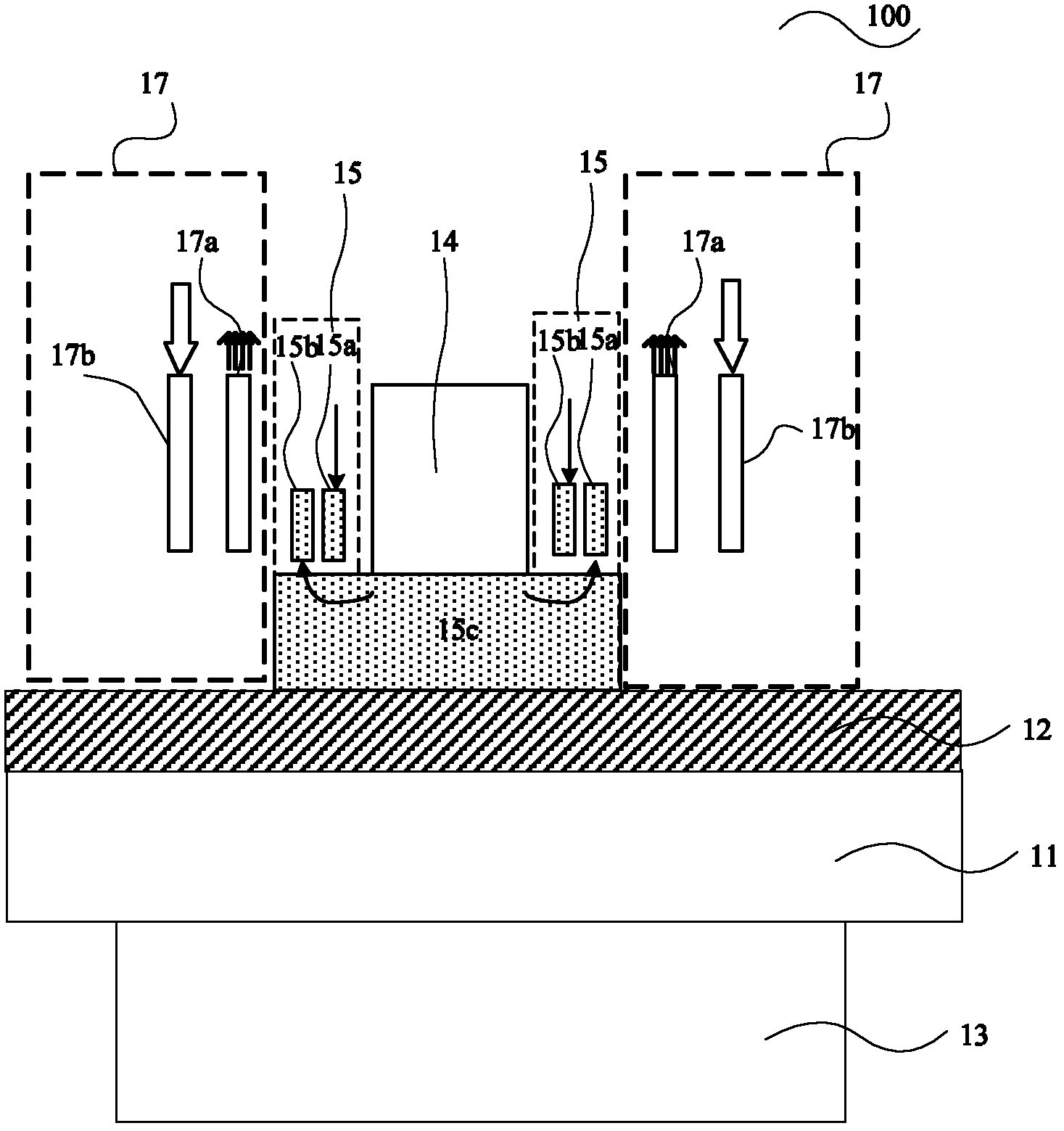

[0068] Figure 4 It is a structural schematic diagram of the second embodiment of the projection system of the immersion lithography system of the present invention.

[0069] like Figure 4 As shown, the projection system 300 includes: a projection lens 240 , a liquid pool 250 c , a liquid supply device 250 , a first gas shower device 270 , a second gas shower device 280 , a third gas shower device 290 and a suction device 260 .

[0070] Wherein, the projection lens 240 is used to scale down and project the pattern on the reticle onto the photoresist layer 220 on the semiconductor substrate 210 .

[0071] The liquid pool 250c is located in the exposure field of the projection lens 240 as the exposure medium of the projection lens 240; the projection lens 240 is immersed in the liquid pool 250c.

[0072] The liquid supply device 250 is located on the periphery of the projection lens, and is used for supplying liquid into the liquid pool 250c. The liquid supply device 250 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com