Automatic spraying-control device for coal-conveying belt in mine shaft

A spray control and belt technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve life-threatening and production safety, affect workers' health, environmental pollution and other problems, achieve reasonable structure, simple implementation, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

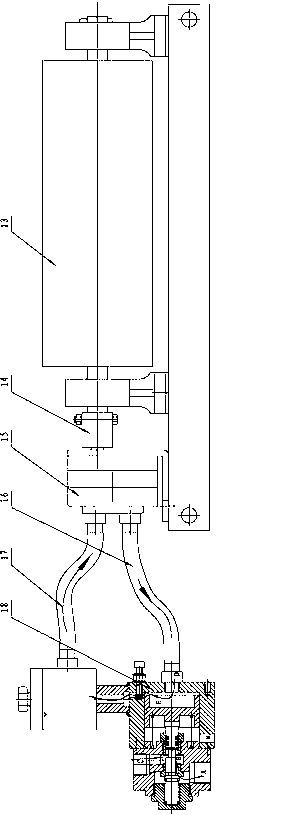

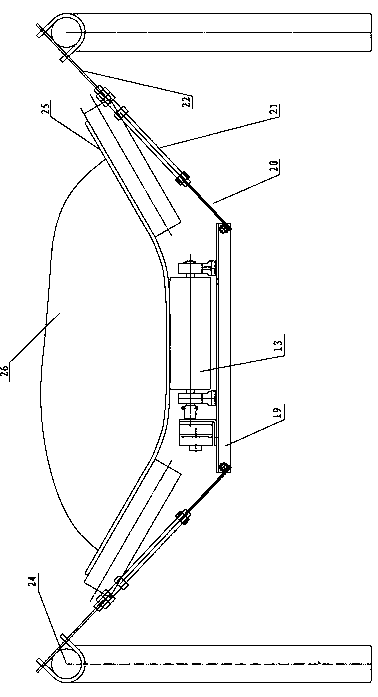

[0021] Please refer to the manual attached figure 1 to the attached image 3 As shown, the present invention is an automatic spray control device for coal conveying belts in mines, which consists of friction rollers 13, coupling sleeves 14, gear pumps 15, oil inlet pipes 16, oil outlet pipes 17 and controller 18.

[0022] Wherein, the gear pump 15 is linked to the friction roller 13 through the connecting sleeve 14; the oil inlet pipe 16 and the oil outlet pipe 17 are respectively connected to the gear pump 15; the controller 18 is respectively connected to the oil inlet pipe 16, Outlet pipe 17.

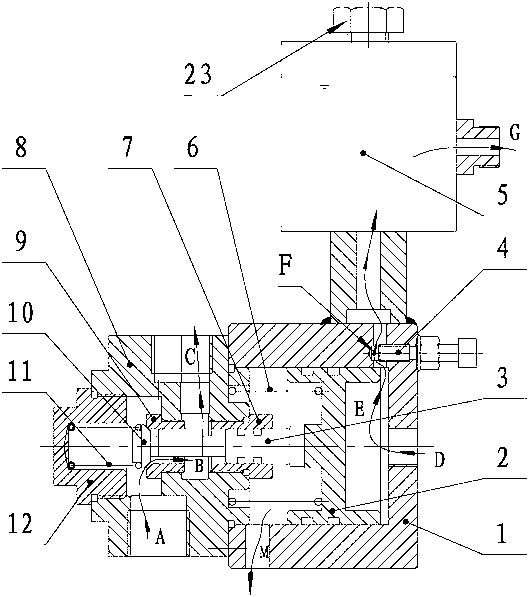

[0023] Further, the controller 18 includes a piston cylinder 1, a piston 2, a push rod 3, a pressure regulating screw 4, an oil storage tank 5, a piston spring 6, a push rod guide nut 7, a water inlet and outlet seat 8, and a valve core nut 9 , Guide spool 10 , spool spring 11 and end cap nut 12 . The piston 2 and the piston spring 6 are loaded into the piston cylinder 1 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com