Multi-mode water mist fire extinguishing system

A fire-extinguishing system and multi-mode technology, applied in the field of fire-fighting equipment, can solve the problems of not being isolated, the joint and the hose being separated, and the spray angle and spray distance cannot be adjusted according to the fire situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

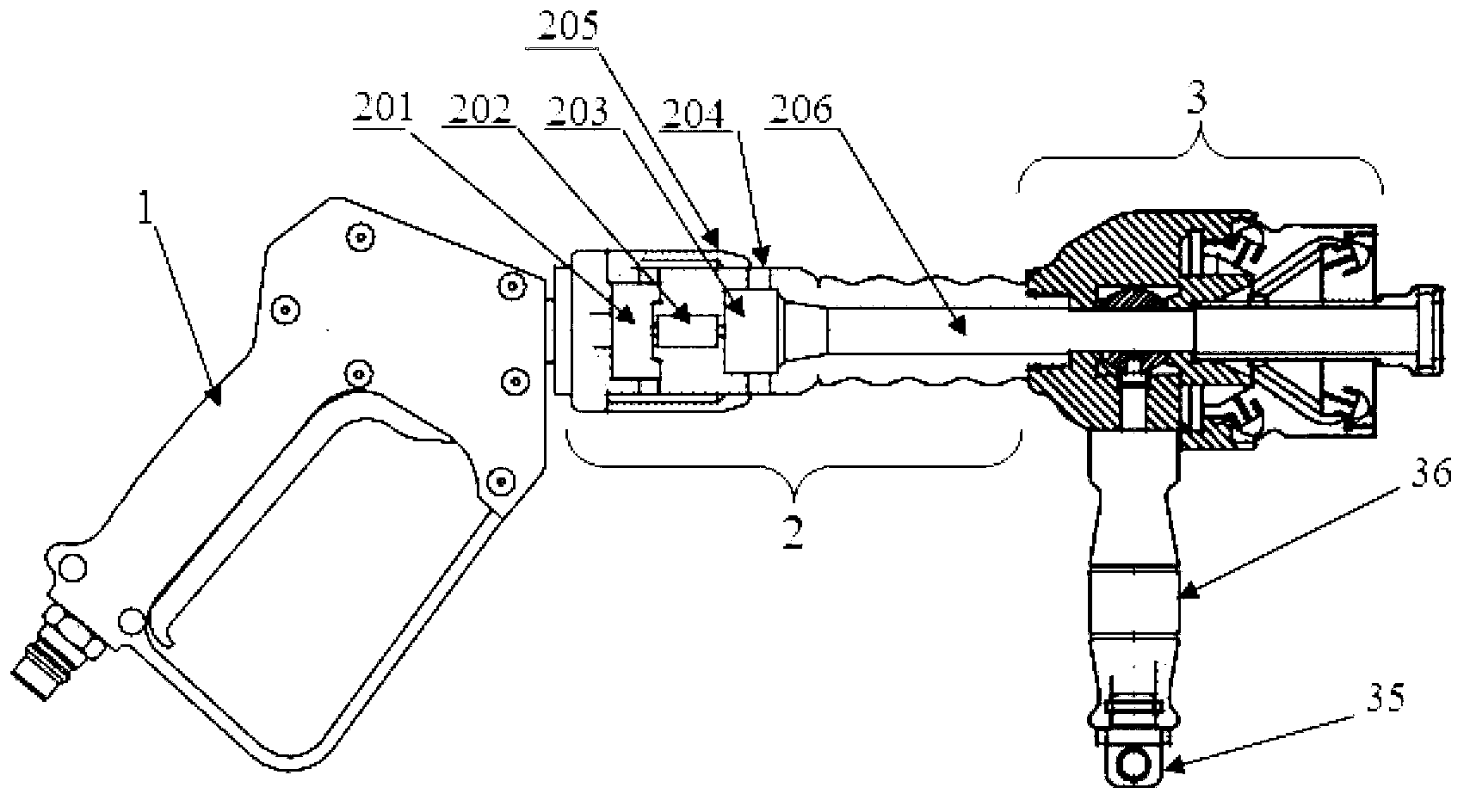

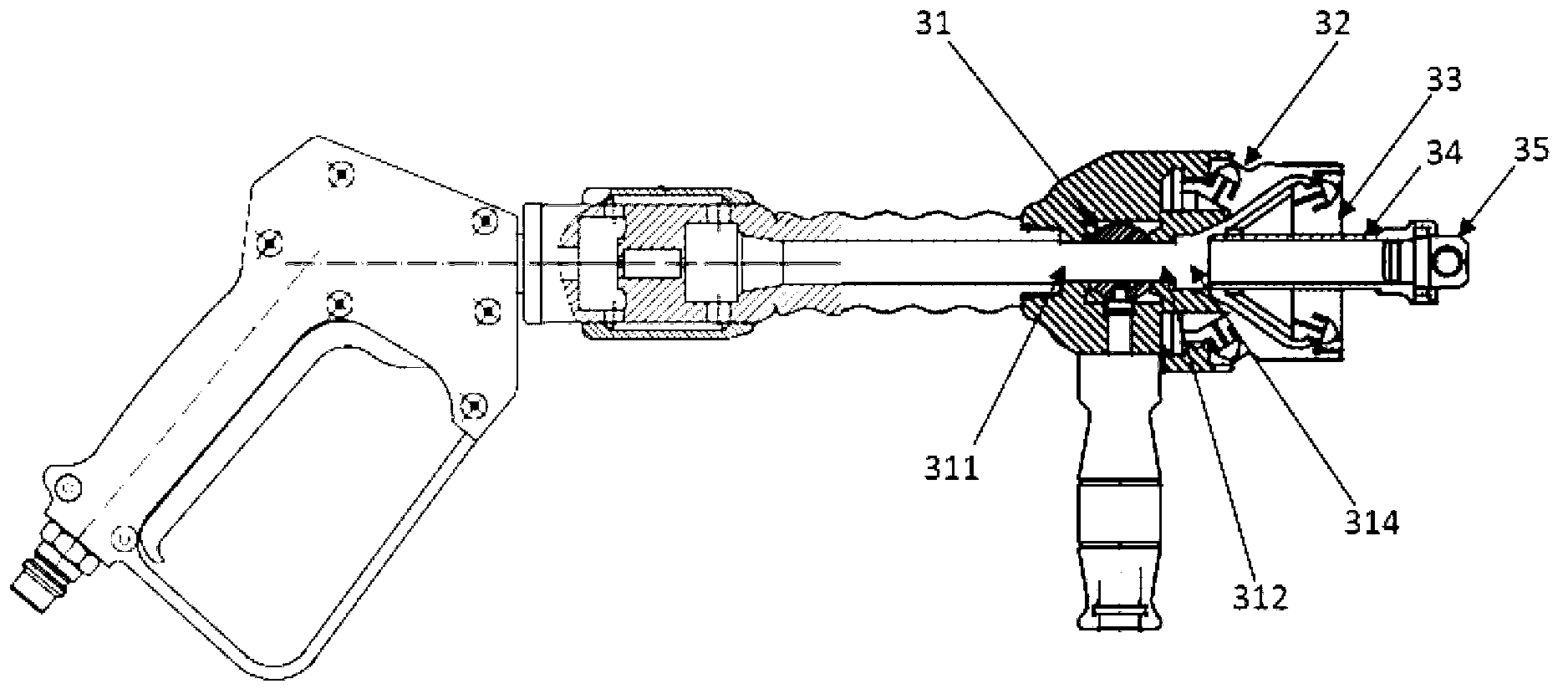

[0039] Such as Figure 10 As shown, the multi-mode water mist fire extinguishing system mentioned in the present invention mainly includes a water pump unit, a water delivery pipeline group mainly composed of a high-pressure water belt, and a spray gun.

[0040] As shown in the figure, the spray gun of this embodiment is a spray gun with multiple spray modes, including a spray gun handle 1 with a switch at the rear end, an intermediate pipe 2 at the middle, and a multi-mode water mist nozzle group 3 at the front end;

[0041] Among them, the water flow channel in the middle pipe 2 is divided into a coaxial pre-splitting chamber 201, a direct current steady flow chamber 202, an air-water mixing chamber 203, and a mixed flow chamber 206 from the back to the front; the direct current steady flow chamber 202 and the air-water mixing chamber The channel opening between 203 is coaxial with the intermediate pipe, and its diameter is smaller than the diameter of the mixed flow chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com