UV (Ultraviolet) curing optical film production device

A technology for optical flakes and production equipment, which is applied to other household appliances, household appliances, flat products, etc., can solve the problems of large size and small size of microprisms, achieve good consistency, reduce temperature difference, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

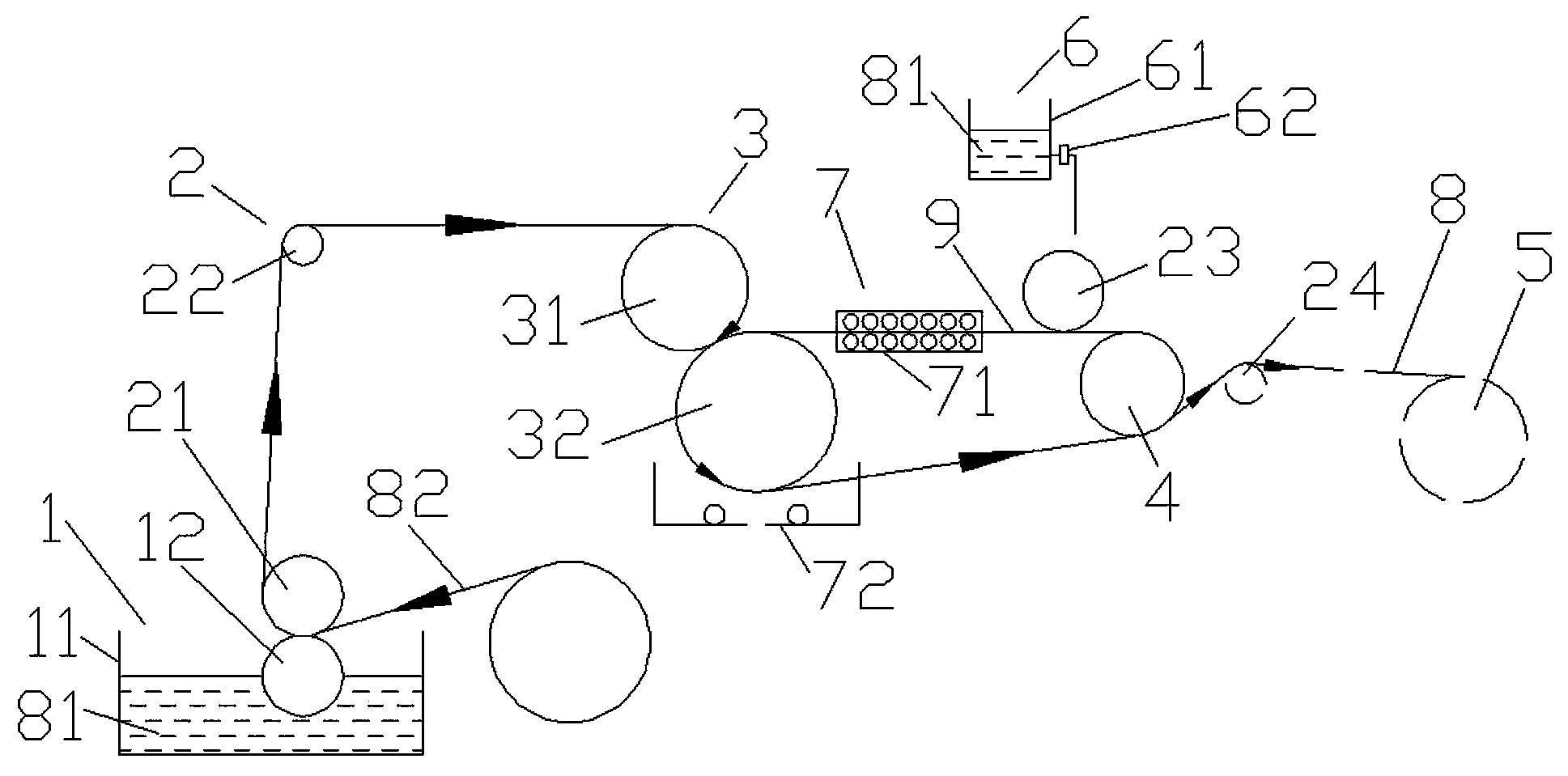

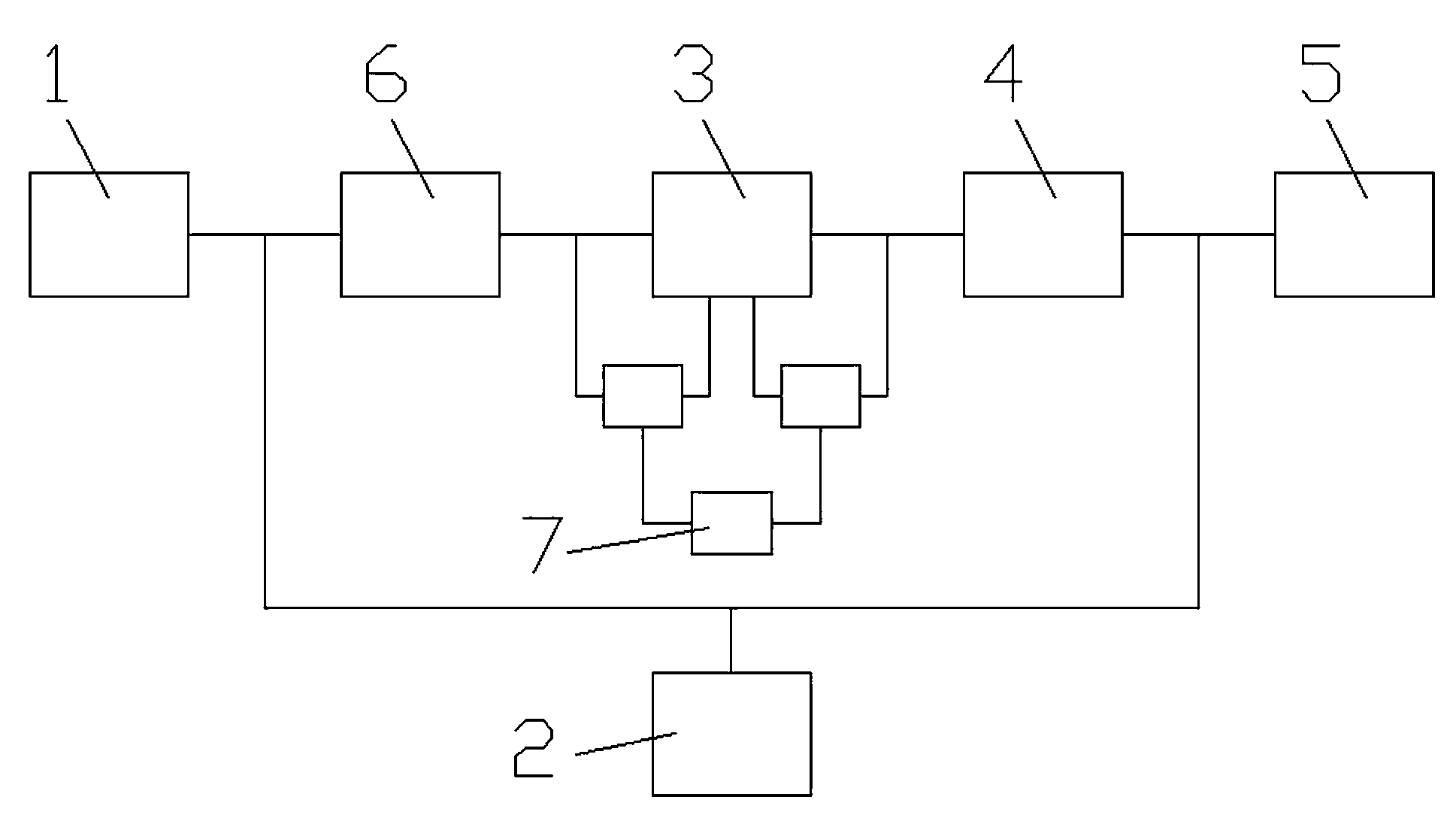

[0017] The present invention can be further understood through the examples of the present invention given below, but the protection of the present invention is not limited to a UV-curable optical sheet production equipment, including a coating device (1), a transmission device (2), a heating film press device (3), cooling roll (4) and winding device (5), the coating device (1) is coated with photosensitive resin (81) on one side surface of resin film (82), coated with photosensitive The resin film (82) of the resin (81) is transmitted to the heating film pressing device (3) through the transmission device (21), and the heating film pressing device (3) includes a pressing roller (31) and a heating roller (32) , the outer surface of the heating roller (32) and the cooling roller (4) is covered with a conveyor belt (9), and the outer surface of the conveyor belt (9) is provided with an annular microprism mold, the heating roller (32), the The cooling roller (4) and the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com