Elevator hydraulic buffer resetting performance dynamic measuring method and tester adopted by method

A technology of hydraulic buffer and measurement method, applied in elevators, transportation and packaging, etc., can solve problems such as inapplicability of elevator inspection rules, failure to fully reflect the dynamic process of elevator buffers, and errors in measurement results, etc. Easy to install and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In this embodiment, the laser ranging module is adopted as a laser rangefinder whose model is LRFS (HYKOL)-0040-1 / 2, the ultrasonic ranging module is an ultrasonic rangefinder whose model is KS103, and the wireless data module whose model is APC220-43 The transfer module is described below.

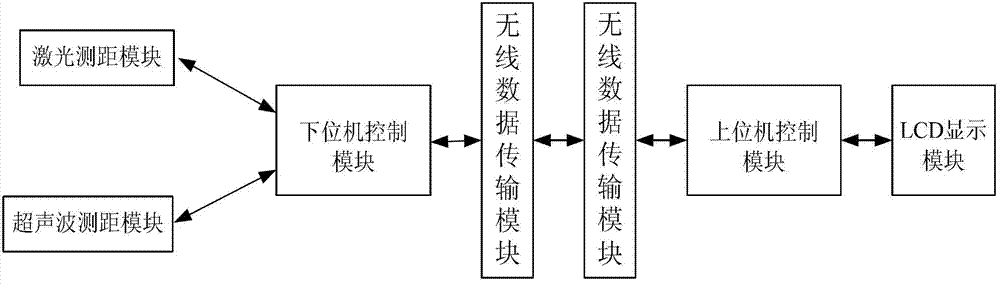

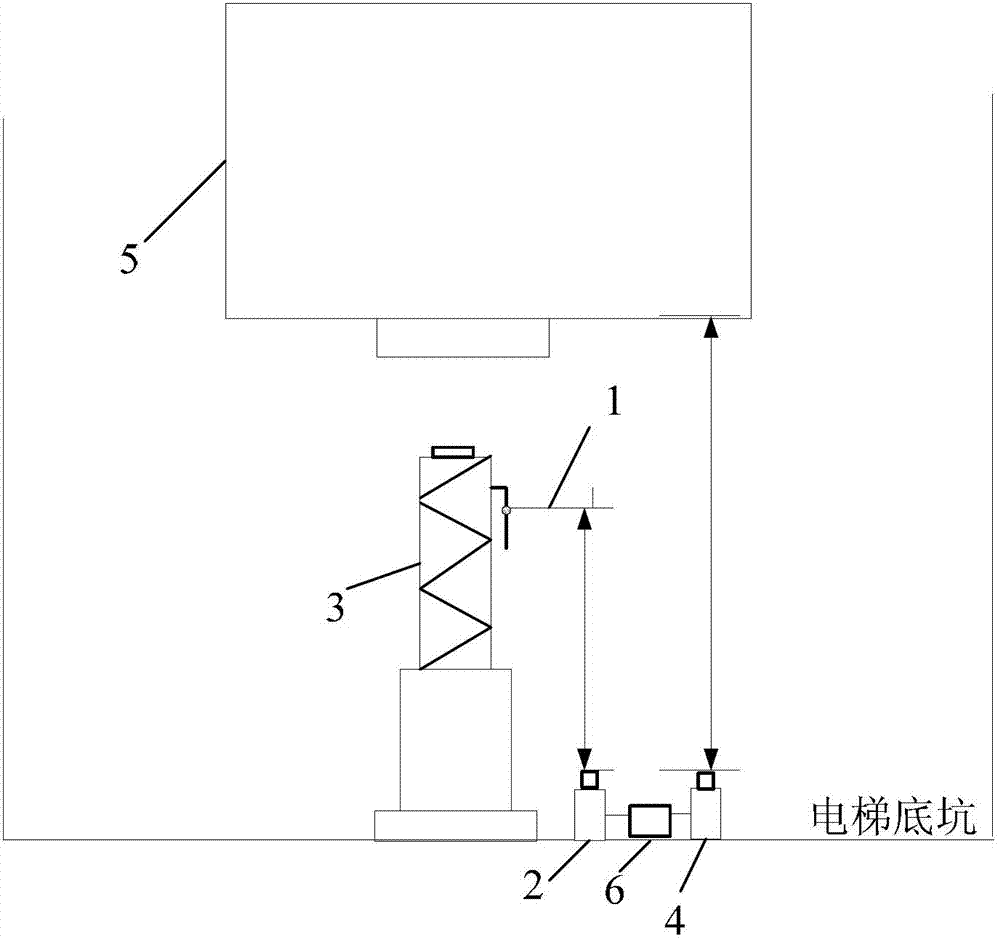

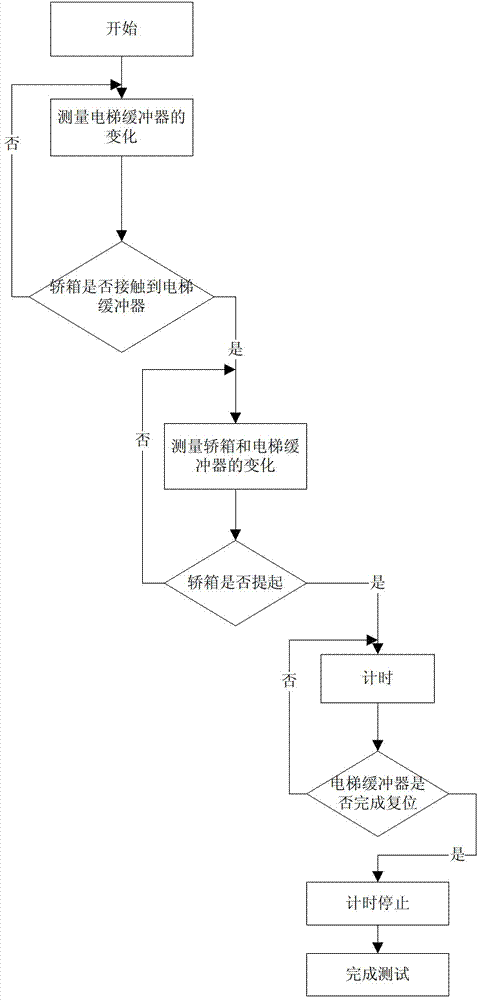

[0044] The module structure diagram of the elevator hydraulic buffer reset performance dynamic tester of the present invention is as follows figure 1 As shown, the tester includes a baffle, a laser distance measuring module for measuring the distance change between the baffle and the elevator pit floor, and an ultrasonic distance measuring module for measuring the distance change between the elevator car and the elevator pit , used to save data in real time, receive feedback signals from the laser ranging module and ultrasonic ranging module, and control the lower computer control module of the laser ranging module and ultrasonic ranging module, used to receive feedback information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com