Preparation method of rare earth magnet

A technology of rare earth magnets and products, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve unknown problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

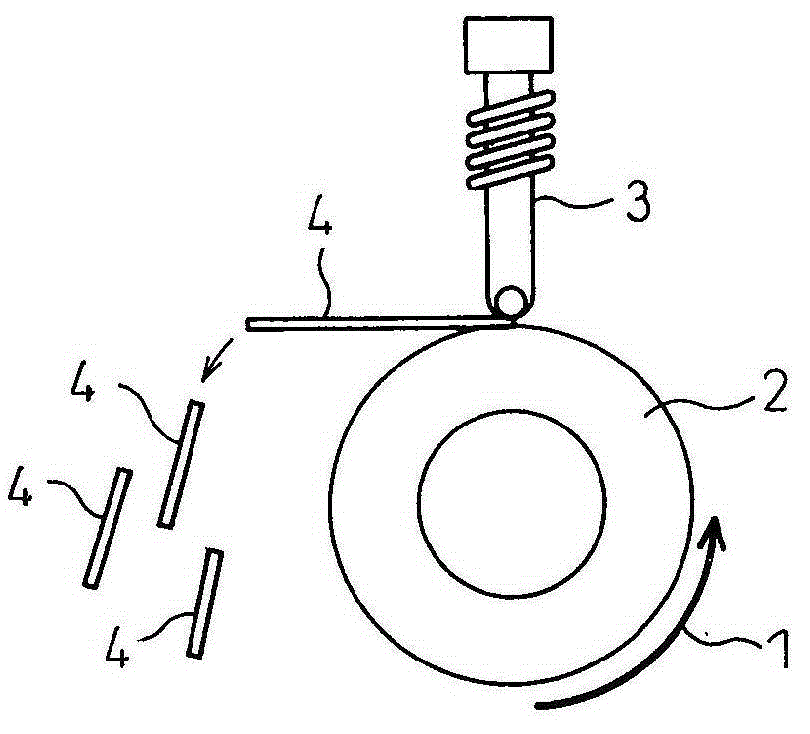

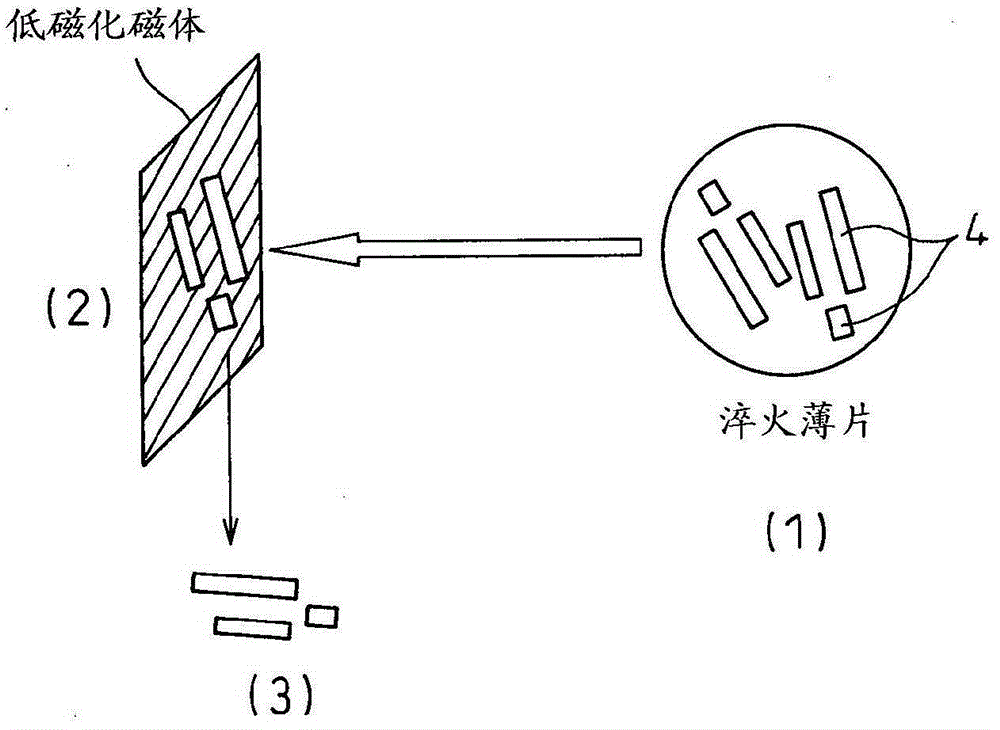

Method used

Image

Examples

no. 1 approach 》

[0047]

[0048] A representative example of the composition of a rare earth magnet is represented by the following composition formula:

[0049] R 1 v Fe w co x B y m 1 z

[0050] R 1 : one or more rare earth elements including Y,

[0051] m 1 : at least one of Ga, Zn, Si, Al, Nb, Zr, Ni, Cu, Cr, Hf, Mo, P, C, Mg and V,

[0052] 13≤v≤20,

[0053] w=100-v-x-y-z,

[0054] 0≤x≤30,

[0055] 4≤y≤20,

[0056] 0≤z≤3.

