Method for removing bivalent copper ions in aqueous solution

A copper ion, aqueous solution technology, applied in ion exchange, ion exchange regeneration, chemical instruments and methods, etc., can solve the problems of weak adsorption performance, weak bonding force, limited number and other problems, and achieve the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

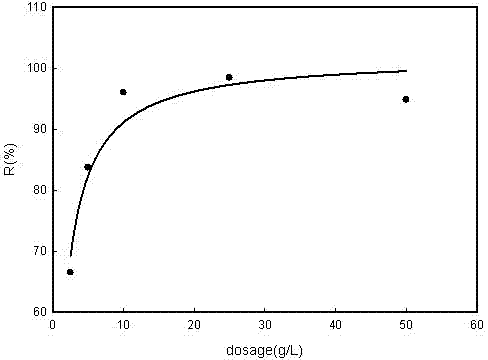

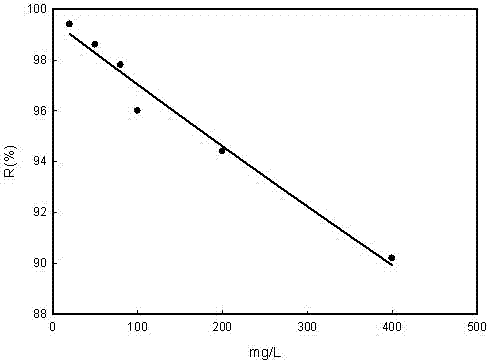

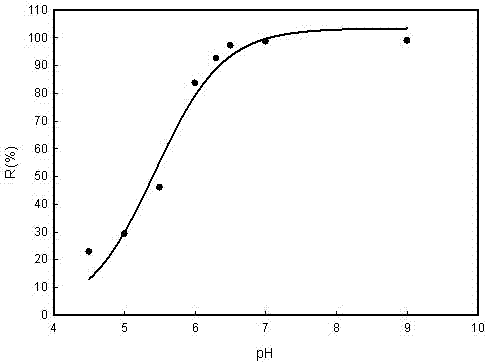

Method used

Image

Examples

Embodiment approach 1

[0031] (1) Prepare 0.4mol / L AlCl 3 solution, at a temperature of 55°C, add 0.4mol / L sodium hydroxide solution dropwise to AlCl at a rate of 1mL / min 3 solution until n(OH - ) : n(Al 3+ ) = 2.4, then aged at 55°C for 47h to obtain a polyhydroxyaluminum pillaring agent; take 1g of sodium bentonite, and add the polyhydroxyaluminum pillaring agent to the bentonite at a ratio of Al / soil of 10mmol / g, 55 Stir at ℃ for 3.5 hours, cool to room temperature, filter under reduced pressure, wash with distilled water until neutral, then filter with suction, dry the obtained filter cake at 40℃, grind to obtain polyhydroxyaluminum cross-linked bentonite, and set aside;

[0032] (2) Dissolve chitosan in an acetic acid solution with a mass fraction of 4%, the ratio is 1g of chitosan dissolved in 30 ml of an acetic acid solution with a mass fraction of 4%; place the prepared mixed solution in a stirring Add liquid paraffin to the three-necked flask with a thermometer and a thermometer, the rat...

Embodiment approach 2

[0038] (1) Prepare 0.4mol / L AlCl 3 solution, at a temperature of 65°C, add 0.4mol / L sodium hydroxide solution dropwise to AlCl at a rate of 1mL / min 3 solution until n(OH - ) : n(Al 3+ ) = 2.4, then aged at 65°C for 49h to obtain a polyhydroxyaluminum pillaring agent; take 1g of sodium bentonite, and add the polyhydroxyaluminum pillaring agent to the bentonite at a ratio of Al / soil of 10mmol / g, 65 Stir at ℃ for 4.5 hours, cool to room temperature, filter under reduced pressure, wash with distilled water until neutral, then filter with suction, dry the obtained filter cake at 70 ℃, grind to obtain polyhydroxyaluminum cross-linked bentonite, and set aside;

[0039] (2) Dissolve chitosan in an acetic acid solution with a mass fraction of 6%, and the ratio is to dissolve 1g of chitosan into 35ml of an acetic acid solution with a mass fraction of 6%; place the prepared mixed solution in a stirrer Add liquid paraffin to the three-necked flask with a thermometer, the ratio is 1g ch...

Embodiment approach 3

[0045] (1) Prepare 0.4mol / L AlCl 3 solution, at a temperature of 60°C, add 0.4mol / L sodium hydroxide solution dropwise to AlCl at a rate of 1mL / min 3 solution until n(OH - ) : n(Al 3+ ) = 2.4, then aged at 60°C for 48h to obtain a polyhydroxyaluminum pillar proppant; take 1g of sodium bentonite, add the polyhydroxyaluminum pillar proppant to the bentonite at a ratio of Al / soil of 10mmol / g, 60 Stir at a temperature of ℃ for 4 hours, cool to room temperature, filter under reduced pressure, wash with distilled water until neutral, then filter with suction, dry the obtained filter cake at 60 ℃, and grind to obtain polyhydroxyaluminum cross-linked bentonite, which is ready for use;

[0046] (2) Dissolve chitosan in an acetic acid solution with a mass fraction of 5%, the ratio is 1g of chitosan dissolved in 33ml of an acetic acid solution with a mass fraction of 5%; Add liquid paraffin to the three-necked flask with a thermometer, the ratio is 1g chitosan to 33ml liquid paraffin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com