[0057] Preferably, in the composition formula R 1 v Fe w co x B y m 1 z in, R 1 The amount v of (one or more rare earth elements including Y) is 13≦v≦17, and the amount y of B is 5≦y≦16.

[0058] Another representative example of the composition of the rare earth magnet is represented by the following composition formula, and consists of the main phase ((R 2 R 3 ) 2 (FeCo) 14 B) and grain boundary phase ((R 2 R 3 )(FeCo) 4 B 4 Phase and R 2 R 3 phase) composition:

[0059] R 2 a R 3 b Fe c co d B e m 2 f

[0060] R 2 : one o...

no. 2 approach 》

[0109]

[0110] The film with the rare earth magnet composition is deposited on the substrate by any type of method such as chemical vapor deposition (CVD) and physical vapor deposition (PVD). The thickness of the film may be 0.50 μm or more, 1.00 μm or more, 2.00 μm or more, or 3.00 μm or more. In addition, the thickness of the film may be 1000 μm or less, 100 μm or less, 50 μm or less, or 10 μm or less.

[0111]

[0112] After the film is deposited, heat treatment under pressure is applied, which is a characteristic feature of the present invention. To this end, the difference in the thermal expansion coefficients of the substrate and the film deposited thereon can be exploited.

[0113] The pressure applied to the film during the pressurized heat treatment may be 1 MPa or more, 5 MPa or more, 10 MPa or more, 50 MPa or more, or 100 MPa or more, and may be 300 MPa or less, 400 MPa or less, or 500 MPa or less. The pressure heat treatment time may be 1 minute or more, 3 m...

Embodiment

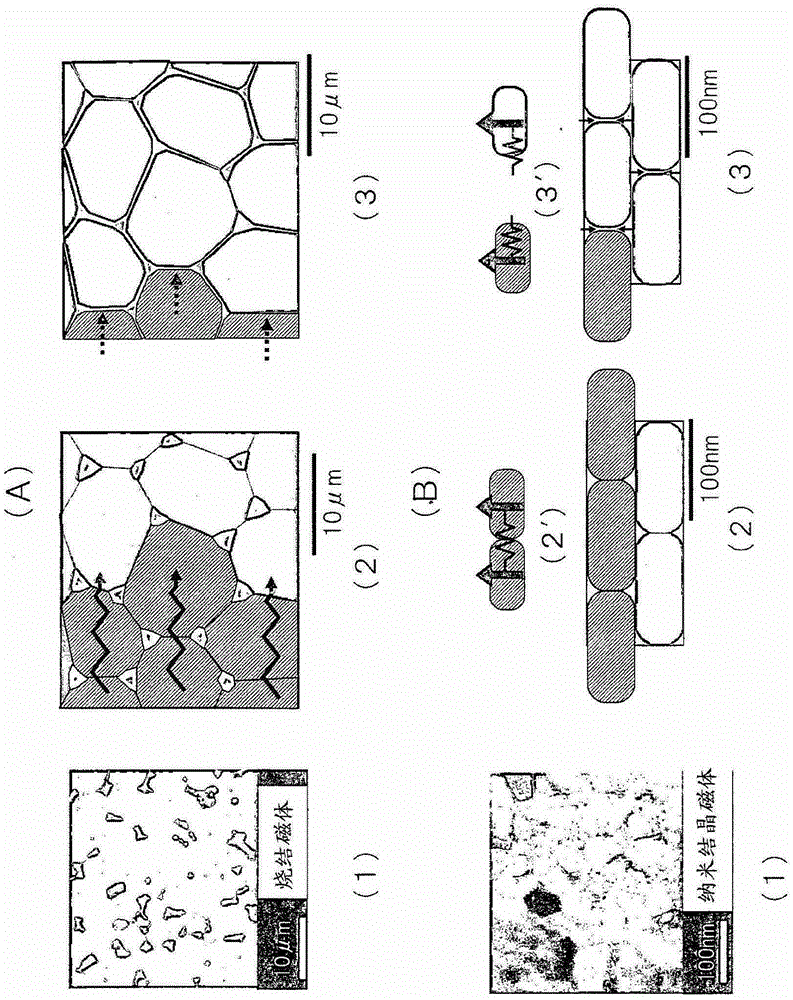

[0116] [Reference Example 1-4]

[0117] It was confirmed in Reference Examples 1-4 below that rare earth magnets with improved magnetic coercive force were obtained in the method of the present invention for producing rare earth magnets compared to conventional methods not involving heat treatment, even when heat treatment was not accompanied by the addition of The same is true when pressing.

[0118] [Reference Example 1]

[0119] The preparation composition is Nd 15 Fe 77 B 7 Ga 1 Nanocrystalline rare earth magnets and compositions containing Al and Cu, that is, Nd 15 Fe 77 B 6.8 Ga 0.5 Al 0.5 Cu 0.2 nanocrystalline rare earth magnets. The final structure is composed of the main phase: Nd 2 Fe 14 B 1 Phase and grain boundary phase: Nd-rich phase (Nd or Nd oxide) or Nd 1 Fe 4 B 4 Phase composition of nanocrystalline structure. Ga is enriched in the grain boundary phase to prevent movement of grain boundaries and suppress coarsening of crystal grains. Both A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com